Automobile muffler inlet pipe assembly and its layout structure

A technology of automobile muffler and muffler, which is applied in the direction of muffler, exhaust device, machine/engine, etc. It can solve the problems that the engine and muffler cannot be eliminated, the reliability of the exhaust system is affected, and the layout space is limited, so as to eliminate vibration , Good anti-vibration and decoupling effect, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further explain the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

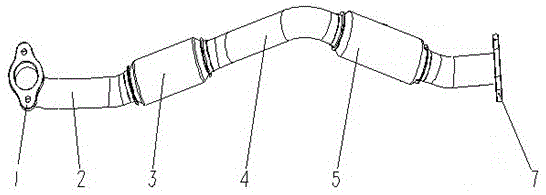

[0015] see figure 1 As shown, the inlet pipe assembly of the automobile muffler is welded by the inlet pipe 2, the first corrugated pipe 3, the connecting pipe 4, the second corrugated pipe 5, and the outlet pipe 6 in sequence. Wherein the length of the first bellows 3 is shorter than the length of the second bellows 5 . The inlet end of the inlet pipe 2 is provided with a first flange 1 for connecting with a three-way catalytic converter 10 . The outlet end of the outlet pipe 6 is provided with a second flange 7 for connecting with a muffler (not shown in the figure).

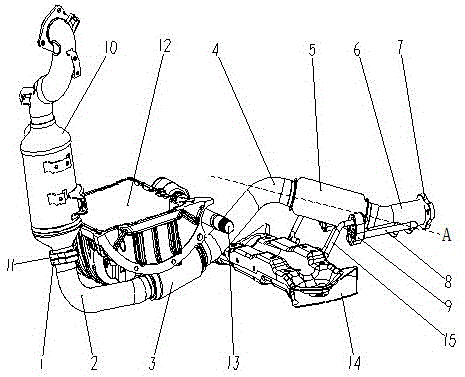

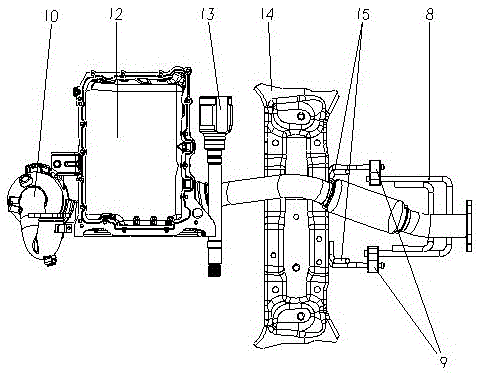

[0016] see figure 2 and image 3 As mentioned above, the arrangement structure of the muffler inlet pipe assembly includes the muffler inlet pipe assembly, the oil pan 12 , the transmission shaft 13 and the subframe 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com