Liquid crystal display device

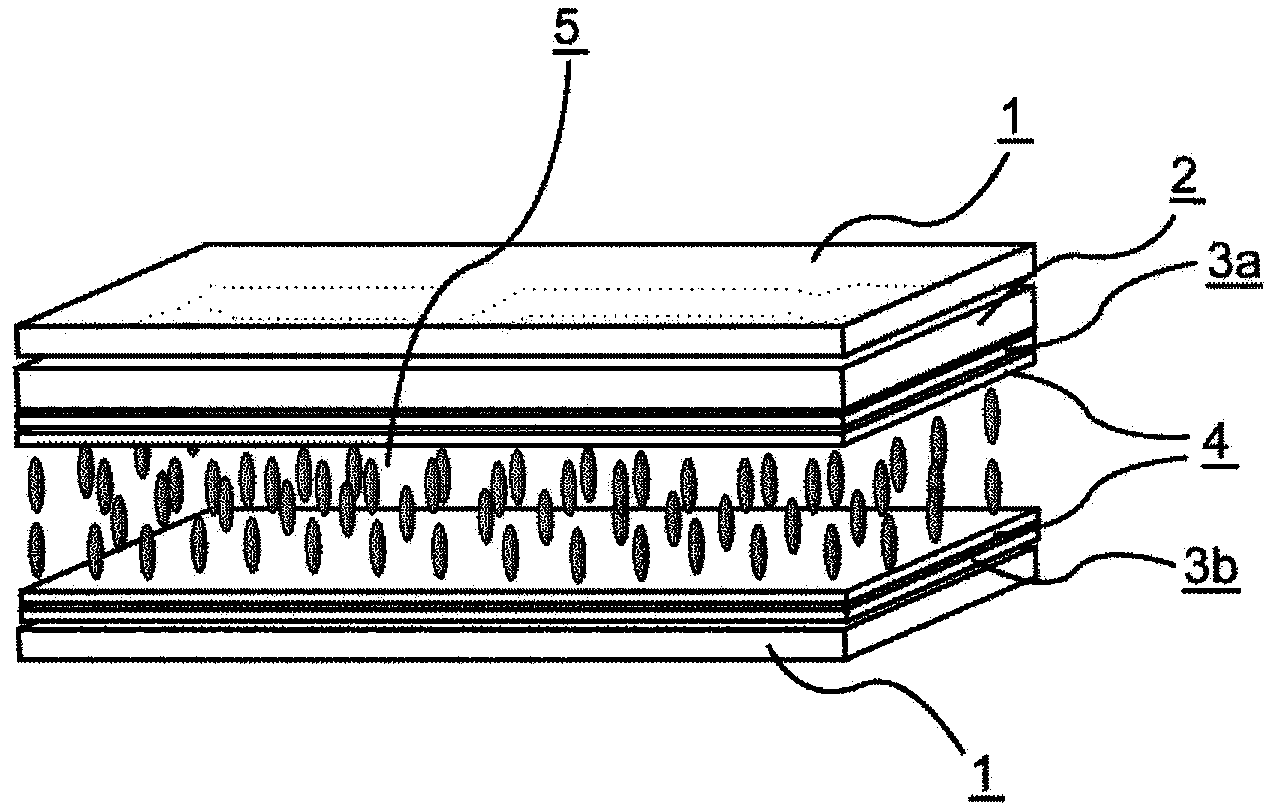

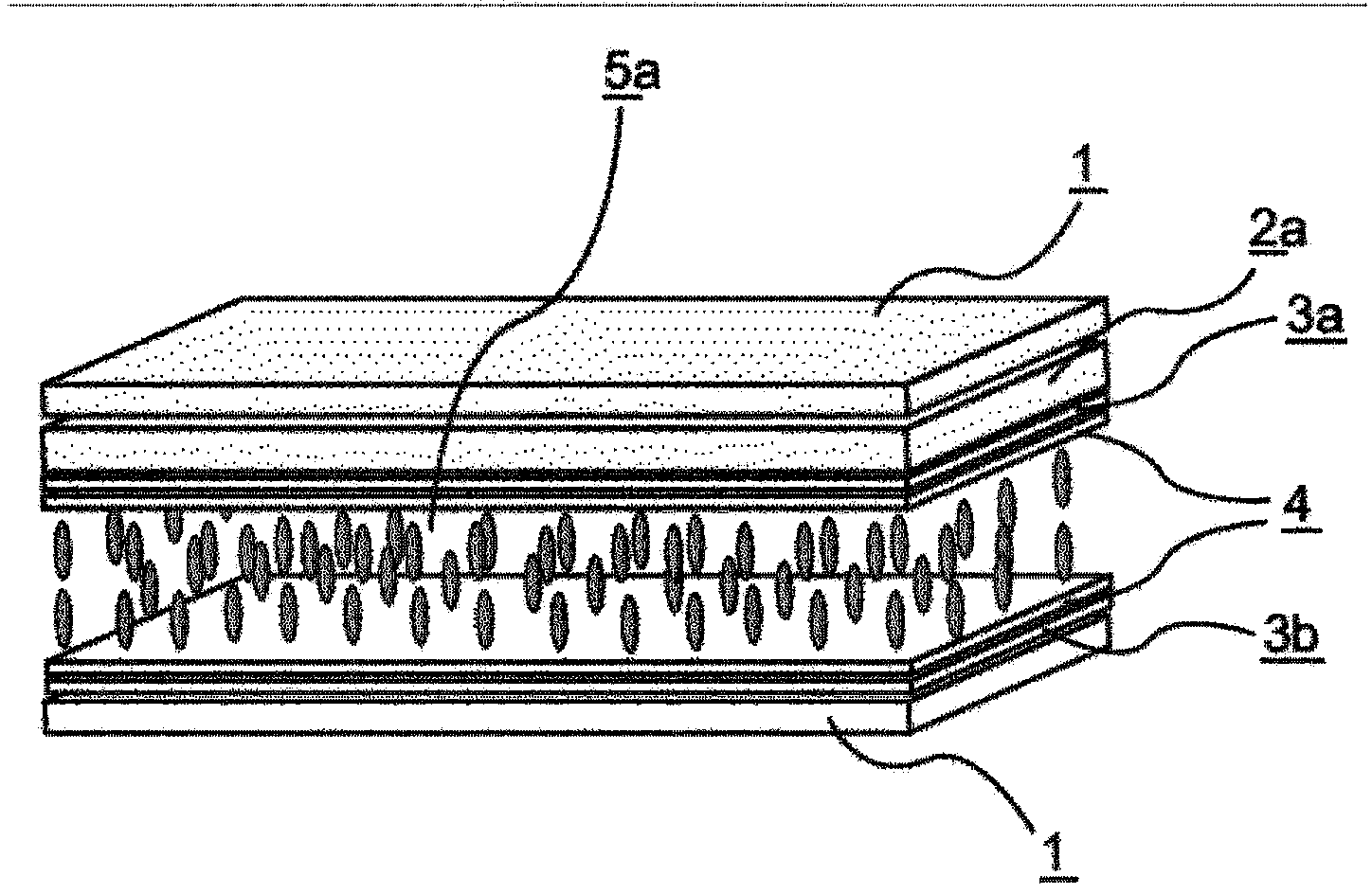

一种液晶显示装置、液晶组合物层的技术,应用在液晶材料、光学、仪器等方向,能够解决电压保持率增加、取向不均、烧屏显示不良等问题,达到防止降低、防止白斑的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4)

[0260] The first and second substrates are made into electrode structures, and vertical alignment films are formed on the opposite sides of each, and then subjected to weak rubbing treatment to form a VA unit. The first and second substrates are sandwiched between the table 2 The liquid crystal composition 1 with negative dielectric anisotropy is shown. Next, the color filters 1 to 4 shown in Table 1 were used to make a liquid crystal display device of Example 1 (d gap =3.5μm, oriented film SE-5300). The VHR and ID of the obtained liquid crystal display device were measured. In addition, the burn-in evaluation of the obtained liquid crystal display device was performed. The results are shown in Table 3.

[0261] [Table 2]

[0262]

[0263] [table 3]

[0264]

[0265] The liquid crystal display devices of Examples 1 to 4 can realize high VHR and small ID. In addition, there is no afterimage in the burn-in evaluation, or even if there is, it is a very small allowable level.

Embodiment 5~12)

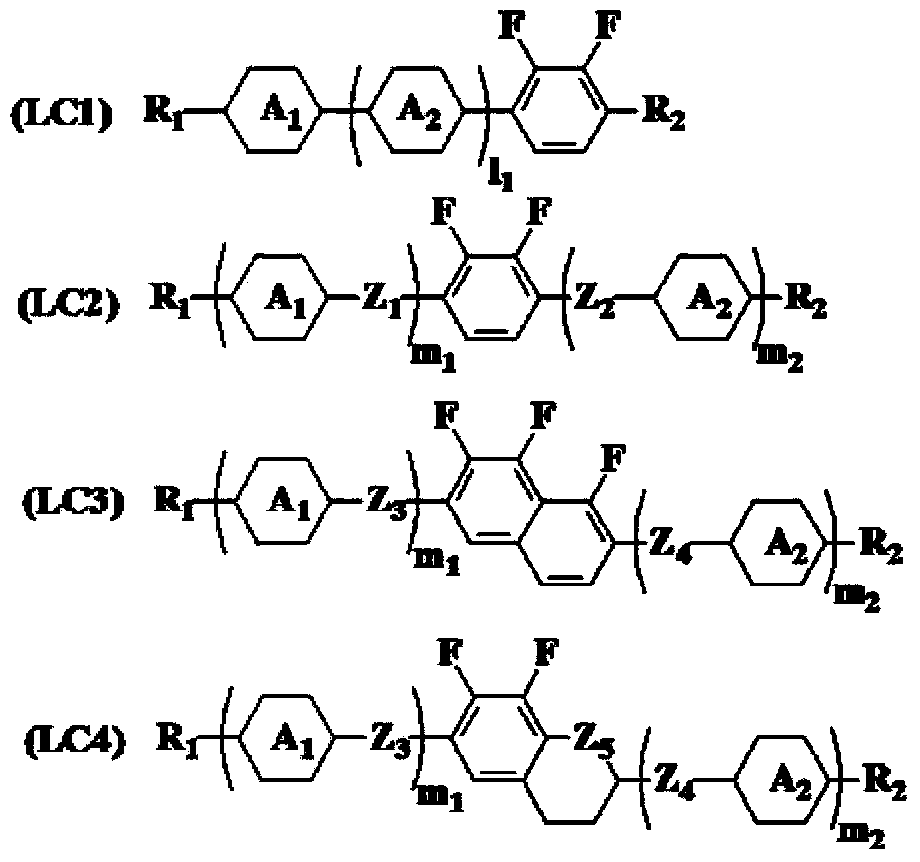

[0288] The negative dielectric anisotropic liquid crystals shown in Table 10 were sandwiched in the same manner as in Example 1, and the color filters shown in Table 1 were used to prepare liquid crystal display devices of Examples 5 to 12, and the VHR and ID were measured. In addition, the burn-in evaluation of the liquid crystal display device was performed. The results are shown in Tables 11 and 12.

[0289] [Table 10]

[0290]

[0291] [Table 11]

[0292]

[0293] [Table 12]

[0294]

[0295] The liquid crystal display devices of Examples 5 to 12 can realize high VHR and small ID. In addition, there is no residual image in the burn-in evaluation, or even if there is a very small allowable level.

Embodiment 13~28

[0297] In the same manner as in Example 1, the negative dielectric anisotropic liquid crystals shown in Table 13 were sandwiched, and the color filters shown in Table 1 were used to prepare liquid crystal display devices of Examples 13 to 28, and the VHR and ID were measured. In addition, the burn-in evaluation of the liquid crystal display device was performed. The results are shown in Tables 14-17.

[0298] [Table 13]

[0299]

[0300] [Table 14]

[0301]

[0302] [Table 15]

[0303]

[0304] [Table 16]

[0305]

[0306] [Table 17]

[0307]

[0308] The liquid crystal display devices of Examples 13 to 28 can achieve high VHR and small ID. In addition, there is no residual image in the burn-in evaluation, or even if there is a very small allowable level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com