Gyroscope of single-shaft micro electro mechanical system

A micro-electromechanical system and gyroscope technology, which is applied to gyroscope/steering sensing equipment, gyroscope effect for speed measurement, instrument and other directions, can solve the problem of large measurement result error, achieve small result error, good anti-vibration performance, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

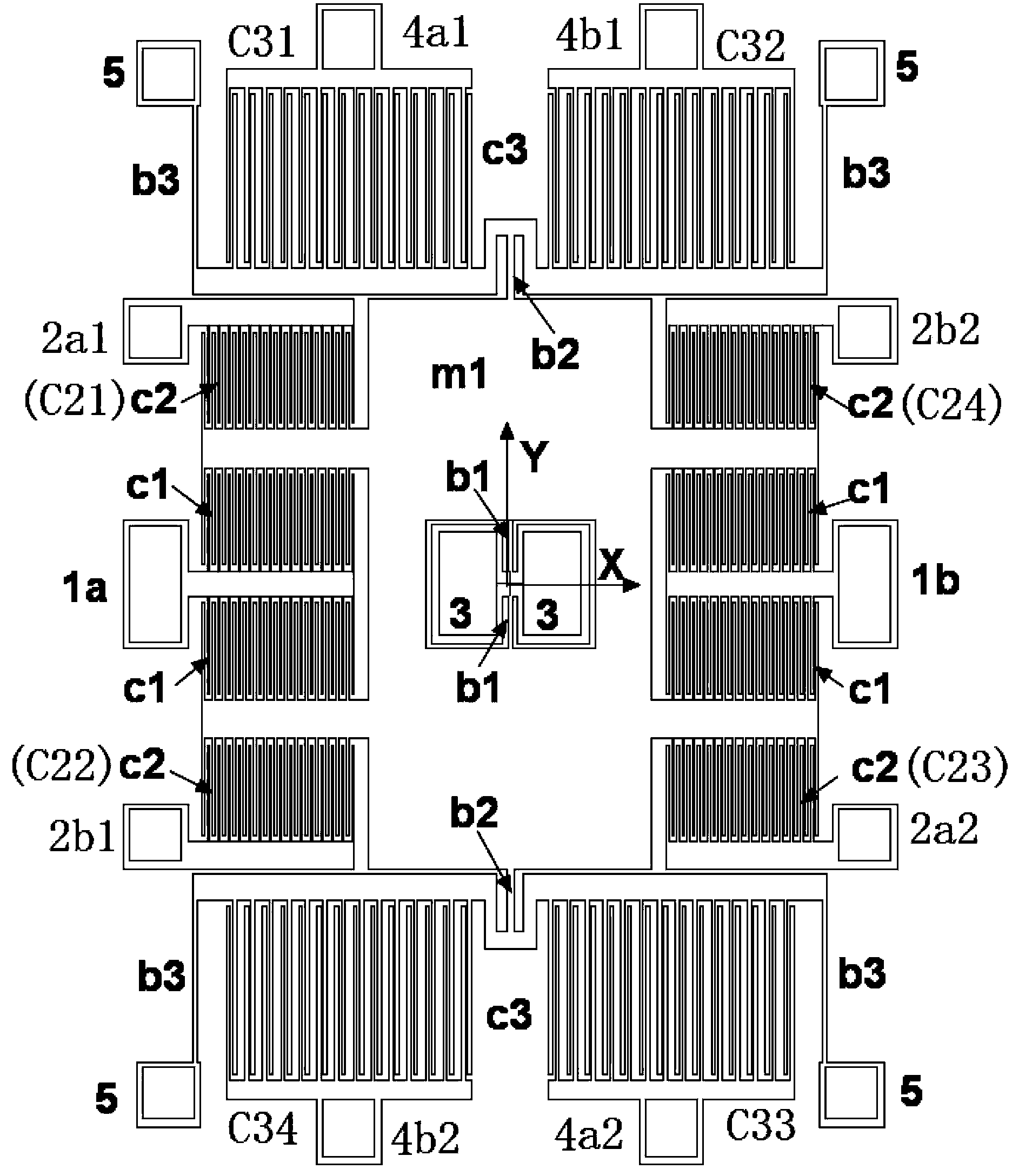

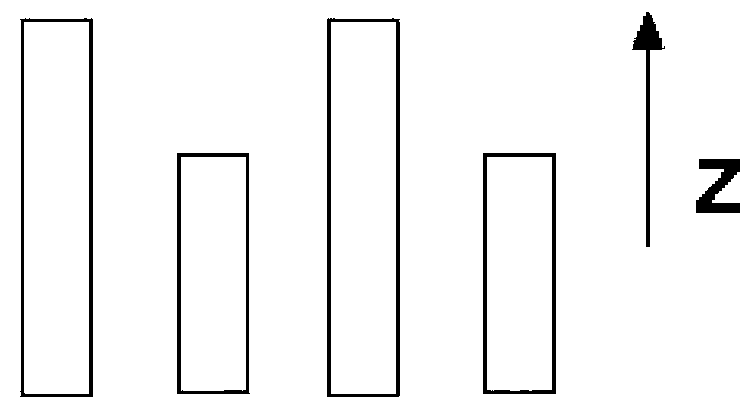

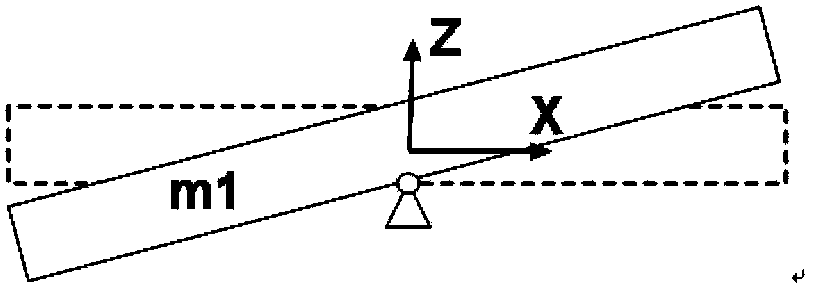

[0022] The specific structure of the single-axis MEMS gyroscope of the present invention will now be described by setting two pairs of driving capacitor groups C1, two pairs of detecting capacitor groups C2 and two pairs of sensitive capacitor groups C3 as an example. Define the x-axis direction of the Cartesian coordinate system with the center of the twisting mass m1 as the origin as the left and right directions, and the y-axis direction as the up and down directions, and the fixed and movable combs of each capacitor group have The height difference in the axial direction, such as figure 1 As shown, there are anchor points distributed around the twisting mass m1, and the area between the anchor point and the twisting mass m1 is the capacitor group setting area for setting various capacitor groups. The left, right, upper and lower capacitor g...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap