Marine rig derrick stress test tool

A technology of stress testing and drilling rigs, which is applied in the direction of measuring devices, measuring forces, instruments, etc., can solve the problems of inconvenient testing and high structural weight, and achieve the effects of ensuring test safety, reducing the weight of the main beam, and reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

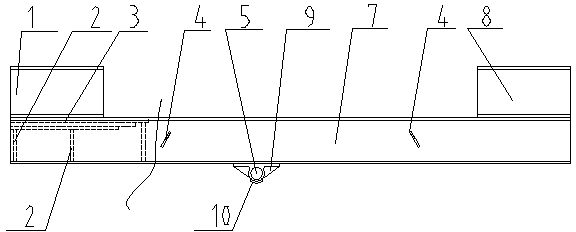

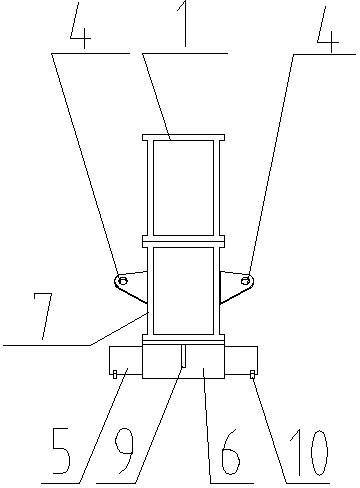

[0014] The offshore drilling rig derrick stress test tooling consists of a main beam 7, a left support block 1, a right support block 8, a main lifting lug 6, an auxiliary lifting lug 4, a load bearing shaft 5, a backing plate 3 and a support reinforcement plate 2. The two ends of the upper surface of the main beam 7 are symmetrically welded with a left support block 1 and a right support block 8, the main beam 7, the left support block 1 and the right support block 8 are box-shaped structures respectively, and the left support block 1 and the right support block 8 Align with the border of the main beam 7. The effect of left support block 1 and right support block 8 is to provide tooling and the contact surface of derrick when loading.

[0015] The two sides of the main beam 7 between the left support block 1 and the right support block 8 are symmetrically welded with auxiliary lifting lugs 4. The auxiliary lifting lugs 4 are plate-type lifting lugs, and the material is Q345B....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com