A method for replacing an anti-vibration hammer

A replacement method and anti-vibration hammer technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems that the replacement operation cannot be completed in time and the safety risk is high, and achieve the effect of reducing direct economic losses, labor intensity and labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

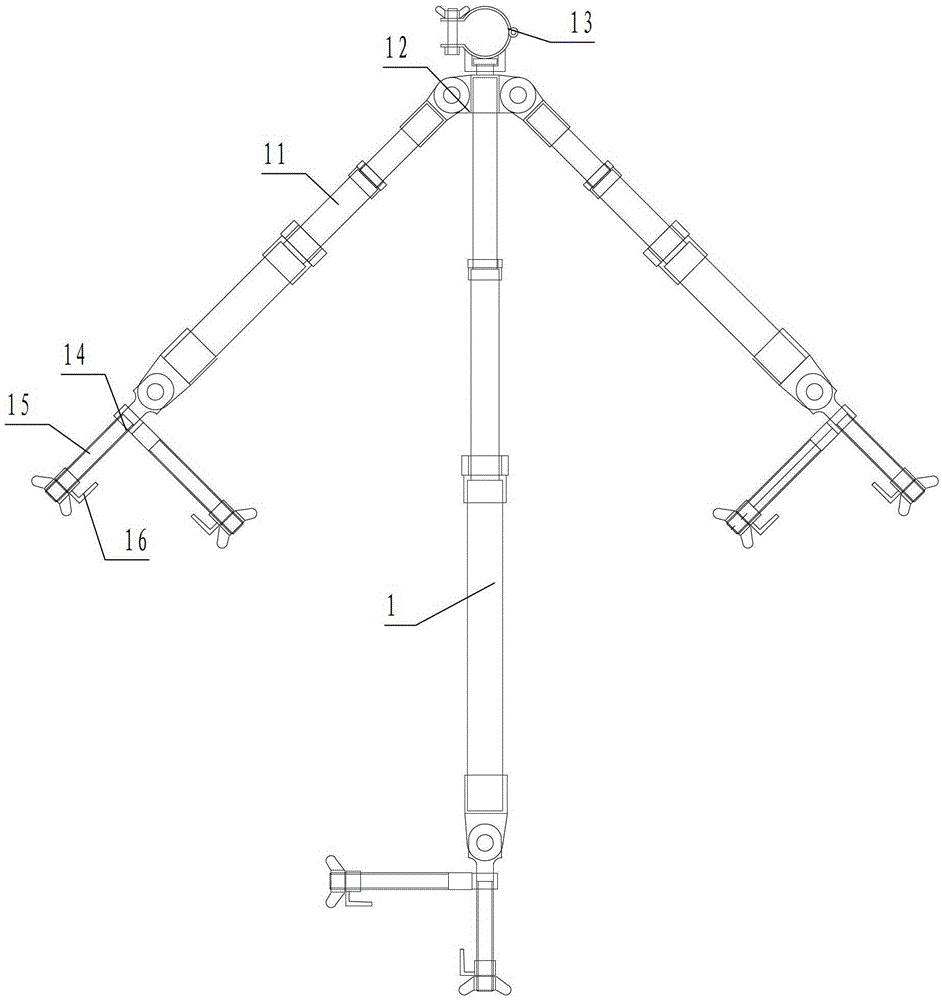

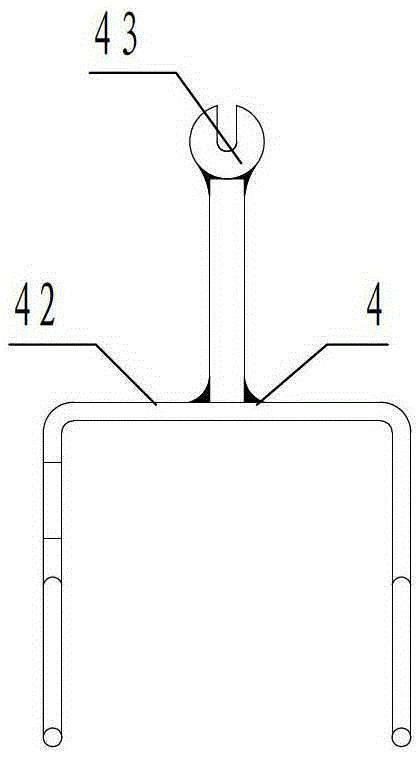

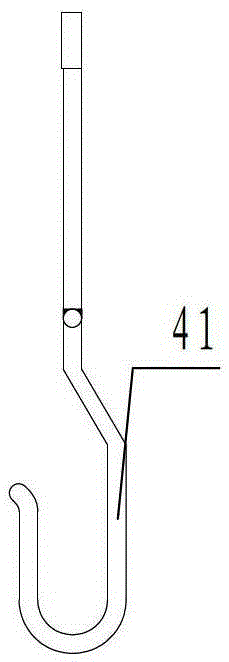

[0042]A method for replacing an anti-vibration hammer, (1) Assemble the supporting frame 1 for the replacement anti-vibration hammer, the insulating operating rod 3, the electric bolt locking device 2, and the grab hook 4 of the anti-vibration hammer to the tower; The hooks at the ends of the support rods of the anti-vibration hammer bracket are respectively fixed on different tower materials to form a triangular support form and locked; (3) Insert the insulating operating rod into the plug joint of the replacement anti-vibration hammer support frame and lock it. (4) Adjust the triangular length of the support frame for replacing the anti-vibration hammer, extend the plug joint of the support frame for replacing the anti-vibration hammer to the outside of the cross arm, and control the operating rod , hook the anti-vibration hammer hook to the anti-vibration hammer; (5) The operator selects the angle of the rotating sleeve of the electric bolt locking device according to the on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com