Direct current side circuit of IGCT (integrated gate commutated thyristor) converter/test circuit and method for designing parameters of clamp capacitor and clamp resistor of direct current side circuit

A technology for testing circuits and clamping capacitors, applied in the field of power electronics, can solve the problems of not being able to obtain optimal performance, not giving clamping circuit design guidelines, and not proposing buffering and clamping circuit design methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing.

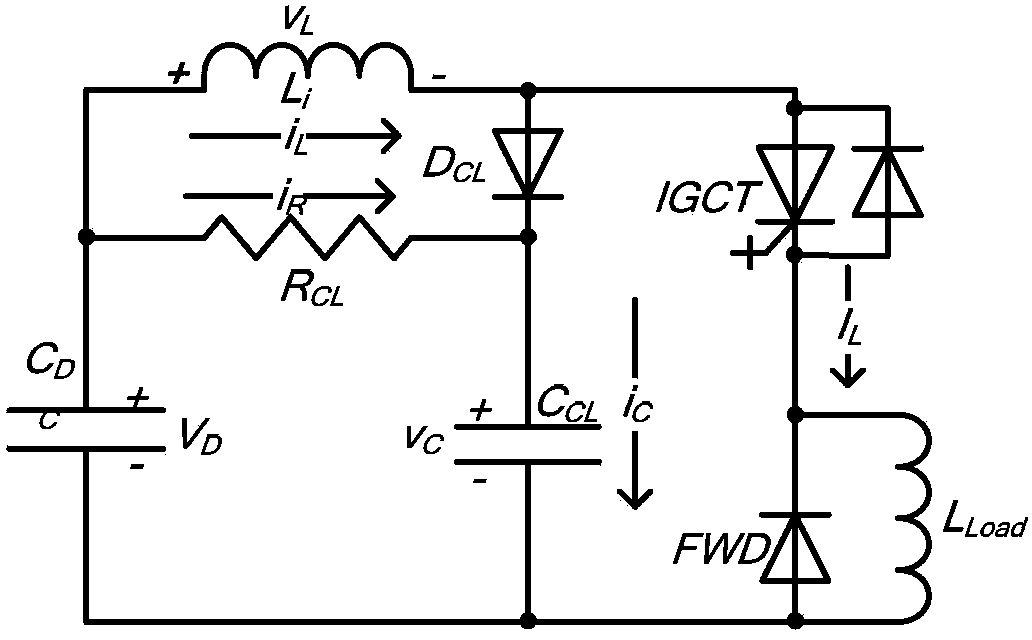

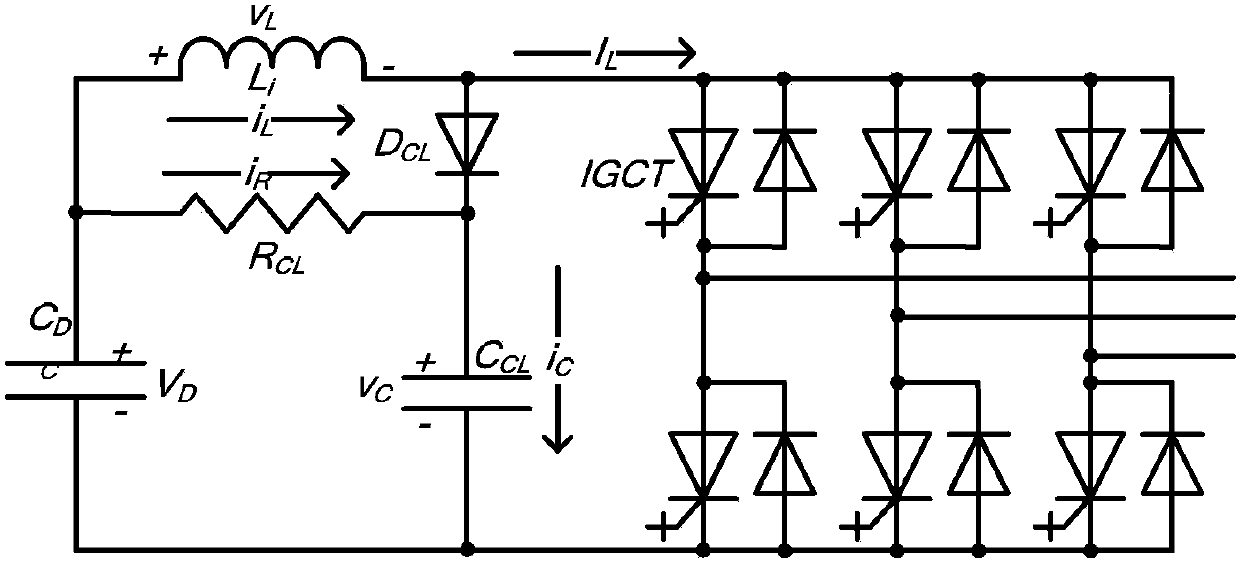

[0040] see Figure 1 to Figure 3 As shown, the IGCT converter / test circuit includes a DC side circuit and a conversion circuit, and the conversion circuit includes one or more IGCT devices. The DC side circuit includes a DC capacitor C DC , snubber inductance L i , clamping diode D CL , clamp capacitor C CL and clamp resistor R CL ; DC capacitance C DC The positive terminal of the snubber inductor L is connected i One terminal and the clamping resistor R CL One end of the snubber inductance L i The other end of the clamping diode D is connected CL positive terminal, the clamping resistor R CL The other end of the clamping diode D is connected CL Negative, clamping diode D CL The negative terminal of the clamp capacitor C is connectedCL One end of the clamping capacitor C CL Connect the other end of the DC capacitor C DC The negative pole of the conversion circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com