Automatic traction system for large-size tower crane mounting and dismounting standard knot and traction method thereof

A technology of tower cranes and traction systems, applied in cranes and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

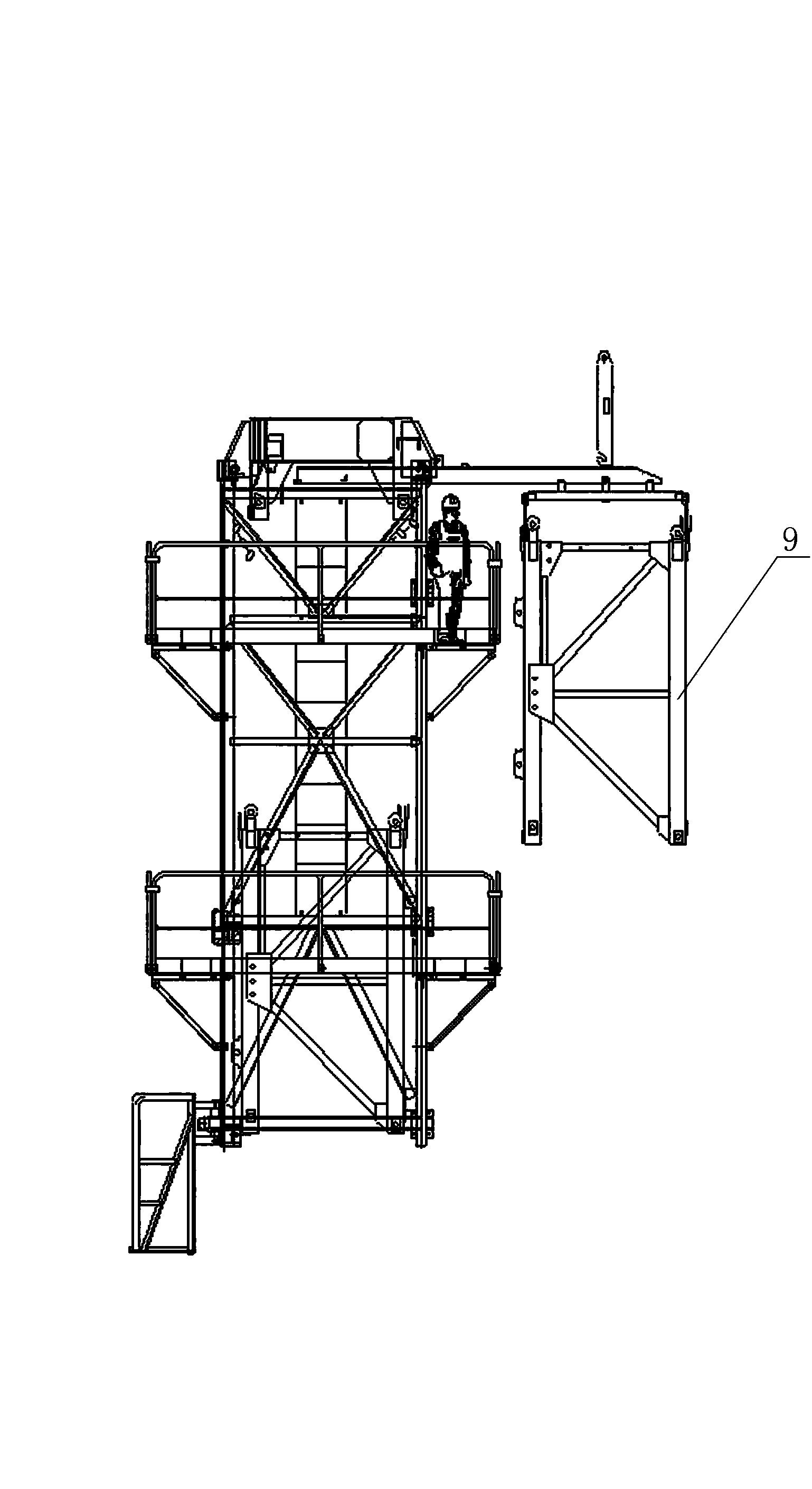

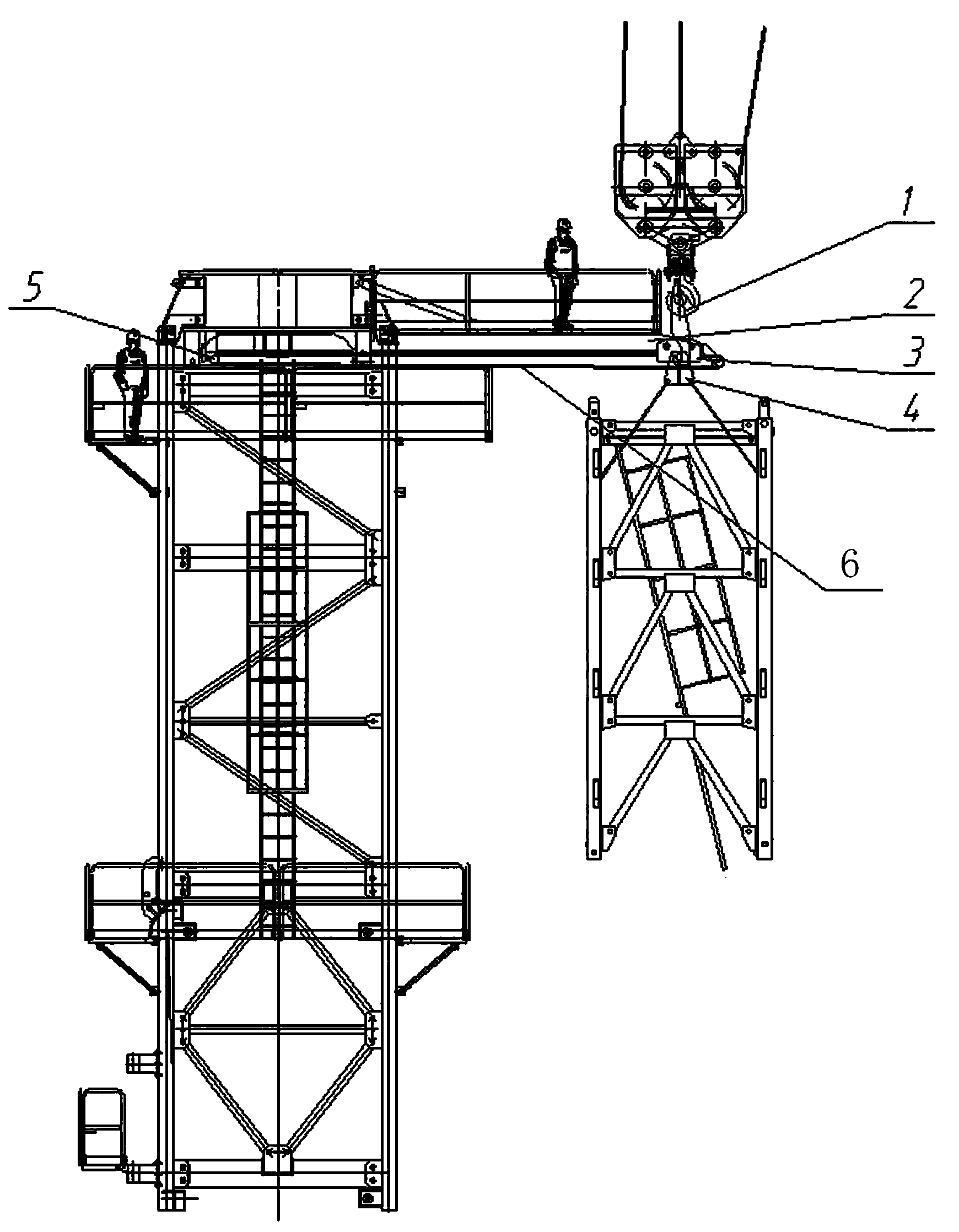

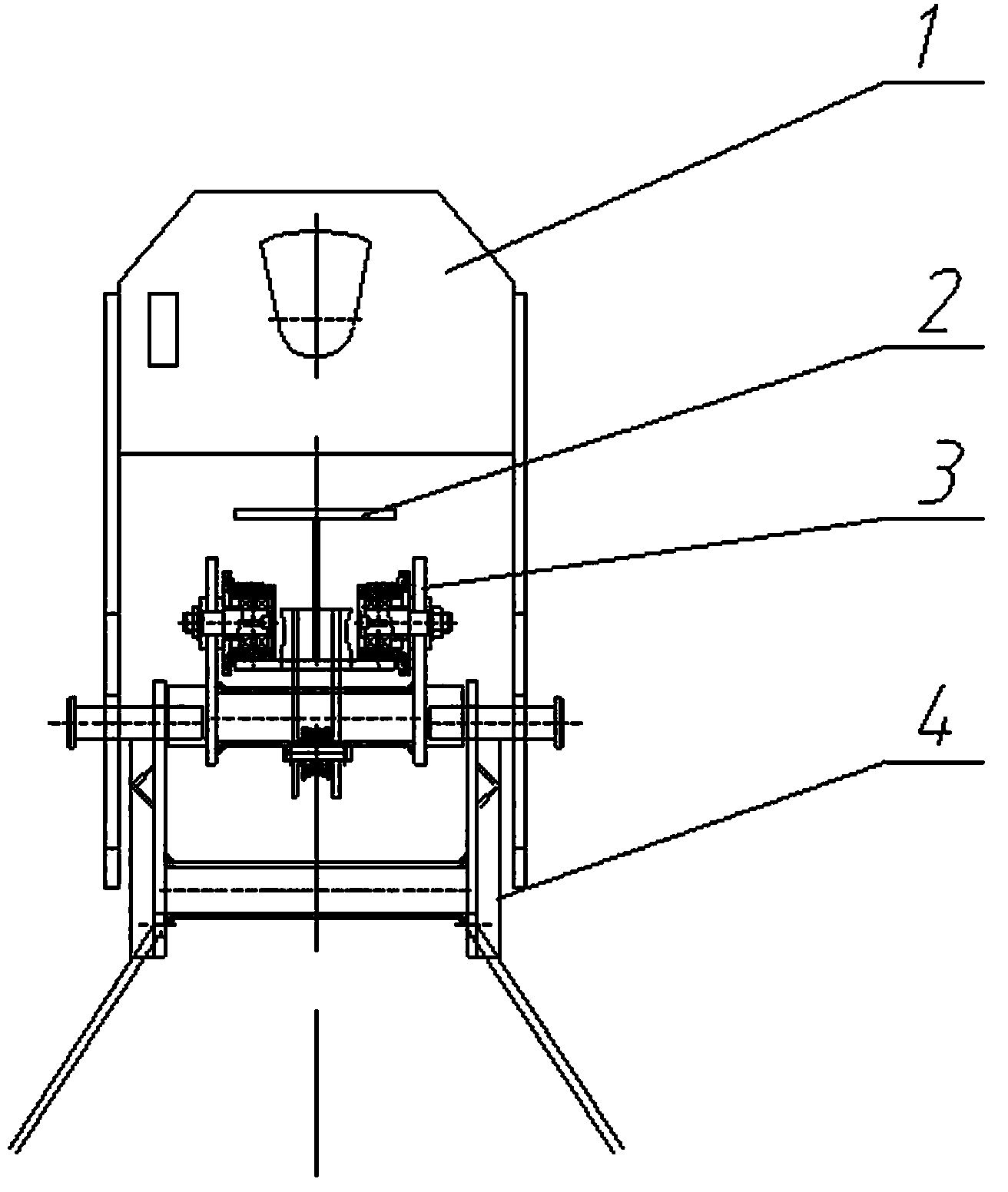

[0020] The invention discloses an automatic traction system for installing and dismantling a standard section of a large tower crane, such as figure 2 As shown in , it mainly includes a monorail introduction beam 2, which is different from the prior art in that: the monorail introduction beam 2 is installed on the lower panel of the lower support, and the monorail introduction beam 2 is equipped with a platform and a railing for the installation and removal personnel to pass through. The tail end of the monorail introduction beam 2 is provided with a traction mechanism 5, and the traction mechanism 5 is threaded with a traction wire rope 6, and the long line 20 of the traction wire rope 6 bypasses the guide pulley 7 at the head end of the monorail introduction beam 2 and then passes the rope with the introduction trolley 3. The card is fixed, the short...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com