High-moisture chalk vertical mill drying and grinding process

A drying powder and high moisture technology, which is applied in cement production, grain processing, etc., to achieve the effect of saving power consumption, reducing installed power, and expanding the application area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following non-limiting examples illustrate the invention.

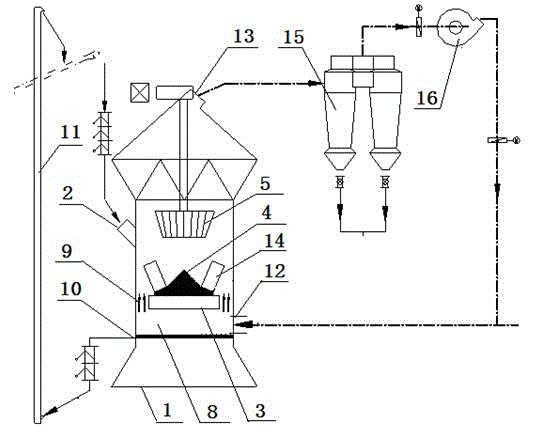

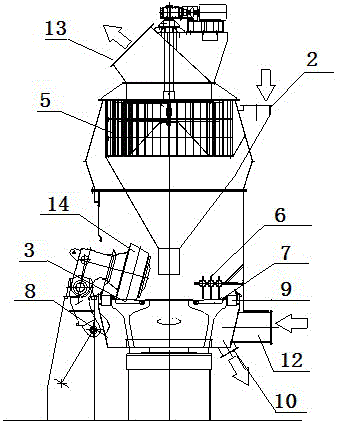

[0025] like figure 1 , 2 As shown, a high-moisture chalk vertical mill drying and grinding process, the viscous chalk with a moisture content of more than 25% is directly put into the vertical mill 1 from the feeding port 2 of the vertical mill 1, and the surface of the material 4 stockpile and the vertical mill The high-temperature gas in 1 conducts rapid heat exchange, and the fine particles whose surface is dried are sent to the powder separator 5 above the grinding disc 3 by the gas in the vertical mill 1 for sorting, and are further dried in the process. After sorting, the qualified finished product enters the finished product collection system, and the water content of the finished material is less than 1%. The large-grained material that has not been dried thoroughly returns to the center of the grinding table 3, and is mixed with the newly fed sticky wet material 4 for further drying and grinding. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com