Self-inspection type temperature probe detection circuit

A detection circuit and temperature probe technology, applied in the direction of thermometer testing/calibration, thermometers, measuring devices, etc., can solve the problems that the detection results are easily affected by human factors, time-consuming and laborious, and affect the accuracy of the detection results, so as to improve the detection results. Speed and detection accuracy, excluding the influence of human factors, the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

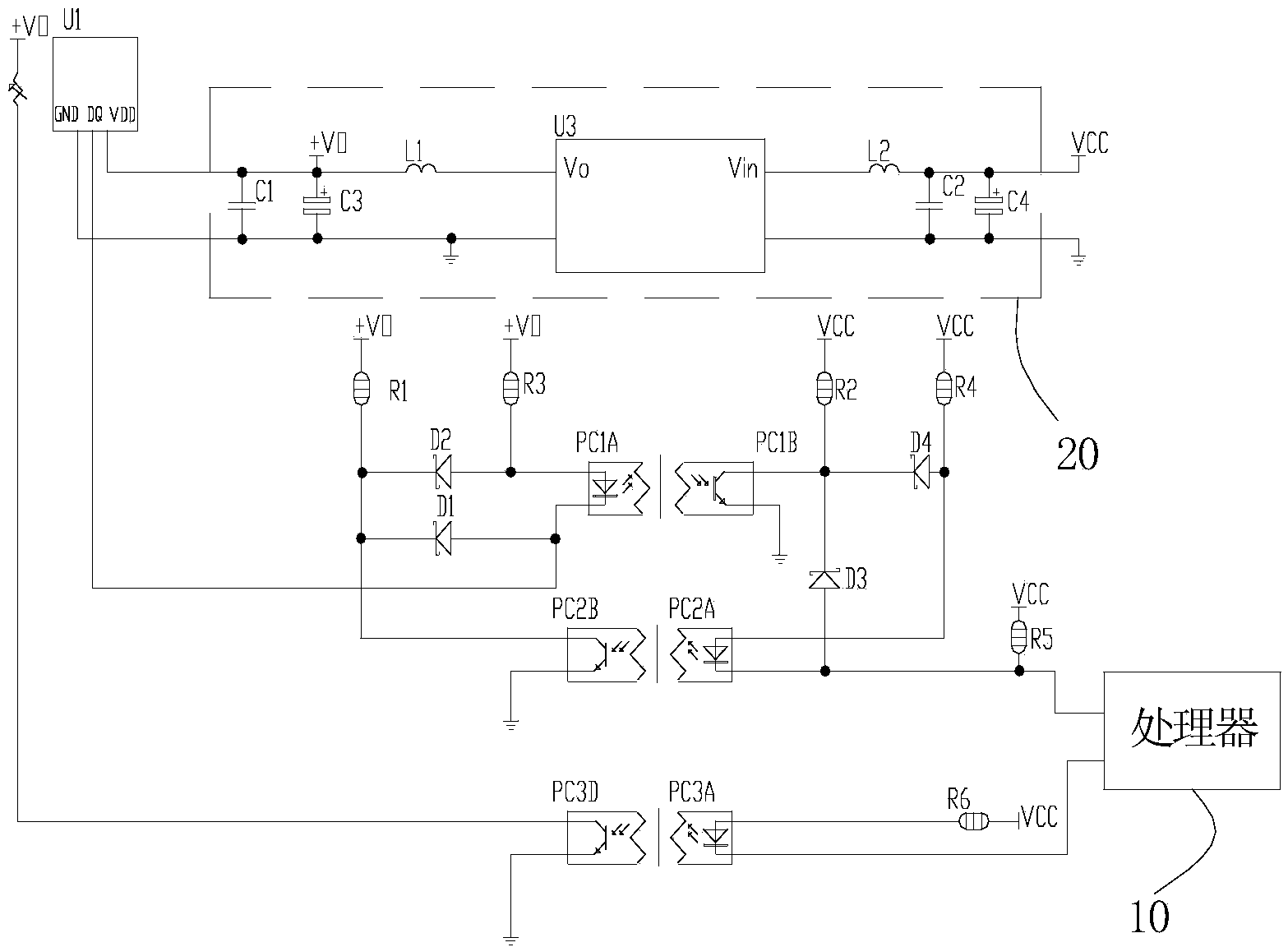

[0022] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

[0023] See figure 1 , the present invention relates to a self-checking temperature probe detection circuit, and its preferred embodiment includes a digital temperature probe U1, a master optocoupler PC2, a slave optocoupler PC1, a processor 10, a diode D1 to a diode D4, for providing a direct current Voltage supply module 20, resistors R1 to resistors R5. The master photocoupler PC2 is composed of a master light emitter PC2A and a master photoreceiver PC2B, and the slave photocoupler PC1 is composed of a slave emitter PC1A and a slave photoreceiver PC1B.

[0024] The anode of the main light emitter PC2A is connected to the power supply module 20 through a resistor R4, the negative pole of the main light emitter PC2A is connected to the processor 10, and connected to the power supply module 20 through a resistor R5, and the output end of the main li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com