Daochi powder formula granule as well as preparation method, use and detection method thereof

A technology of formula granules and Daochi powder, applied in the field of Daochi powder formula granules and their preparation, can solve the problems of changes in pharmacological action, non-equivalence, changes in clinical efficacy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

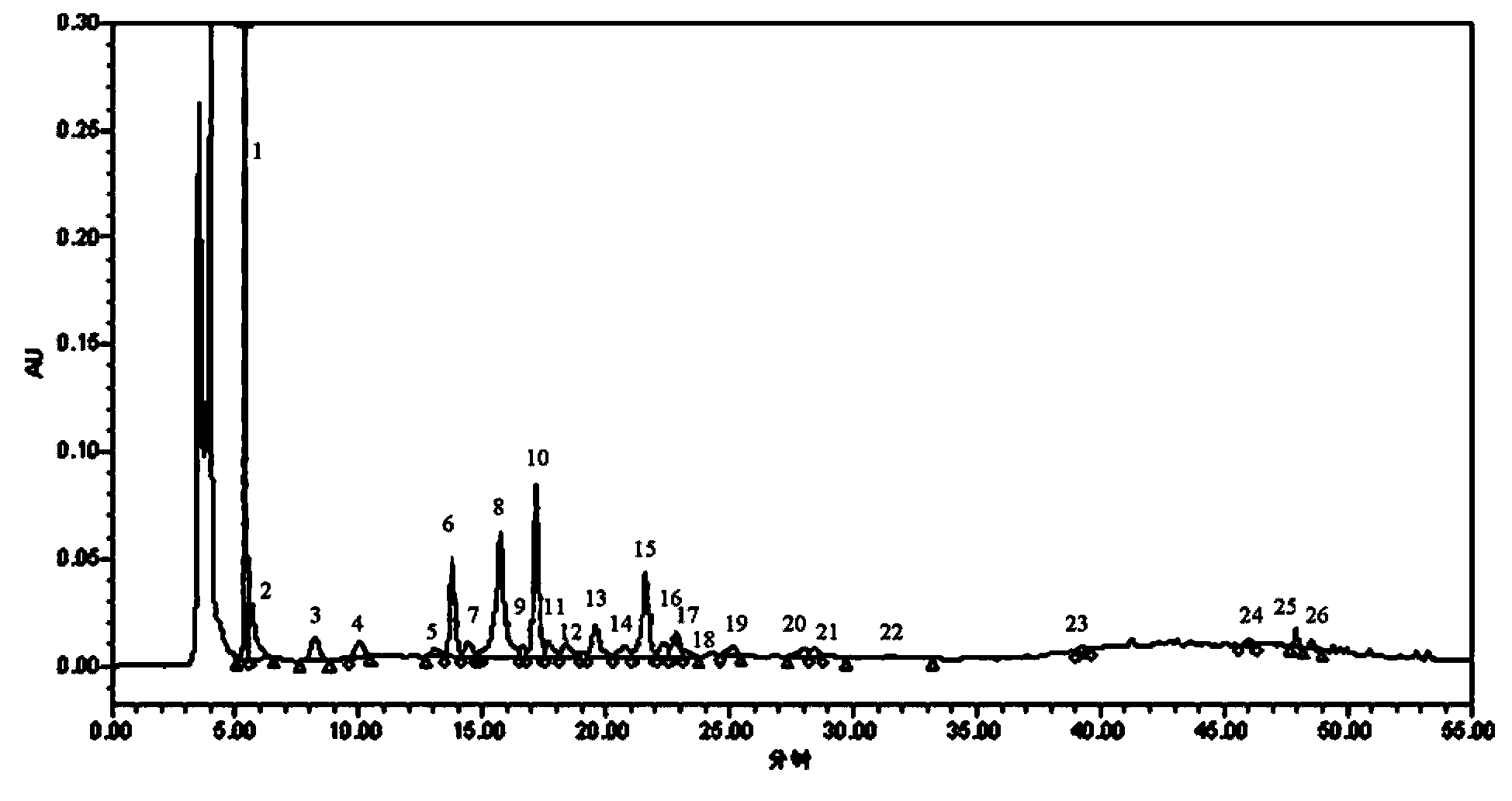

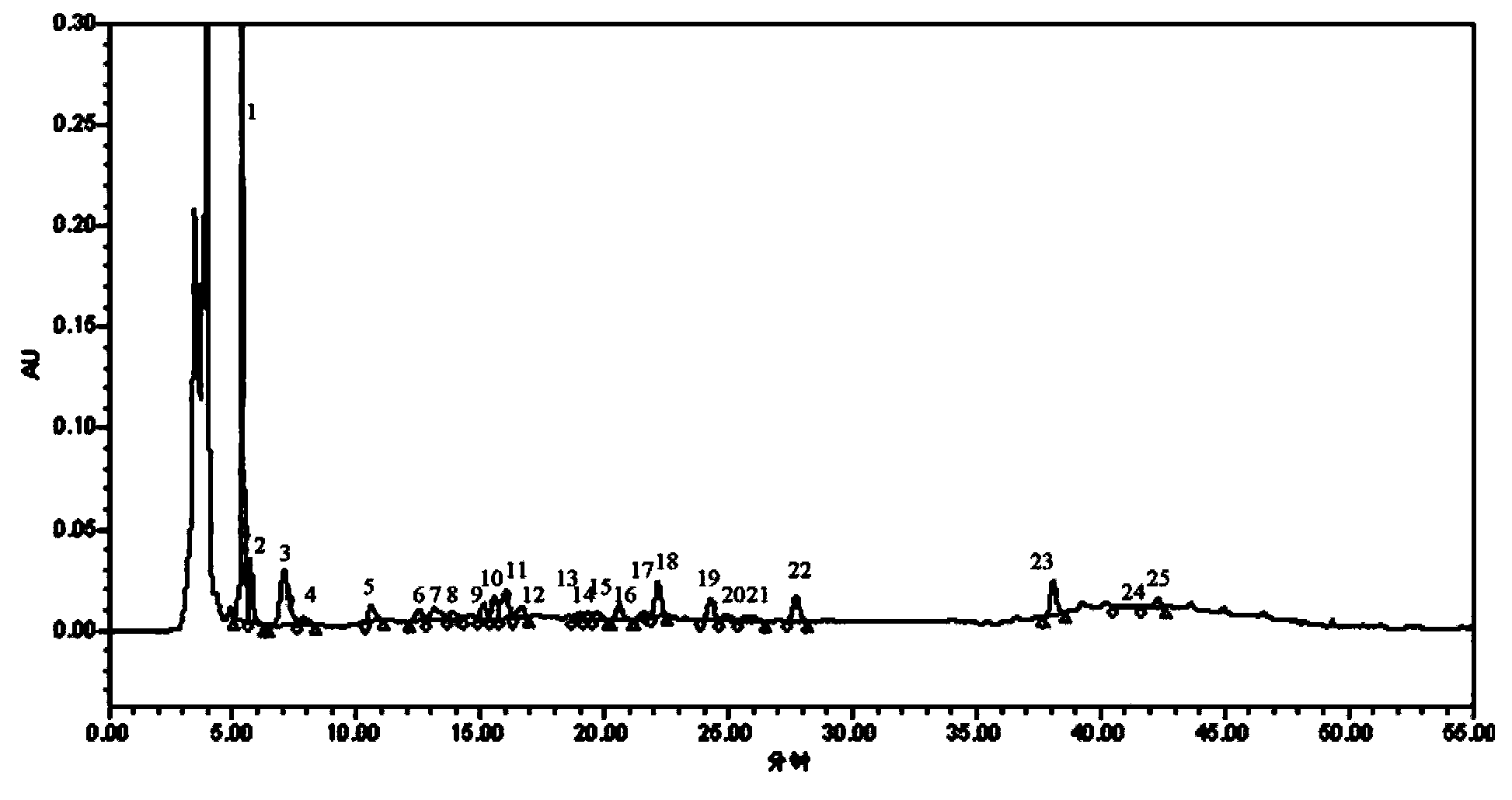

[0088] Example 1 Selection of preparation process of Daochisan formula granules

[0089] Preparation:

[0090] Take the raw rehmannia, wood tongs, bamboo leaves and raw licorice with a mass ratio of 1:1:1:1, soak in water, decoct, filter, combine the filtrate and concentrate it into a clear paste, then dry and granulate.

[0091] 1. The research on the extraction technology of Daochisan formula granules is as follows:

[0092] The influencing factors are: extraction times, extraction time, water addition (unit is L / Kg total amount of medicinal materials). Optimizing the extraction process by orthogonal test, choose L 9 (3 4 ) Orthogonal table, focusing on the above three factors, taking the content of glycyrrhizic acid as the inspection index, and the factor level table is shown in Table 2.

[0093] Table 2

[0094]

[0095] Test method: Weigh 100g of raw rehmannia, 100g of raw licorice, 100g of mutong, and 100g of bamboo leaves according to the prescription ratio, number 1-9, press L ...

Embodiment 2

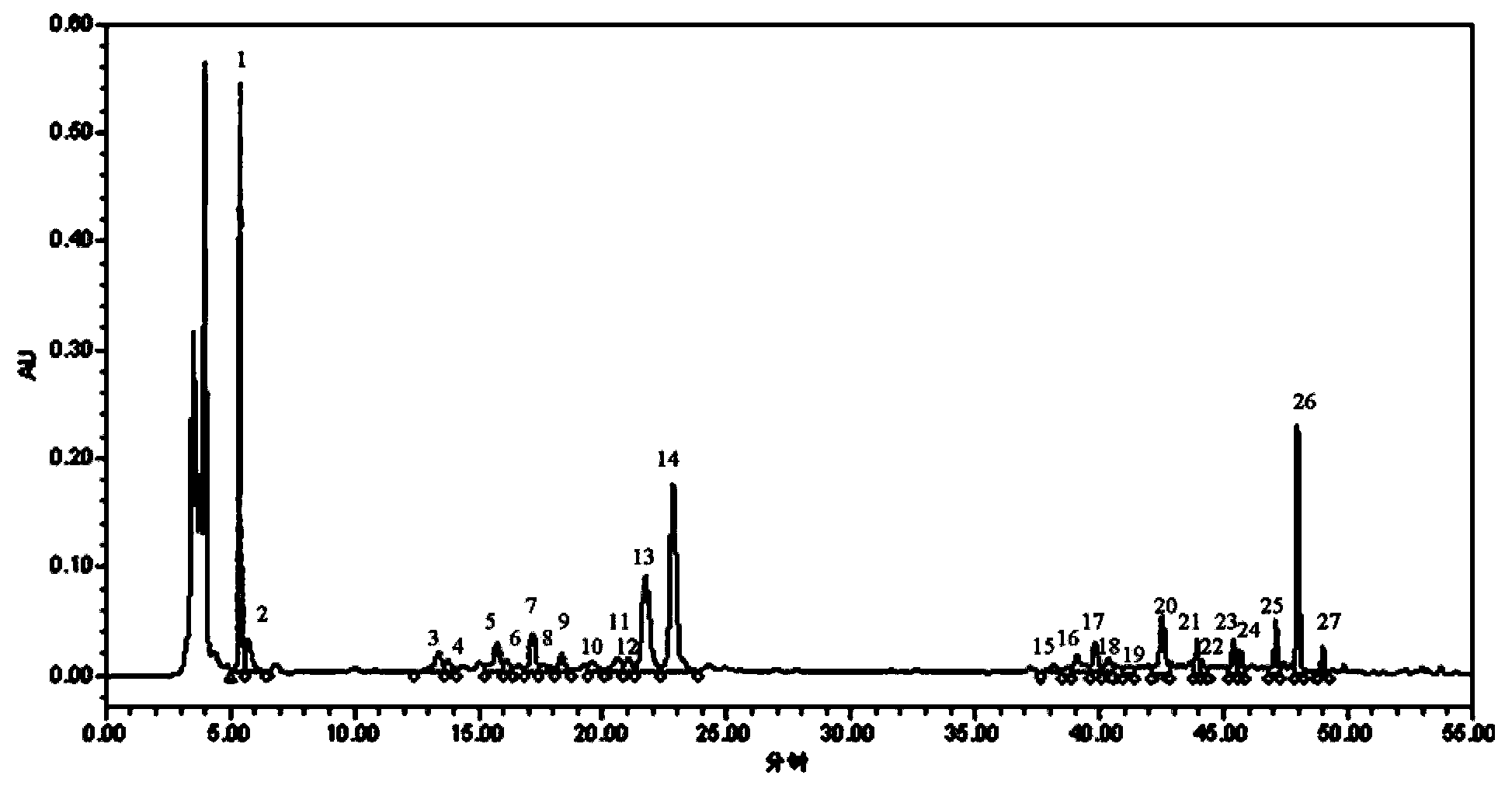

[0106] Example 2 Preparation of Daochisan formula granules

[0107] Take 180.1g of Rehmannia glutinosa, 180.0g of Mutong, 180.0g of bamboo leaves, and 180.2g of licorice, soak in water for 30 minutes, decoct twice, add 10 times the amount of water for the first time, add 8 times the amount of water for the second time, each time Boil for 1.0 hour, filter, combine the two filtrates, concentrate under reduced pressure at 80°C, concentrate to a clear paste with a relative density of 1.05~1.10 (60°C), microwave drying, microwave power 5Kw, material temperature 65°C, drying time: 25min, dry to obtain the extract powder, which is granulated, packed, sieved and tested to obtain the finished product. See the process flow chart figure 1 .

[0108] The dry extract powder results are shown in Table 6.

[0109] Table 6 Extraction result table

[0110]

[0111] Obtained 192.8g of Daochisan formula granule powder.

[0112] See Table 7 for the particle properties of Daochisan formula.

[0113] Tabl...

Embodiment 3

[0116] Example 3 Identification of Daochishan formula granules prepared in Example 2 by thin layer chromatography

[0117] 1. Medicinal materials and reagents

[0118] Licorice reference medicinal material: batch number 120934-200608, purchased from the National Institute for the Control of Pharmaceutical and Biological Products;

[0119] Test product: Daochi powder formula granules (prepared according to the method in Example 2, batch numbers: 12060401, 12060402, 12060403), made by Kangmei Pharmaceutical Co., Ltd.;

[0120] Licorice negative control: take 180.1g of Rehmannia glutinosa, 180.0g of Mutong, and 180.0g of bamboo leaves, which were prepared according to the method of Example 2;

[0121] Thin layer plate: Silicone G plate (made by Kangmei Pharmaceutical Co., Ltd.).

[0122] Reagents are of analytical grade

[0123] 2. Experimental steps

[0124] Identification of licorice in Daochisan formula granules

[0125] Preparation of test solution: Take 2.0g of Daochisan formula partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com