Method for producing interior parts in a foaming tool

A technology for interior parts and tools, which is applied in the field of producing interior parts in foaming tools, can solve problems such as time waste, increased scrap rate, and tool wear, and achieve reduced risk of injury, reduced production costs, and reduced scrap The effect of rate reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

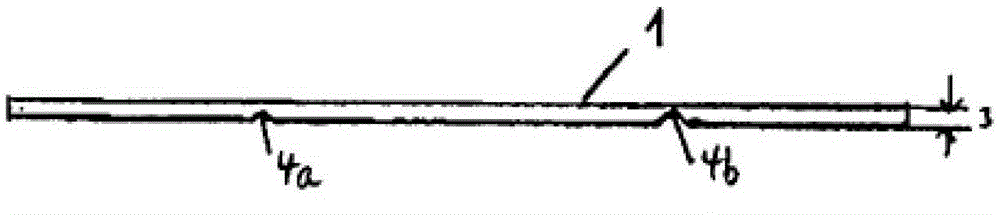

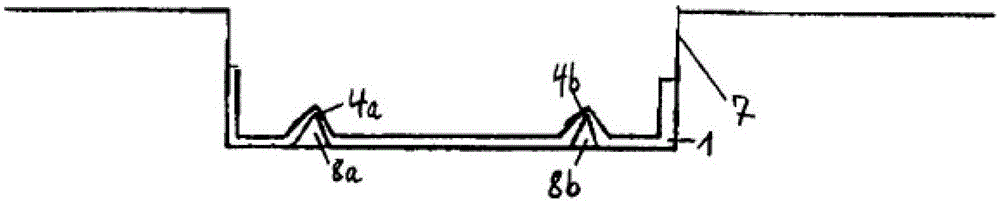

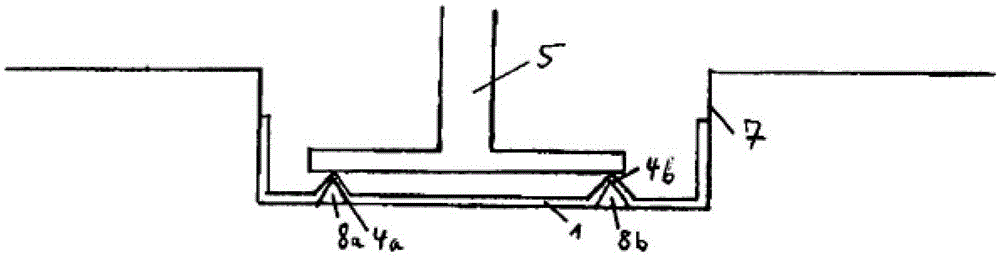

[0026] figure 1 A cross-section of the molded skin 1 into which pre-weakening has been introduced is shown. The molded skin 1 is elastic and can be produced by the rotational sintering method or the slush molding method, but it can also be cast, deep-drawn or sprayed. The molded skin 1 in this embodiment consists of polyvinyl chloride or other thermoforming material, or comprises one of these materials. The thickness of the molded skin 1 in this embodiment is 1.2 mm. The grooves 4a and 4b are V-shaped in this embodiment, but may be of other shapes, such as rectangular or semicircular. The grooves 4a and 4b are spatially separated from each other and not connected to each other; however, the molded skin 1 can also have a through groove. The pre-weakening, i.e. the remaining thickness of the molded skin 1 at the grooves 4a and 4b, is in this embodiment identical, i.e. between 0.4 mm and 0.6 mm depending on the manufacturing method used; however, these Grooves can also have ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com