Method for offshore installation of deepwater jacket using airbag

A jacket and airbag technology, which is applied in the field of ocean engineering, can solve the problems of being easily affected by wave force and flow force, increasing the weight of rods, and reducing the ability of rods to resist water pressure, etc., so as to simplify the installation process and reduce the weight , to reduce the effect of environmental force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

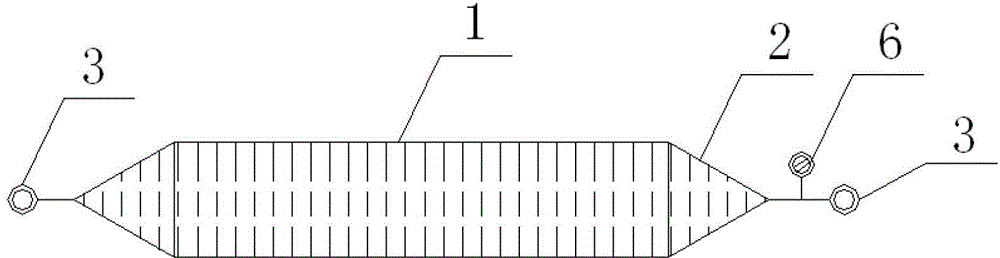

[0053] Such as Figure 1A As shown, the structure of the airbag 1 used in the present invention is: the middle part is a soft buoy, and a conical head 2 is installed at both ends, wherein, the ends of the two conical heads 2 are equipped with suspension rings 3, the conical A barometer 6 is installed on the front end suspension ring 3 of the head 2;

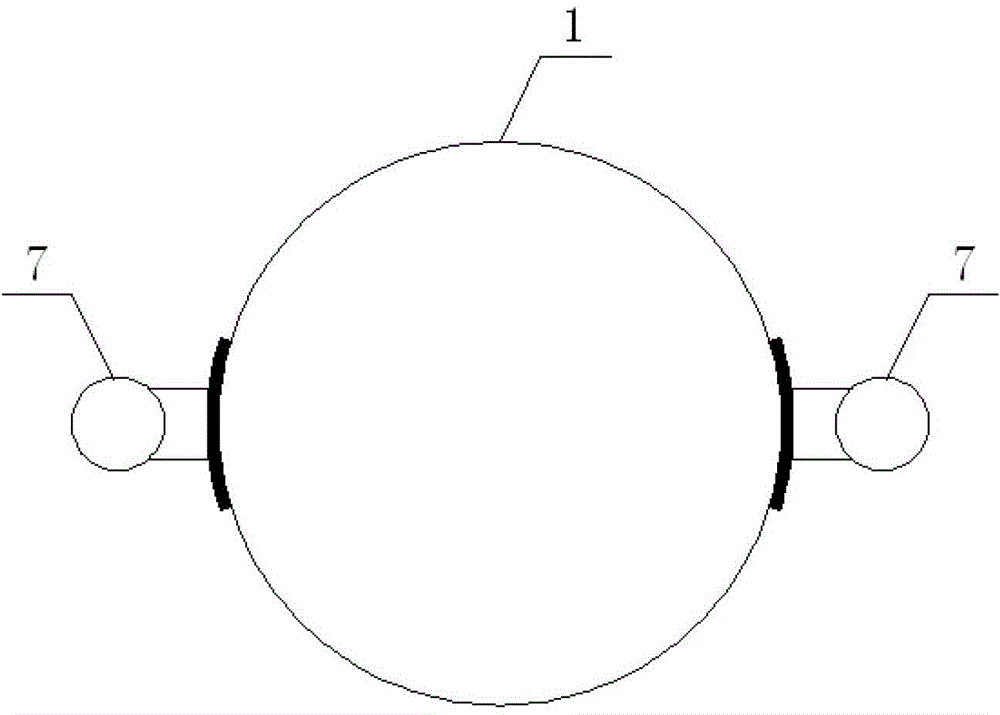

[0054] Such as Figure 1B As shown, several rows of suspension rings 7 are provided on opposite sides of the soft buoy, and the suspension rings 7 can be used for connecting one airbag 1 to another airbag 1 .

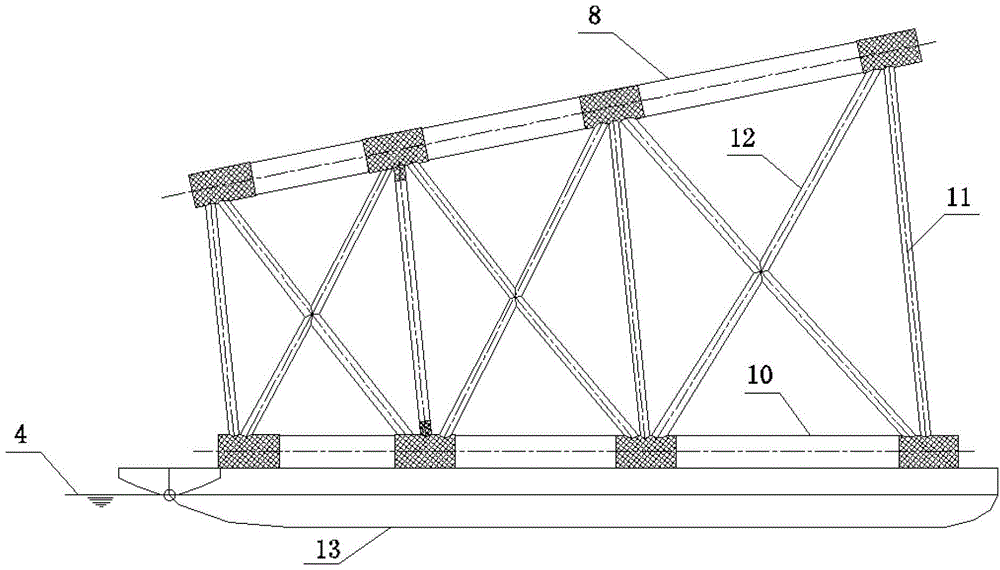

[0055] Such as Figure 2A to Figure 2C As shown, the jacket 8 used in the present invention includes: four main leg members 10, several layers of horizontal members 11 connected to the four main leg members 10 and diagonal bracing members 12 arranged therebetween, through The above connection constitutes a jacket with a tower structure;

[0056] After the jacket 8 is launched, it is in a horizontal self-floating state b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com