Horizontal linear vibration motor

A vibration motor and horizontal linear technology, which is applied in the direction of electrical components, electromechanical devices, etc., can solve the problems affecting the vibration intensity of linear vibration motors, and it is difficult to realize the miniaturization of the thickness of linear vibration motors, and achieve the effect of thin motor thickness and strong vibration intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

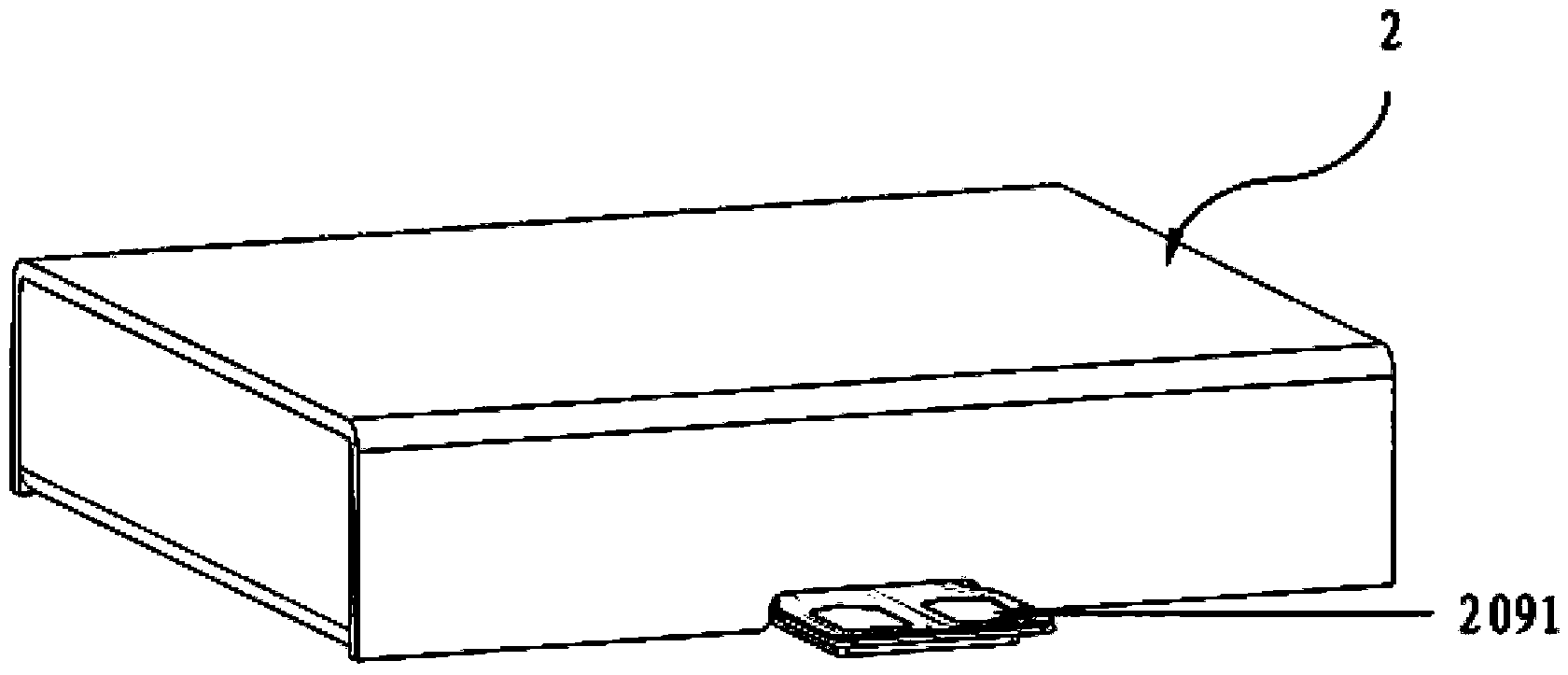

[0037] figure 2 It is the three-dimensional figure of the appearance of the horizontal linear vibration motor according to the present invention. Such as figure 2 As shown, a horizontal linear vibration motor 2 is characterized in that the horizontal linear vibration motor 2 is a six-sided cuboid with predetermined length, width and thickness, and its length direction is the horizontal vibration direction, thereby ensuring that the vibration assembly 201 is horizontal There is enough vibration amplitude space in the direction, and there is a space of predetermined size inside, and an external terminal 2091 for connecting with an external circuit is arranged on the outside. SMT method, etc.

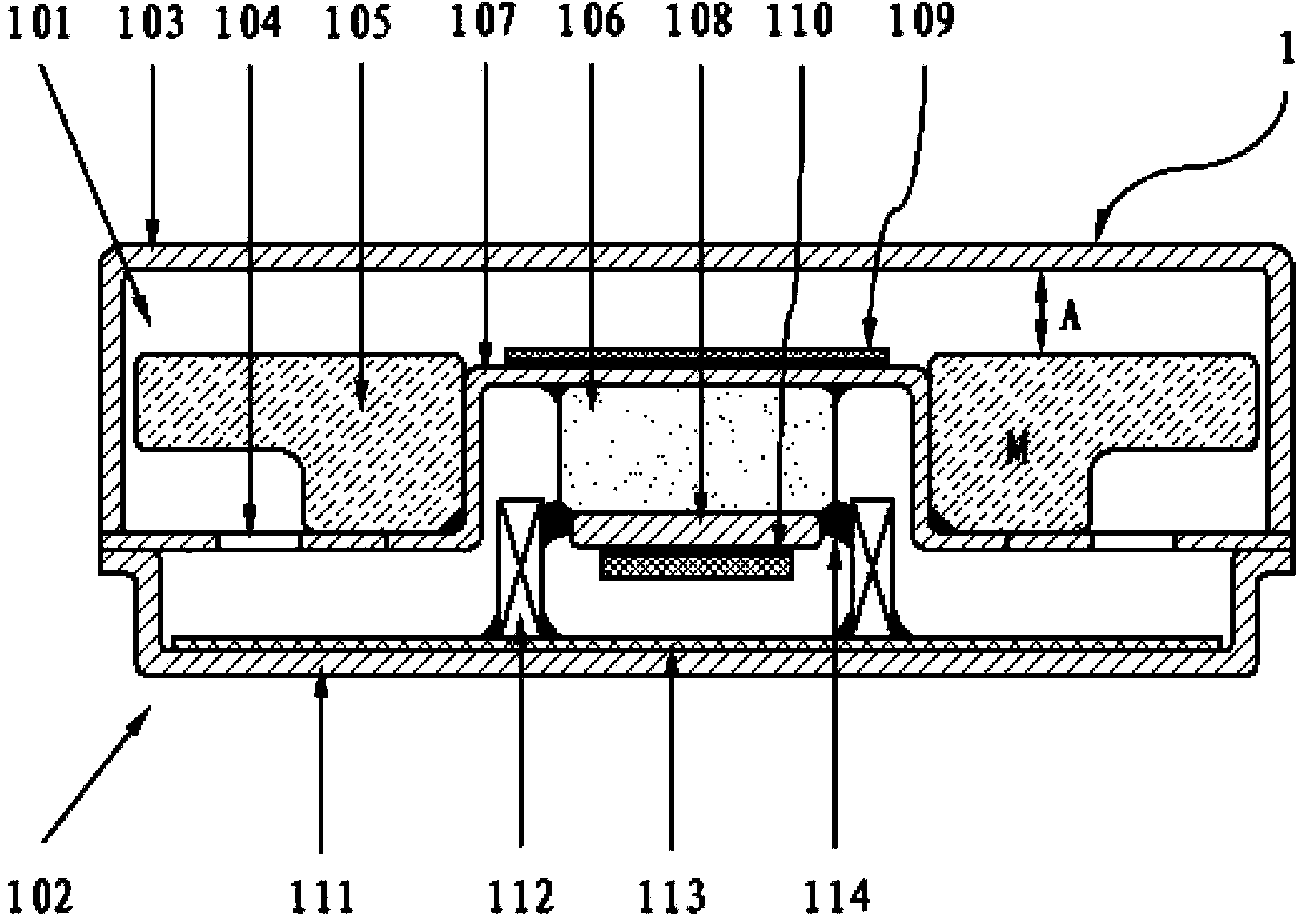

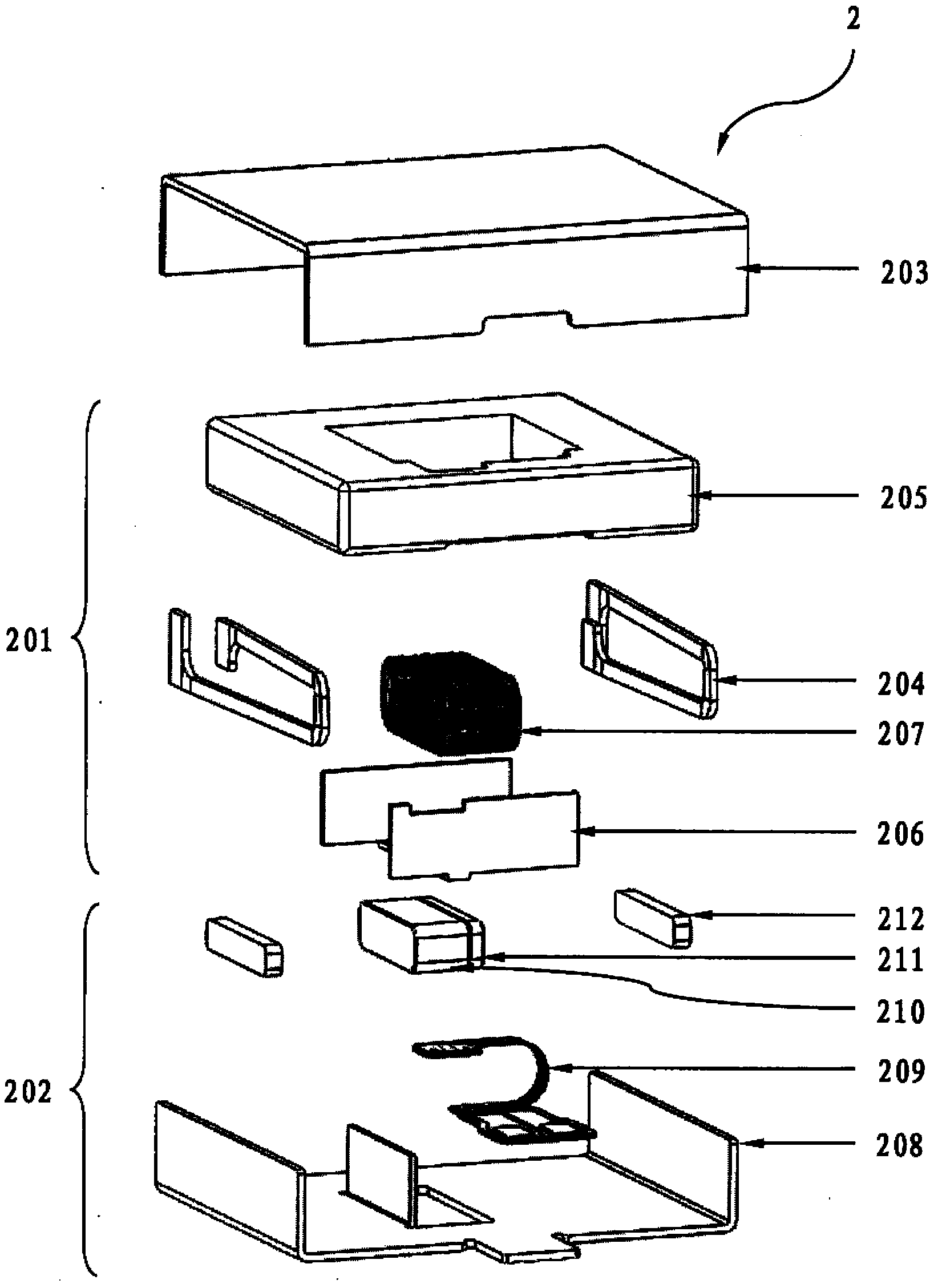

[0038] image 3 is an exploded three-dimensional diagram of the horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com