Soil turning and stubble burying machine

A technology for turning soil and shoveling soil, which is applied to harvesters, soil preparation machines, crop processors, etc., can solve the problems of high power consumption of rotary tillage, no application of rice and wheat straw, and affecting the growth of subsequent rice.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

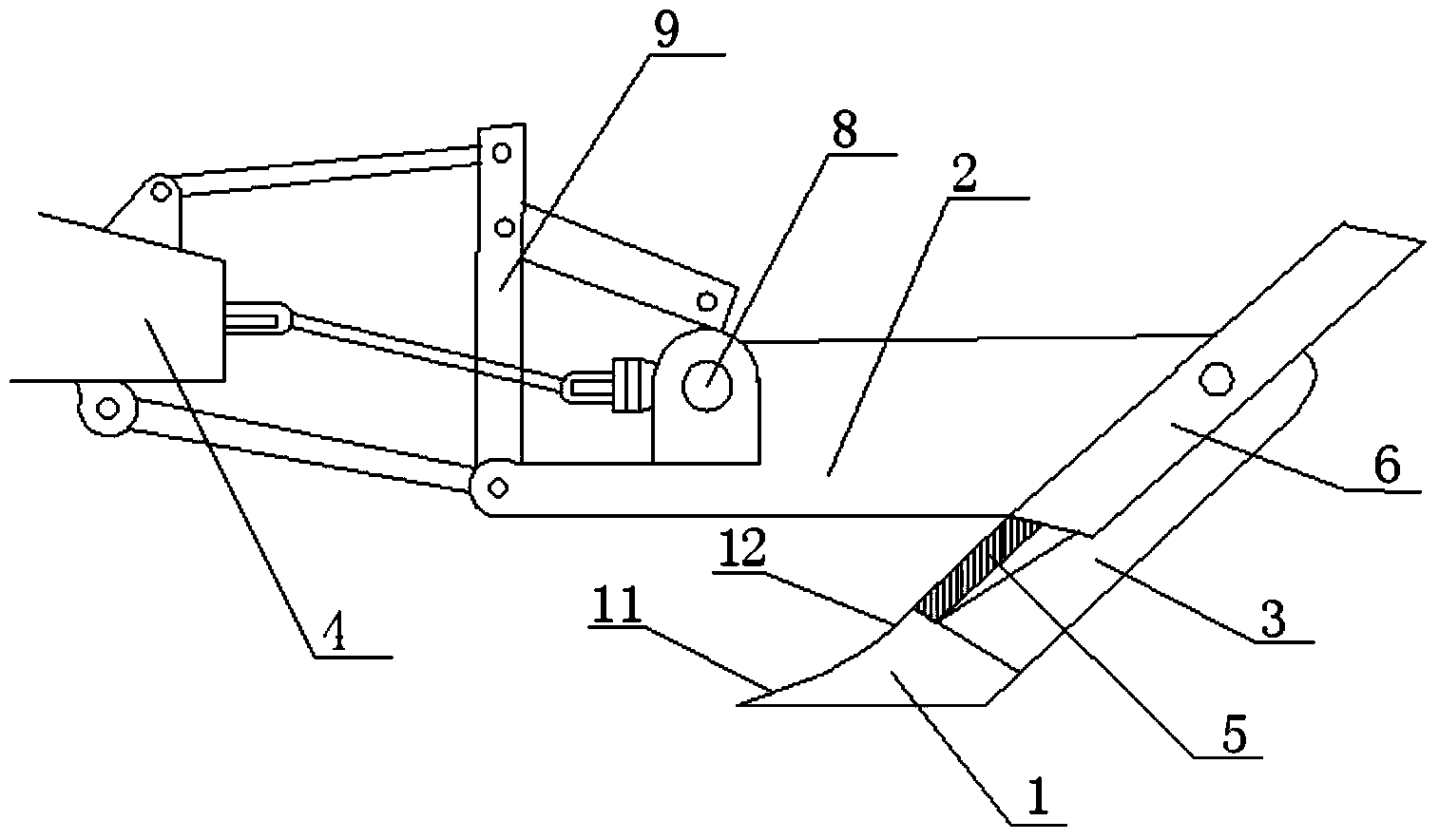

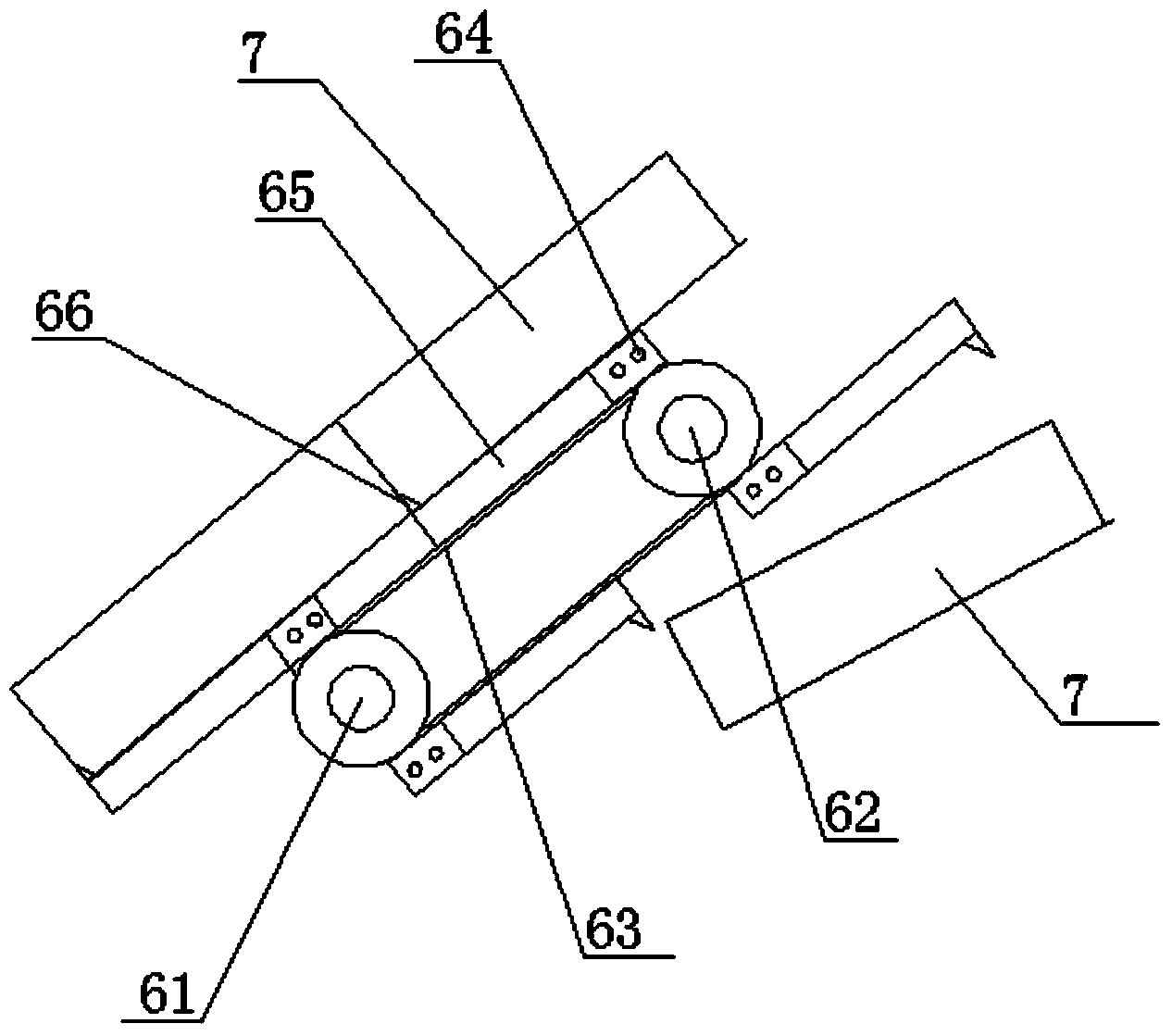

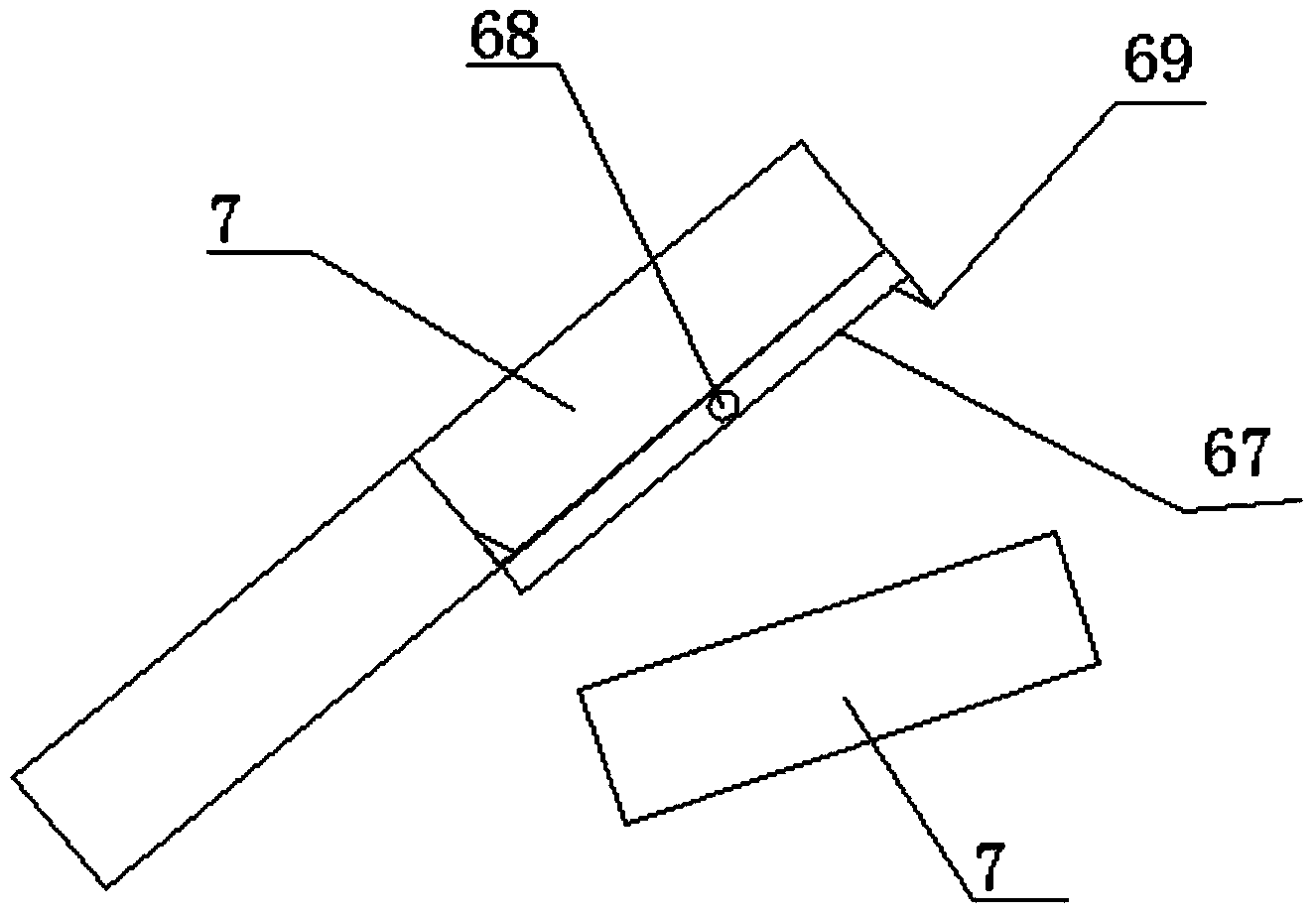

[0036] Such as figure 1 , figure 2 and image 3Shown, a kind of stubble turning machine is characterized in that: taking the direction of use as a reference, it includes at least one soil blade 1 arranged horizontally with a certain width and a traction frame 2 arranged above the soil blade, each Both sides of each soil shovel are respectively fixedly connected with a connection seat 3, and the connection seat is fixed on the traction frame; the front end of the traction frame is connected with the external traction device 4, and the oblique rear of the shovel The top is provided with a soil guide plate 5 and a tiller 6 in turn, and the external traction device can drive the traction frame to move horizontally, and drive the shovel knife to scoop up the plow layer soil, so that the scooped up plow layer soil 7 along the The soil guide plate is transported to the tiller; the traction frame is provided with a transmission mechanism 8, and the transmission mechanism can output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com