Combined type door frame processed in standardized mode and combination method thereof

A combined type and door frame technology, which is applied in the direction of window/door frame, window/door, building components, etc., can solve the problems of difficult to ensure the quality of door frame installation, deformation of all solid wood door frames, and impact on sealing, so as to facilitate standardized processing, Improve the overall use strength and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

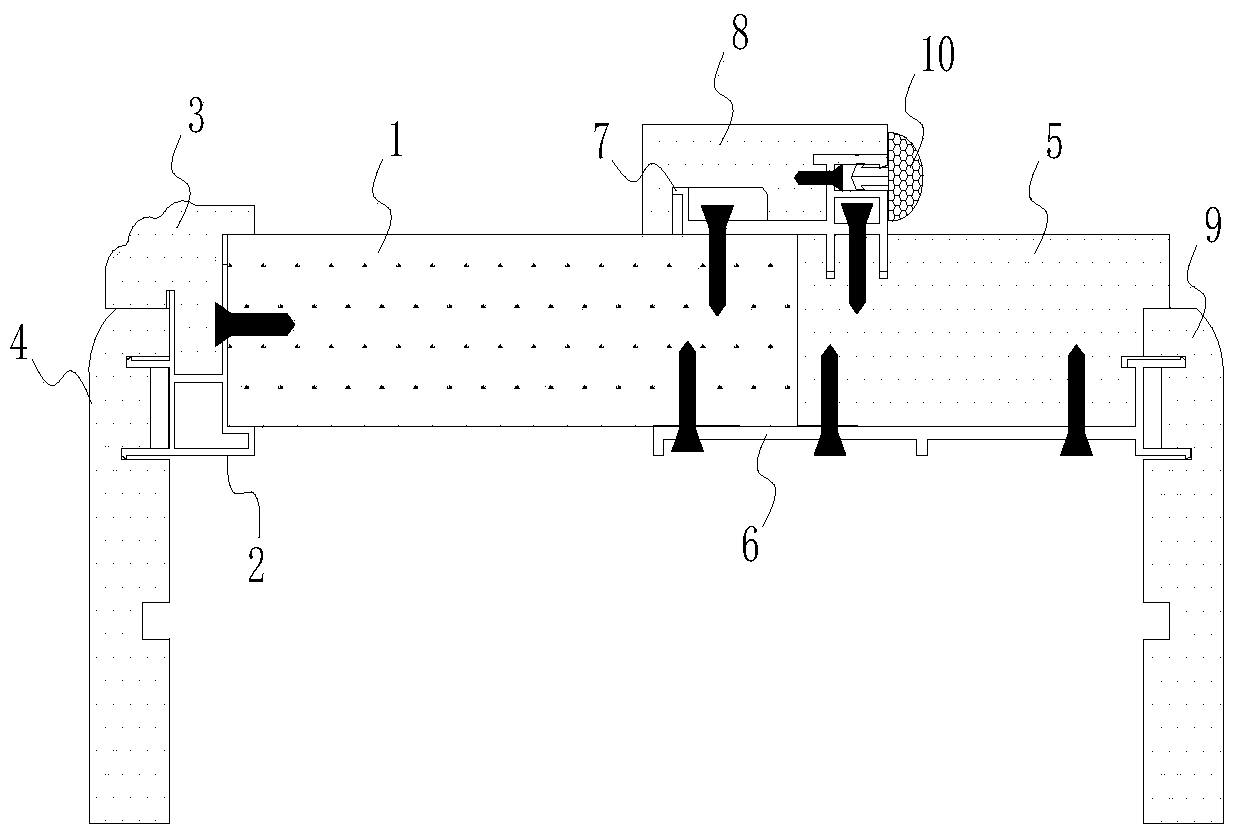

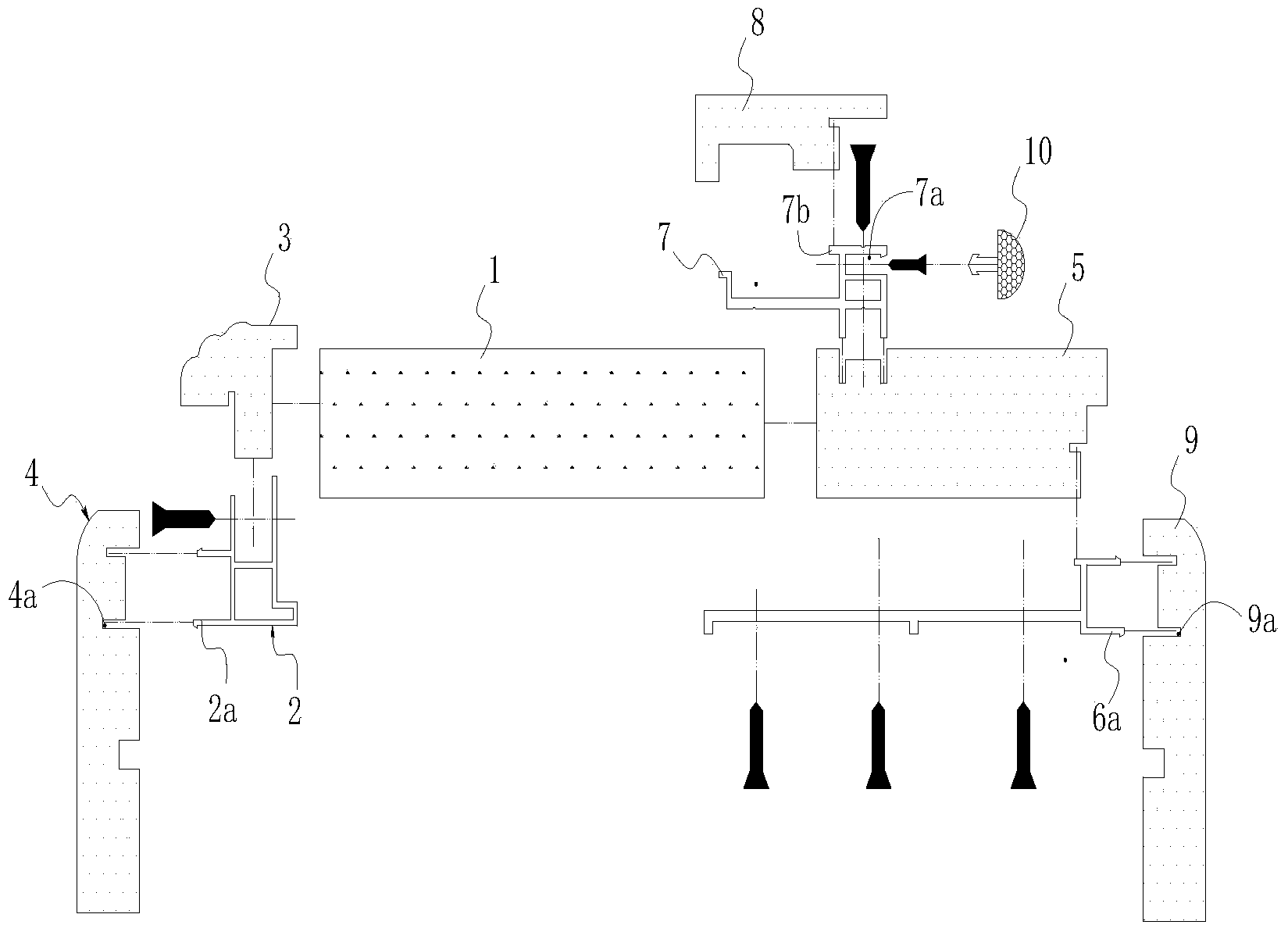

[0025] see figure 1 , figure 2 As shown, a standardized processing modular door frame of the present invention includes a wooden main board 1, a front connector 2 is fixed at the front end of the wooden main board 1 by screws, and a wooden decorative strip 3 and a wooden decorative strip 3 are respectively installed on the front connector 2. Front cover plate 4; the rear part of the wooden main board 1 is provided with a wooden stop plate 5, and the inner side of the wooden main board 1 and the wooden stop plate 5 (that is, the side against the wall) passes through the inner connecting plate 6 Fixed connection, the connection also adopts screws; the outer side of the wooden main board 1 and the wooden stop plate 5 are fixedly connected by an outer connector 7, and the outer side of the outer connector 7 is fixed with a wooden decorative panel 8; the wooden stop A wooden rear cover 9 is installed at the rear end of the board 5 .

[0026] The wooden main board 1 in the presen...

Embodiment 2

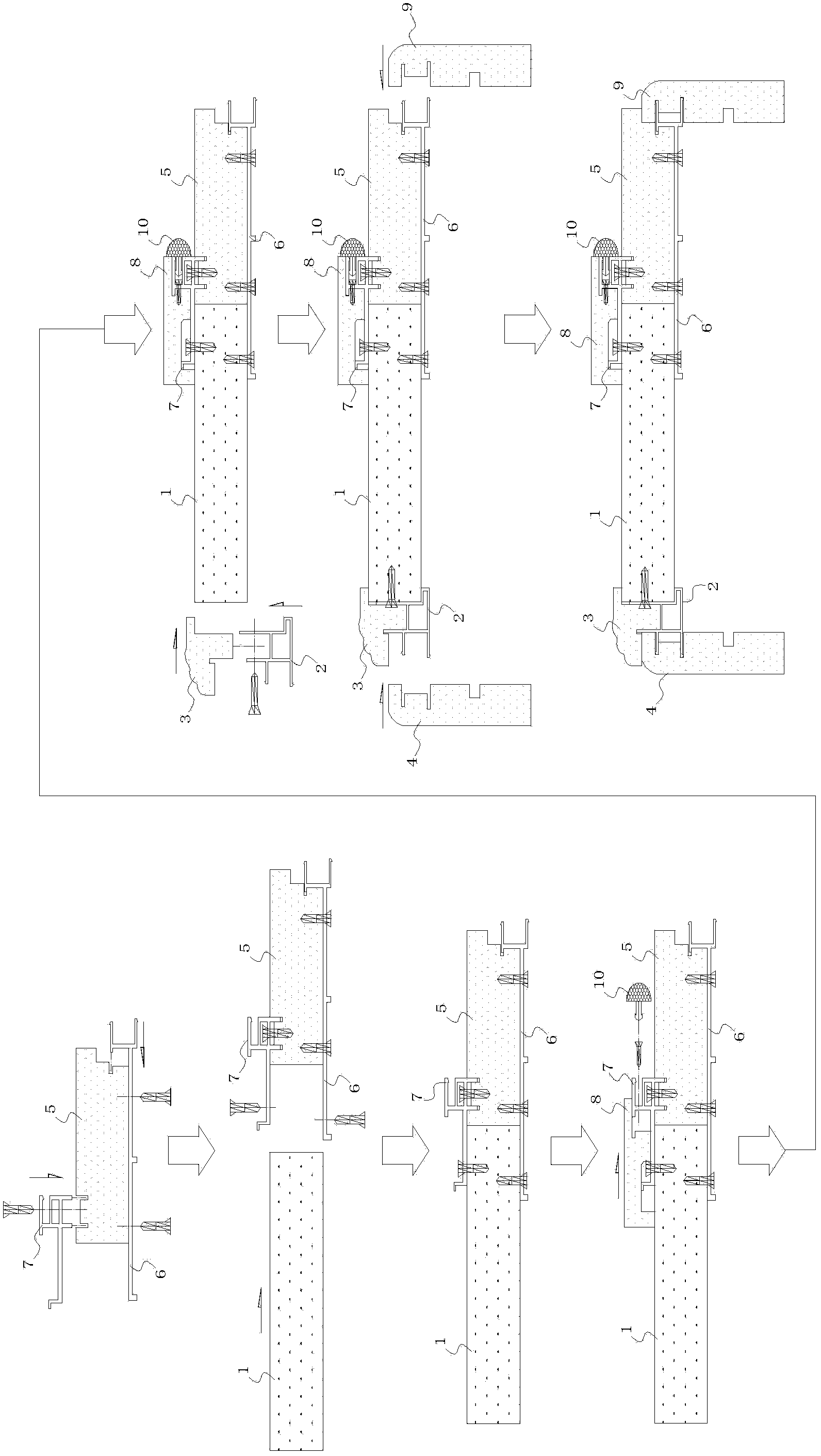

[0044] see Figure 4 As shown in the figure, a standardized processing modular door frame of the present invention is basically the same as Embodiment 1, except that the connection structure between the front connector 2 and the wooden front cover 4 and the wooden decorative strip 3 is different, and the connection structure of the inner connecting plate 6 is different. The connection structure is different from that of the wooden rear cover plate 9, but the technical effect is exactly the same. Only considering the convenience of processing and installation, the present embodiment is more convenient to install than the first embodiment.

[0045] For the specific combined installation of this embodiment, please refer to Figure 5 As shown, it is basically the same as Embodiment 1, and the description is not repeated here.

Embodiment 3

[0047] see Image 6 As shown, another specific embodiment of the present invention is basically the same as the embodiment 1, the difference is that the connecting surface of the inner connecting plate 6 and the wooden stop plate 5 is provided with three connecting bars 6a, and the inner connecting plate 6 and the wooden stop plate 5 are fixedly connected by the above-mentioned three connecting strips 6a embedded in the wooden stop plate 5. This connection method can be formed by a rolling machine in the factory, and the dimensional stability of the processing is higher, and the Requires field screw connections.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com