Exhaust gas heat exchange system of automobile engine

A technology for a heat exchange system and an automobile engine, applied in the field of internal combustion engines, can solve the problems of HC emissions failing to meet the standard requirements, affecting the economic performance of vehicles, and poor quick response of warm air, so as to improve the rapid response performance, save fuel consumption and save energy. effect of fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

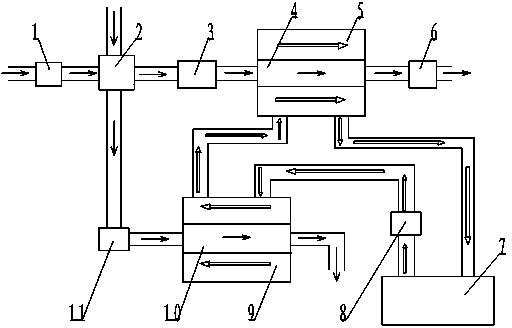

[0016] Referring to Fig. 1, the present invention comprises automobile heater circulation pipeline, engine exhaust pipeline and engine intake pipeline, is full of circulating water medium in the described automobile heater circulation pipeline, and it is connected with the water inlet and the water outlet of automobile heater connection, its special feature is: the first heat exchange water jacket 9 parallel to the engine exhaust pipeline and the second heat exchange water jacket 5 parallel to the engine intake pipeline are provided on the circulation pipeline of the automobile heater. An electronic water pump 8 is also arranged on the fan circulation pipeline, and the electronic water pump 8 is installed between the water outlet of the heater 7 and the water inlet of the first heat exchange water jacket 9, and the electronic water pump 8 is controlled by the engine ECU.

[0017] see figure 1 , the engine exhaust pipeline of the present invention communicates with the turbine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com