Ball cone irradiation sample stopple with self-locking pressurized water reactor

A technology of pressurized water reactors and balls, which is applied in the direction of engine seals, quick-action fasteners, engine components, etc., can solve the problems of not having self-locking functions, etc., and achieve low processing accuracy requirements, high safety margins, and improved safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

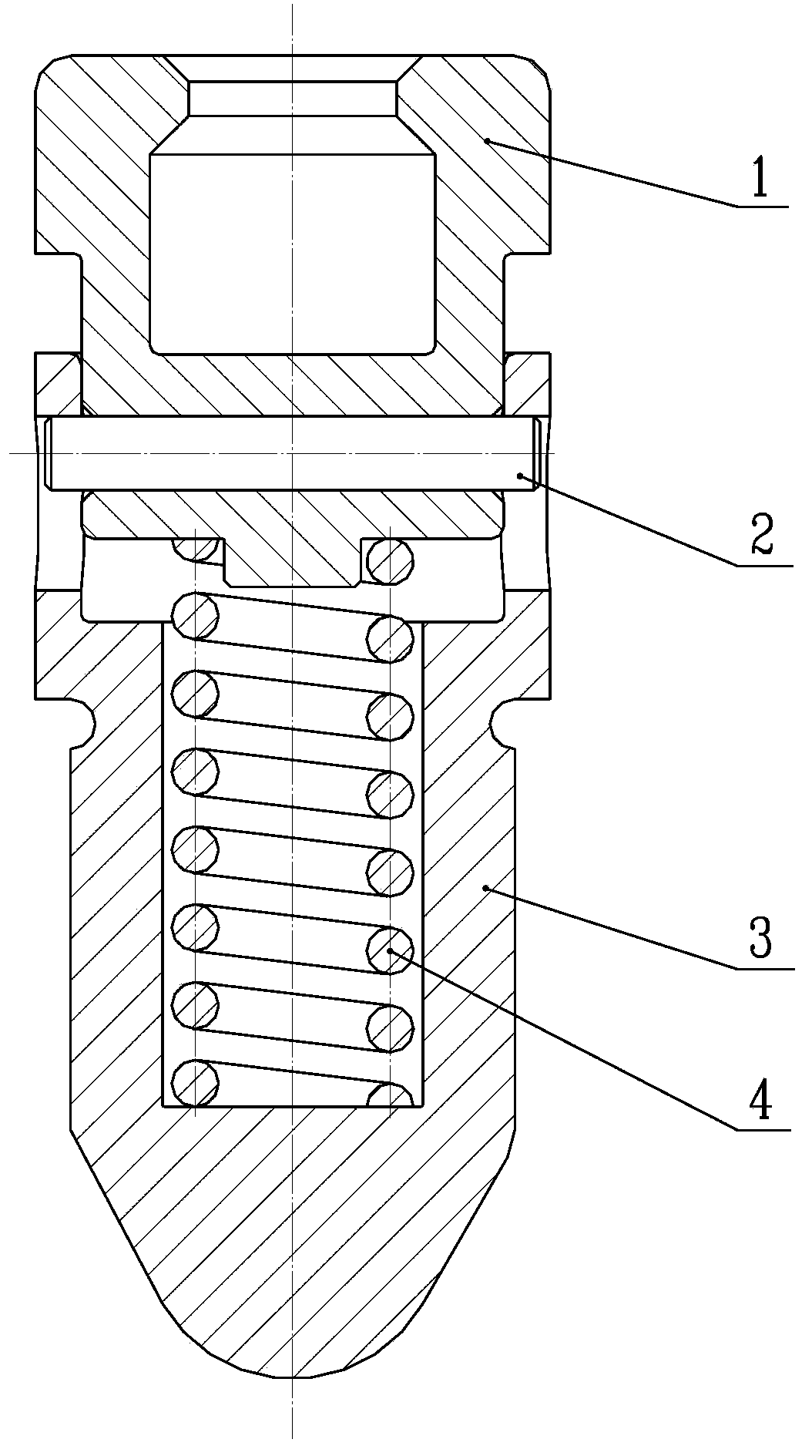

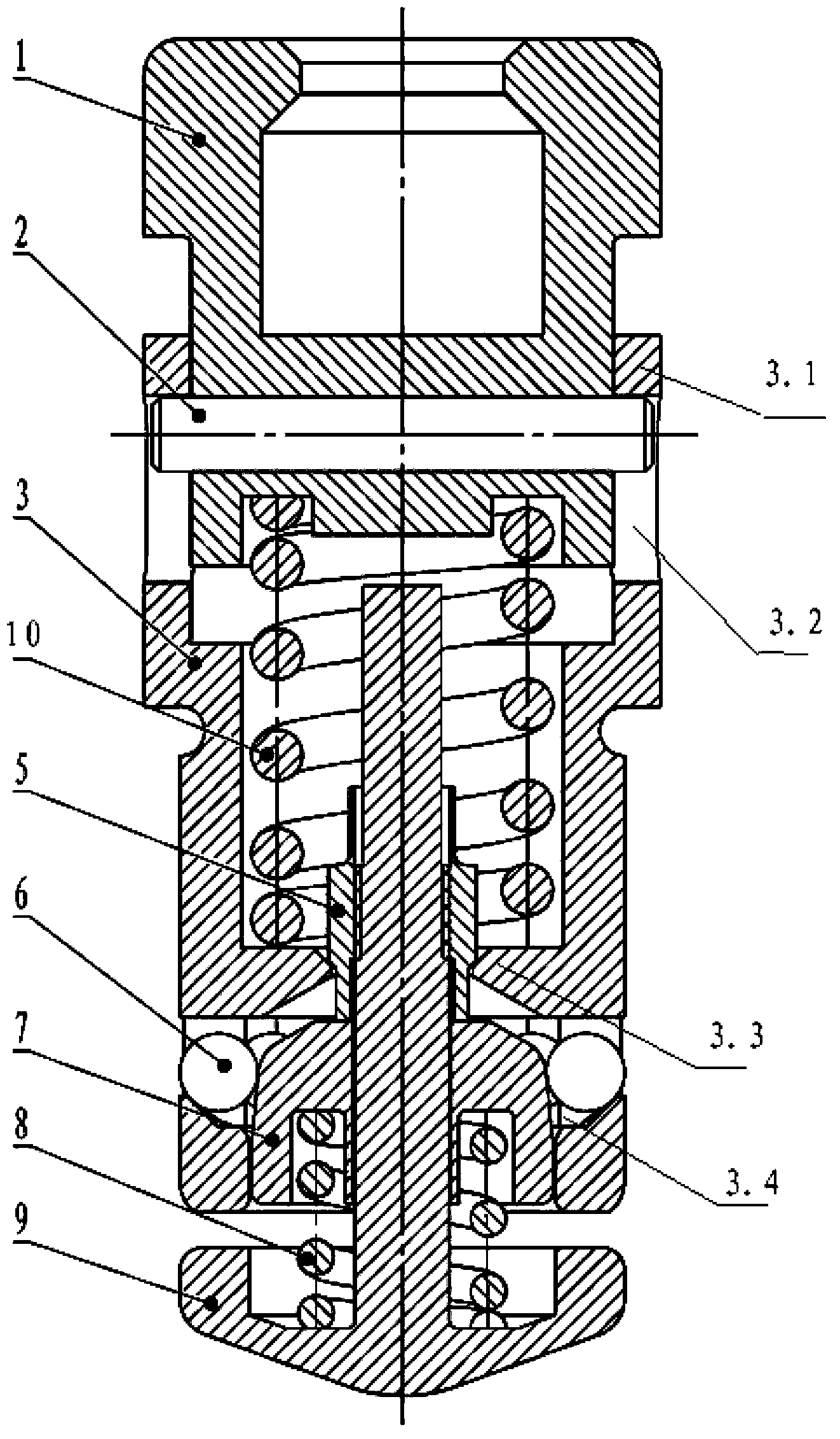

[0015] Such as figure 2 As shown, the irradiation sample hole plug in this embodiment consists of an upper end 1, a base 3, an optical axis 2, a hydraulic push rod 9, a cone ring 7, a ball 6, a lock nut 5, a first spring 10, a second It is composed of two springs 8, which are installed in the irradiation sample hole of the flange of the reactor hanging basket, and the hydraulic push rod 9 pushes the ball 6 to press against the wall of the irradiation sample hole to generate frictional force to realize self-locking.

[0016] The base 3 is integrally formed into a stepped cylindrical shape with an opening, and its upper end is a cup-shaped seat 3.1. Waist-shaped holes 3.2 are processed on both sides of the side wall of the cup-shaped seat 3.1, and steps 3.3 are processed on the inner wall of the cavity of the base 3. The above step 3.3 is a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com