Coaxial double-winding-drum self-locking winch

A double-drum and reel technology, applied in hoisting devices, spring mechanisms, etc., can solve problems such as loss of control of the winch, broken ropes, safety accidents, etc., and achieve the effect of improving the safety factor and improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

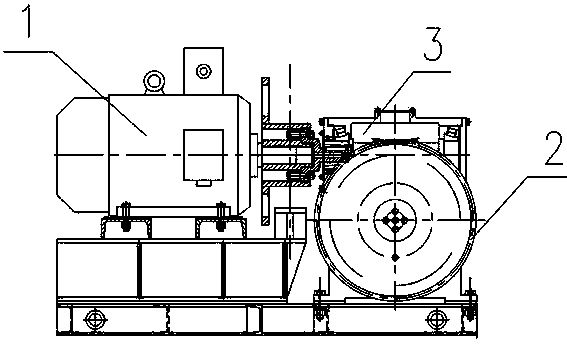

[0011] As one of the best embodiments of a coaxial double-drum self-locking winch of the present invention, see the attached figure 1 , which includes a base on which a drive motor 1, a shaft coupling, a transmission 3, a reel device 2 and other parts are arranged.

[0012] The driving motor 1 is a power source, and it can adopt a variable frequency motor, or even an air motor or a hydraulic motor. The coupling is connected to the output end of the drive motor 1. The coupling adopts an elastic pin coupling, which has good vibration reduction and vibration absorption, and can compensate for the deflection and misalignment of the two shafts when installed; Another feature is that after the fatigue damage of the elastic pin, the shaft of the transmission and the shaft of the motor can still be connected together to ensure safe and reliable transmission. A speed regulating brake is arranged outside the shaft coupling according to the existing method, and the speed regulating belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com