Gas well liquid-carrying mechanism visualization simulation experiment device of complex structural well

A technology that simulates experimental devices and complex structures. It is used in construction and other directions. It can solve the problems of single linear injection of liquid and lack of extensiveness, and achieve the effect of accurate results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

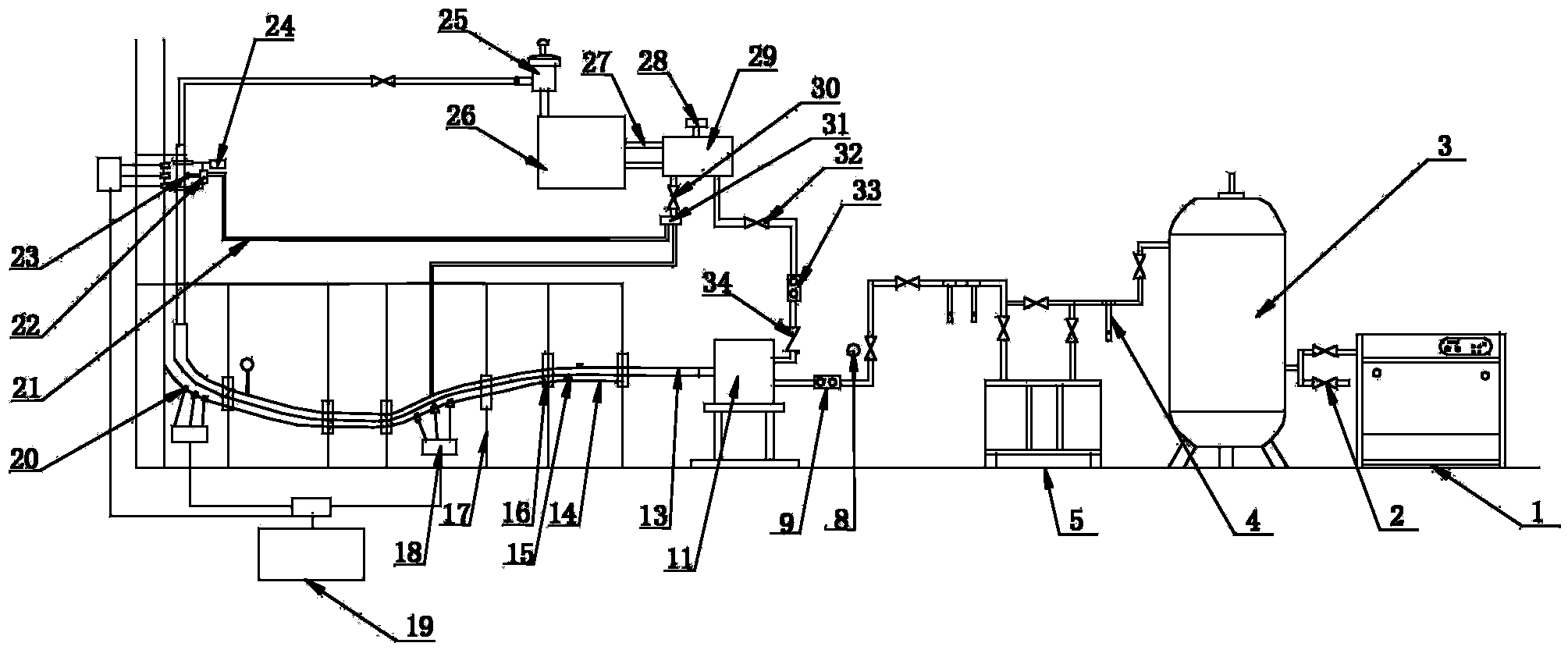

[0020] Embodiment 1, before the experiment starts, the first liquid throttling valve 30 and the second liquid throttling valve 32 are closed. At the beginning of the experiment, the air compressor 1 injects compressed gas into the air storage tank 3, and the compressor 1 and the air storage tank 3 are a linkage device, that is, when the pressure of the air storage tank 3 is lower than the set value, the compressor 1 will automatically turn on the air storage tank 3. The air tank 3 replenishes the air to ensure the stability of the experimental air source. The pressure used in the experiment can be recorded by the pressure gauge 8, and the experimental gas flow rate can be measured by the gas flow meter 9. Turn on the booster pump 29 to adjust the pressure to the pressure required for the experiment. Open the intake throttle valve to inject gas into the wellbore. The pressure of the injected gas can be changed by adjusting the intake throttle valve. The liquid throttling val...

Embodiment 2

[0021] Example 2, before the start of the experiment, adjust the height of each section of the horizontal section to keep it basically level. The first liquid throttle valve 30 and the second liquid throttle valve 32 are closed. At the beginning of the experiment, the air compressor 1 injects compressed gas into the air storage tank 3, and the compressor 1 and the air storage tank 3 are a linkage device, that is, when the pressure of the air storage tank 3 is lower than the set value, the compressor 1 will automatically turn on the air storage tank 3. The gas tank 2 replenishes the gas to ensure the stability of the experimental gas source. The pressure used in the experiment can be recorded by the pressure gauge 8, and the experimental gas flow rate can be measured by the gas flow meter 9. Turn on the booster pump 29 to adjust the pressure to the pressure required for the experiment. Open the intake throttle valve and inject gas into the wellbore. The pressure of the injec...

Embodiment 3

[0022]Embodiment 3, before the start of the experiment, adjust the height of each section of the horizontal section to maintain a certain inclination angle between each section. Close the first liquid throttle valve 30 and the second liquid throttle valve 32 . At the beginning of the experiment, the air compressor 1 injects compressed gas into the air storage tank 3, and the compressor 1 and the air storage tank 3 are a linkage device, that is, when the pressure of the air storage tank 3 is lower than the set value, the compressor 1 will automatically turn on the air storage tank 3. The gas tank 2 replenishes the gas to ensure the stability of the experimental gas source. The pressure used in the experiment can be recorded by the pressure gauge 8, and the experimental gas flow rate can be measured by the gas flow meter 9. Turn on the booster pump 29 to adjust the pressure to the pressure required for the experiment. Open the intake throttle valve and inject gas into the well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com