Rotary type step-by-step balancer and preparation technology thereof

An equalizer and rotary technology, which is applied in the direction of gearbox control/balance, line transmission parts, cable transmission adaptation, etc., can solve the problems of not being able to produce in large quantities, low processing efficiency, and many parts, and achieve convenient on-site debugging. Easy processing, full-featured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art.

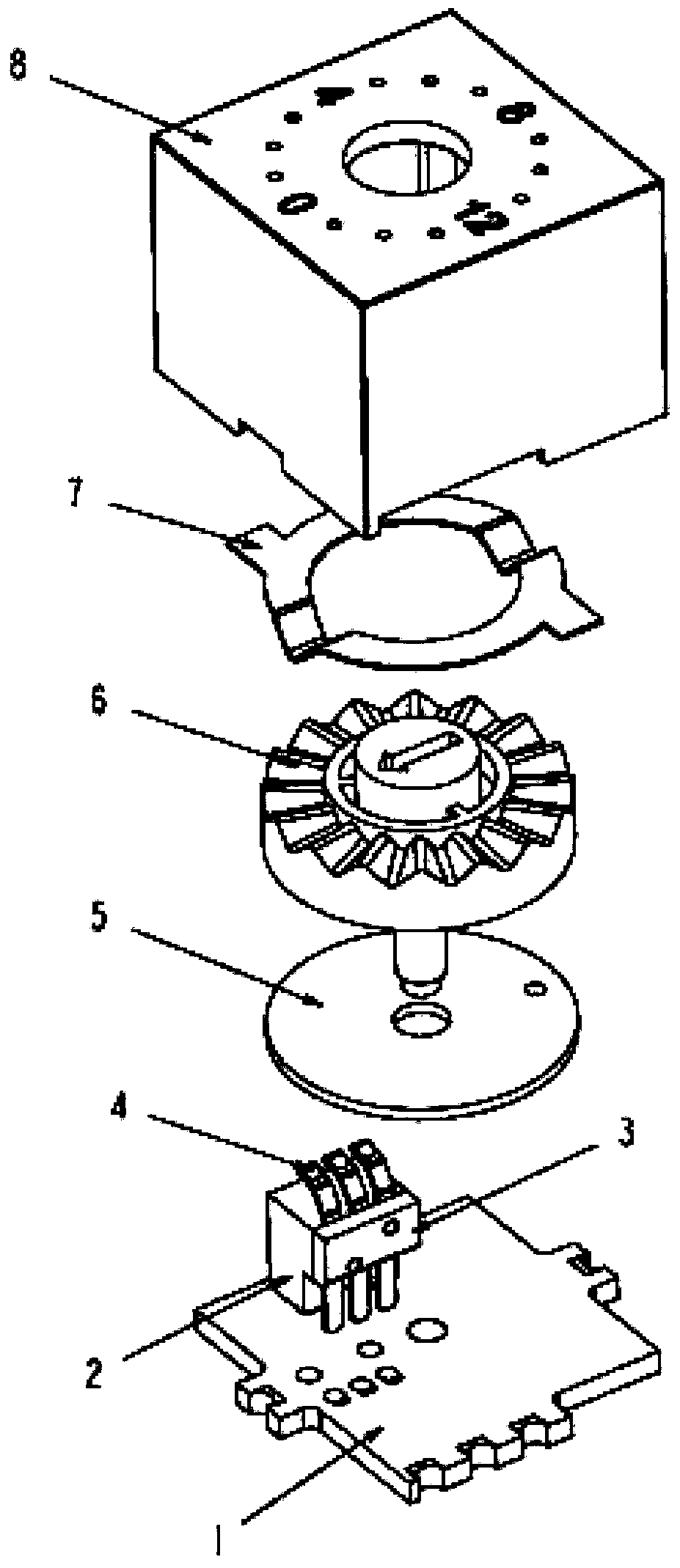

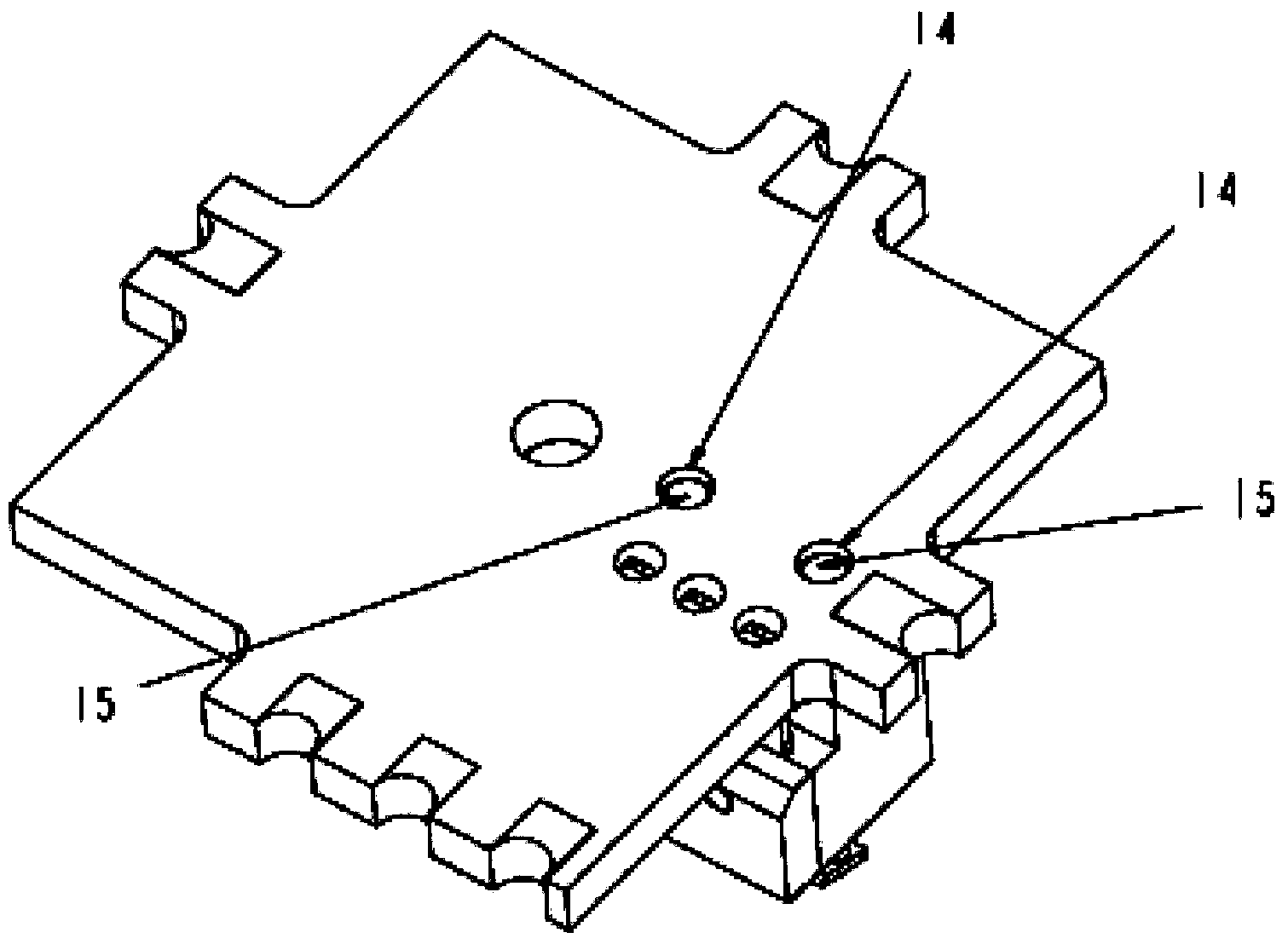

[0033] figure 1 It is the overall structure diagram of the product of the present invention, including the bottom printed board, three-reed connector assembly, cover plate, reed, upper rotating printed board, end gear with shaft, end face positioning reed and housing bushing, when rotating When the handle is used, the positioning cooperation between the end face positioning reed 7 and the shaft end gear 6 can make the shaft end gear 6 produce a precise circumferential shift function;

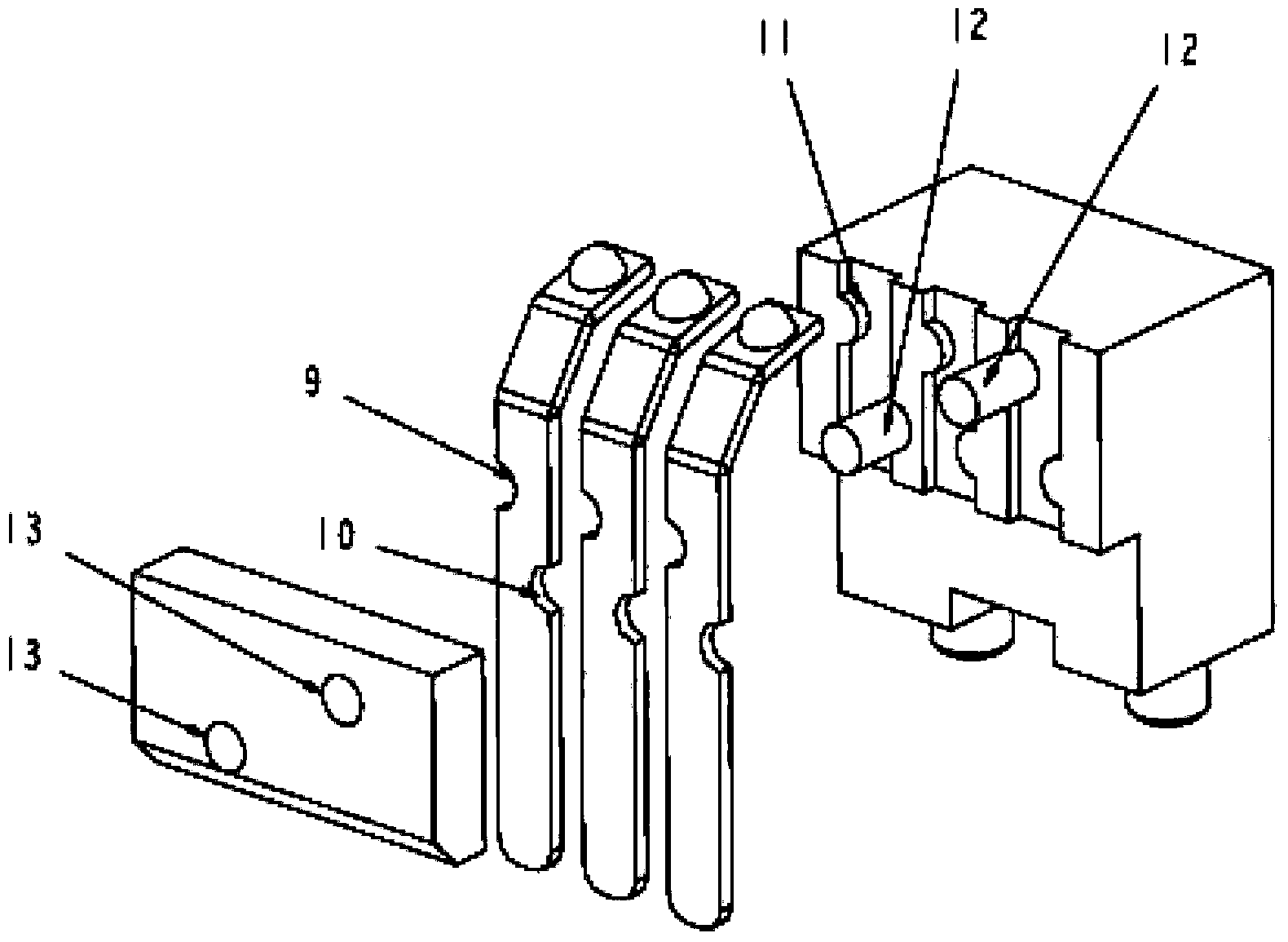

[0034] figure 2 It is an assembly diagram of the three-reed connector assembly in the present invention, relying on the positioning holes 9 and 10 in the reed 4 and the positioning shafts 11 and 12 on the connector seat 2 to precisely match respectively, the precise positioning of the reed can be guar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com