Rail cleaning device for crane

A crane and track cleaning technology, applied in the direction of track system, transportation and packaging, load hanging components, etc., can solve the problems of burnt motor, wheel derailment, rollover, corrosion of wheel tread, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

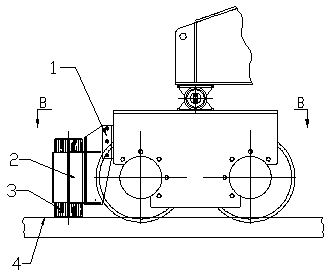

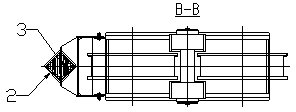

[0011] The crane track clearing device of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0012] As shown in the figure, the crane rail clearing device of the present invention includes a guide tube 2 installed on the front end of the wheel through a mounting frame 1, and a hardwood stopper 3 whose outer diameter matches the inner surface of the guide tube 2 is provided in the guide tube 2. The lower end of stopper 3 freely falls on rail surface 4, and wherein guide pipe 2 cross-sectional shape is curved surface shape structure or water chestnut structure, and specifically guide pipe 2 cross-sectional shape can be square, rhombus, rectangle or circular hole etc., of course hardwood The outer profile of the stopper 3 should be adapted to the inner cavity profile of the guide tube 2, so that the hardwood stopper 3 can slide freely in the guide tube 2, and due to the self-weight of the hardwo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com