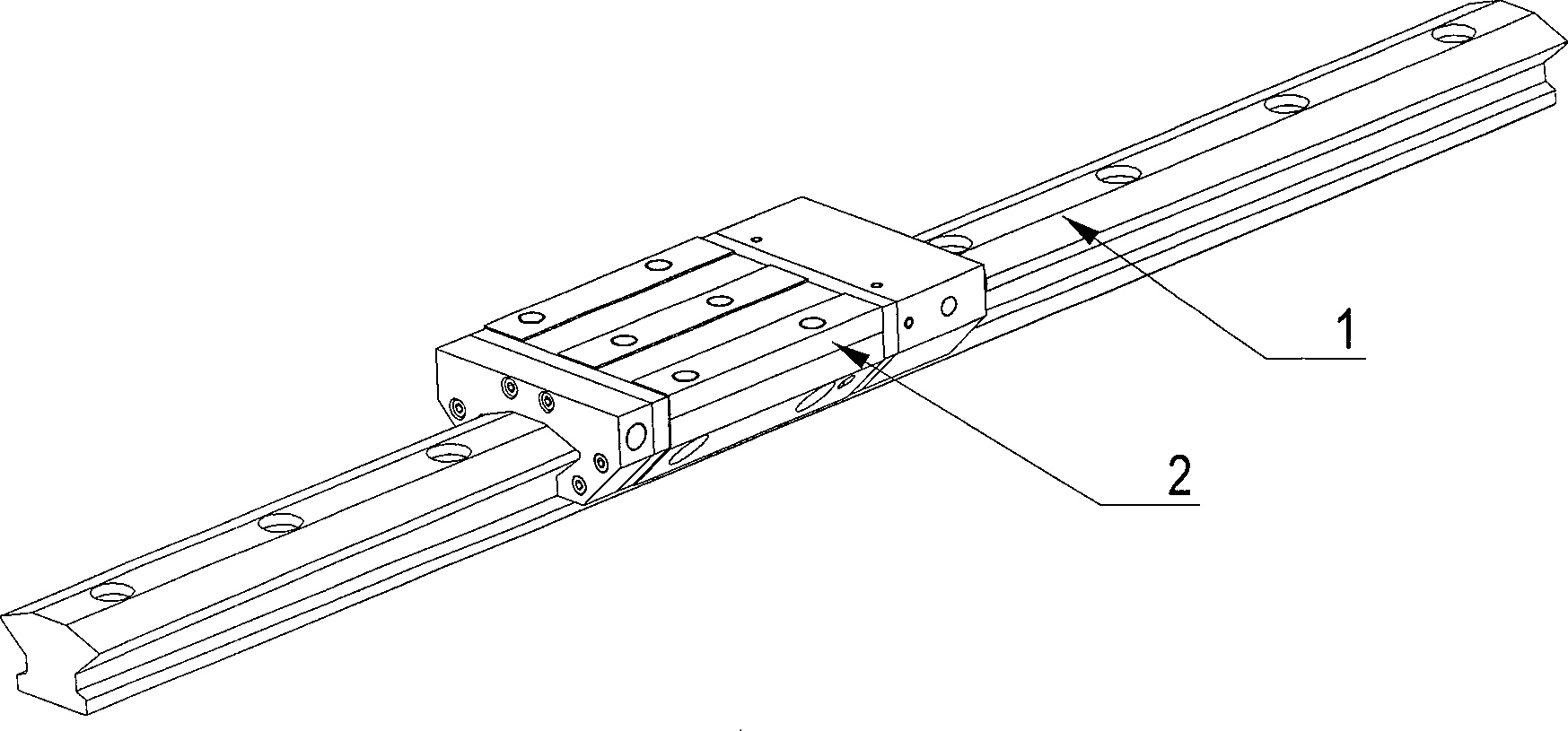

Guide rail and sliding block mechanism of sliding block type hydrostatic guide rail

A hydrostatic guide rail and slider type technology, used in metal processing machinery parts, large fixed members, metal processing equipment, etc., can solve the problems of various structures, affecting the movement accuracy of machine tools, and poor vibration absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiment of the invention will be described in conjunction with the accompanying drawings.

[0013] like figure 1 As shown, the present invention is composed of a guide rail 1 and a slider 2, wherein the hydrostatic slider 2 is as Figure 2-4 As shown, its inner shape is a downward concave groove, and there are two bearing surfaces on the upper and lower sides of the groove wall, and the upper bearing surface is opened with large-area pressure oil chambers 6 and 8, and its horizontal angle is 20°, effectively The bearing capacity of the static pressure guide rail is improved; there are small-area pressure oil chambers 7 and 9 on the lower bearing surface, and the horizontal angle is 40°, which effectively improves the rigidity of the slider.

[0014] The load-bearing surface of the guide rail matches the load-bearing surface of the slider and has a certain gap, and the gaps of the static pressure guide rails of different specifications are different.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com