Cabling pay-off machine with lifting structure

A lifting structure and pay-off machine technology, applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of cable damage, time-consuming and labor-intensive operation, and unusable cables, so as to improve work efficiency and transmission stability Good, guarantee the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

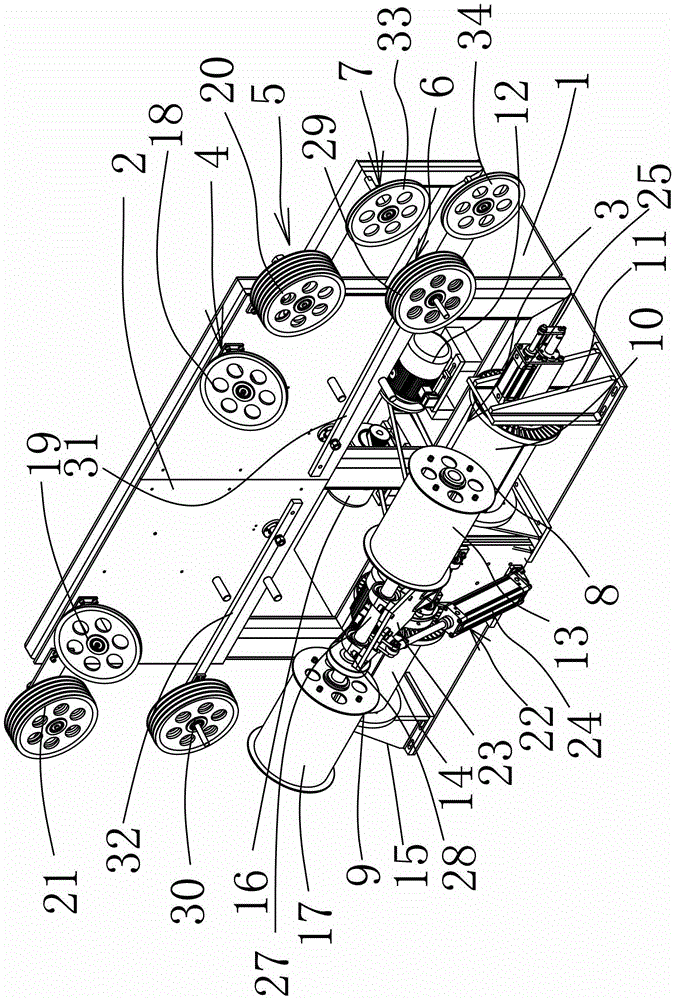

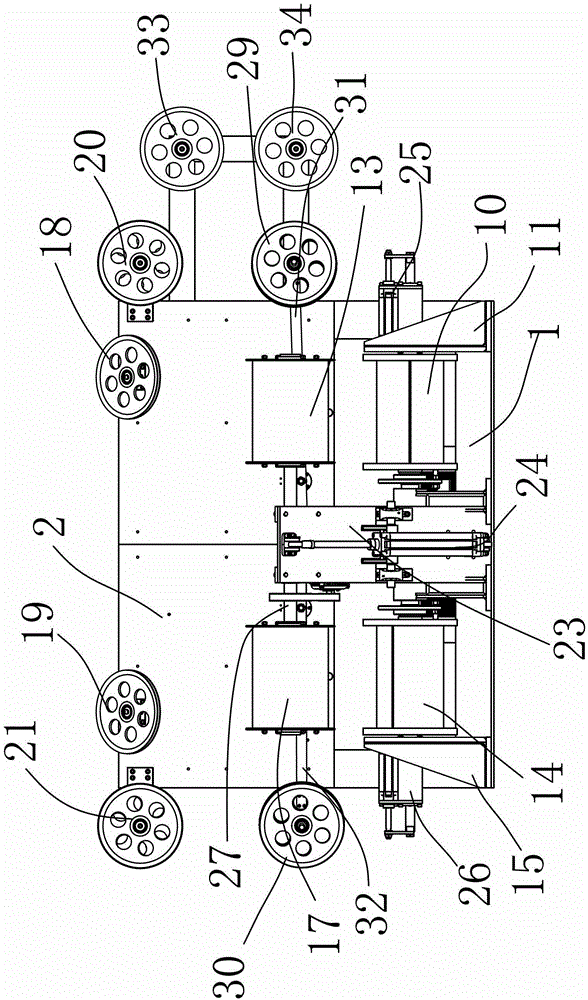

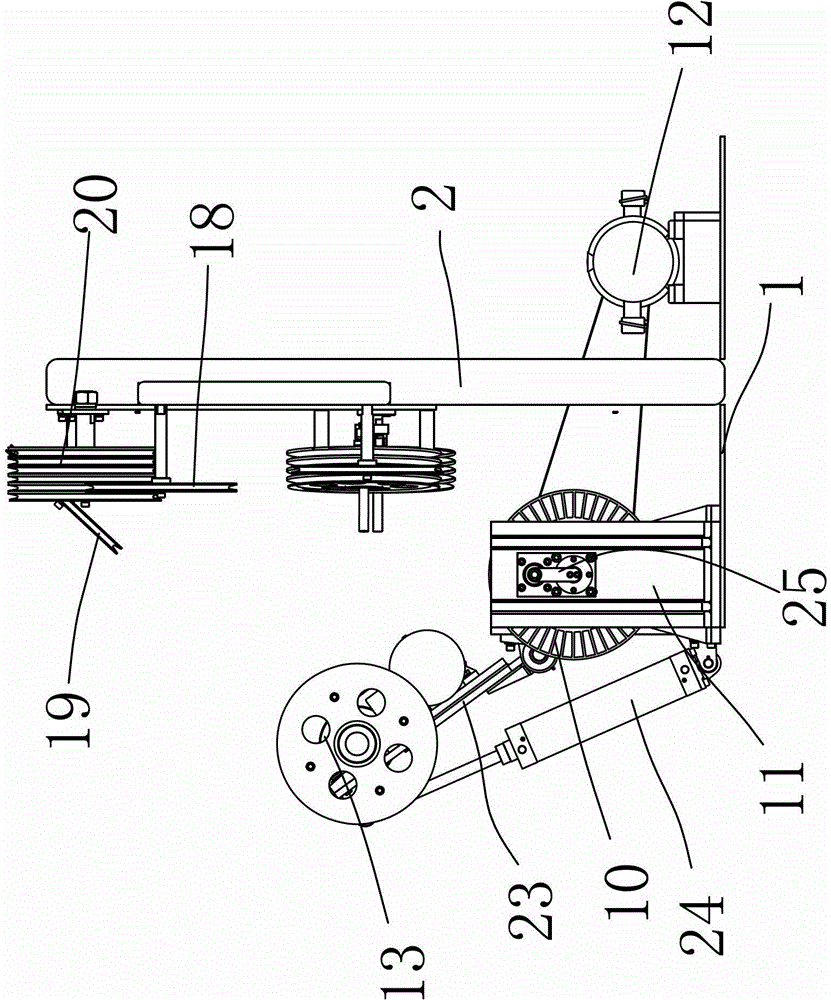

[0023] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

[0024] In the figure, the frame 1; the fixed plate 2; the pay-off mechanism 3; the pay-off guide mechanism 4; the pay-off transition mechanism 5; the tension control mechanism 6; the outlet mechanism 7; the right pay-off mechanism 8; the left pay-off mechanism 9; One pay-off reel 10; first pay-off support 11; first pay-off drive motor 12; first pay-off reel wheel 13; second pay-off reel 14; second pay-off support 15; second pay-off drive motor 16 ; The second pay-off reel 17; the first tangential reel 18; the second tangential reel 19; the first transition reel 20; the second transition reel 21; the pay-off reel lifting mechanism 22; lift The fixed platform 23; lift the driving cylinder 24; the first installation driving cylinder 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com