Central distribution manifold with hermetically butt-connected screwed nipples

A threaded joint and threaded connection technology, which is applied in the direction of pipes/pipe joints/fittings, non-detachable pipe connections, passing components, etc., can solve the problems of unstable welding quality, low processing efficiency, and high difficulty, and achieve fast and efficient processing. Accurate, ensure welding quality, simplify the effect of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

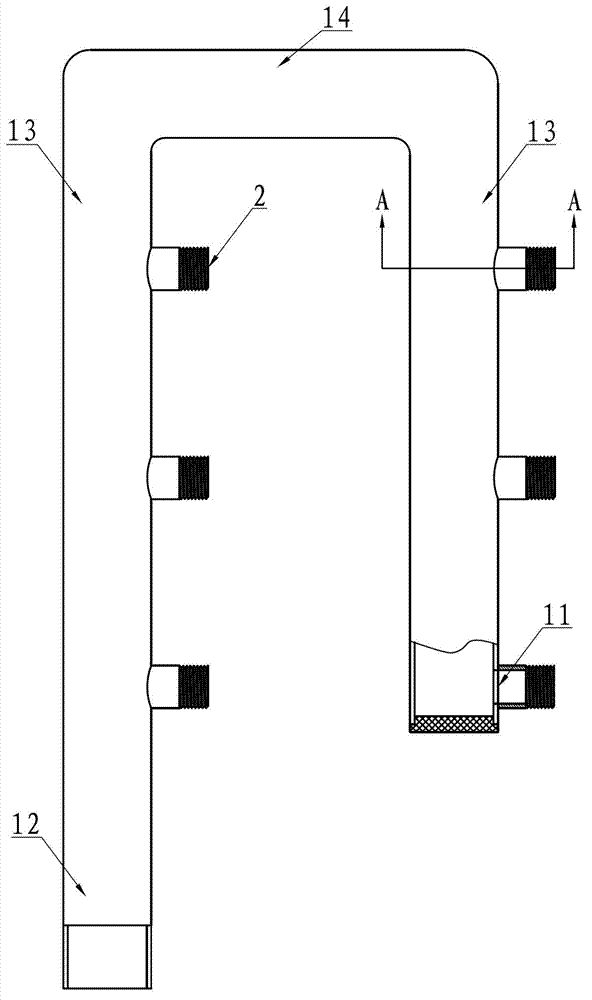

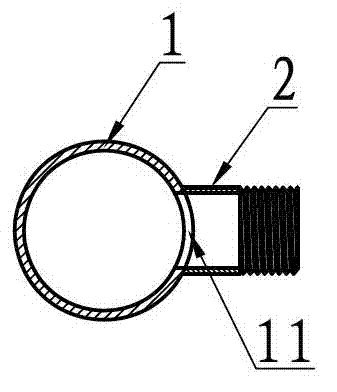

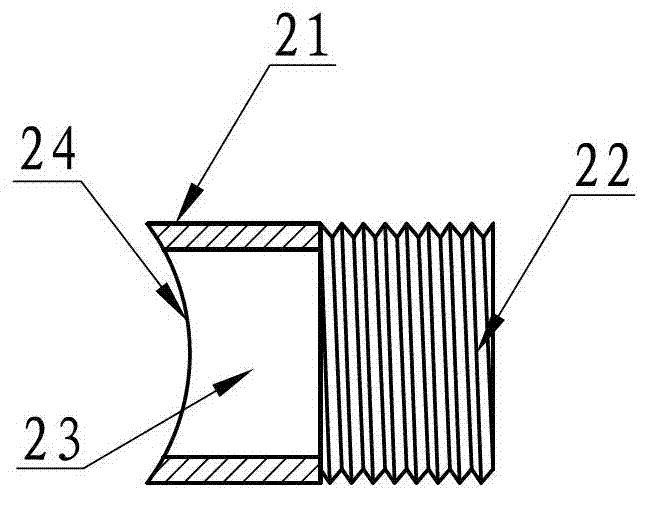

[0015] A centralized gas distribution manifold with anastomotic and sealed butt joints of threaded joints, such as Figure 1~3 As shown, the intake manifold 1 and the threaded joint 2 are included. The intake manifold 1 includes the intake pipe section 11, the meter connecting pipe section 12 and the connecting pipe section 13. The threaded joints 2 are welded and connected to the meter connecting pipe section 12 at equal intervals. The threaded joint 2 includes an arc joint end 21, a threaded connection end 22 and a joint inner hole 23, the joint inner hole 23 is arranged at the center of the threaded connection end 22, and the diameter of the butt joint arc surface 24 of the arc joint end 21 is in line with the intake port. The pipes 1 have the same diameter, and the threaded joint 2 is butted on the intake manifold 1 through the butt arc surface 24 of the arc joint end 21, and the two are sealed and fixedly welded into one body through the annular weld 3. The joint inner ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com