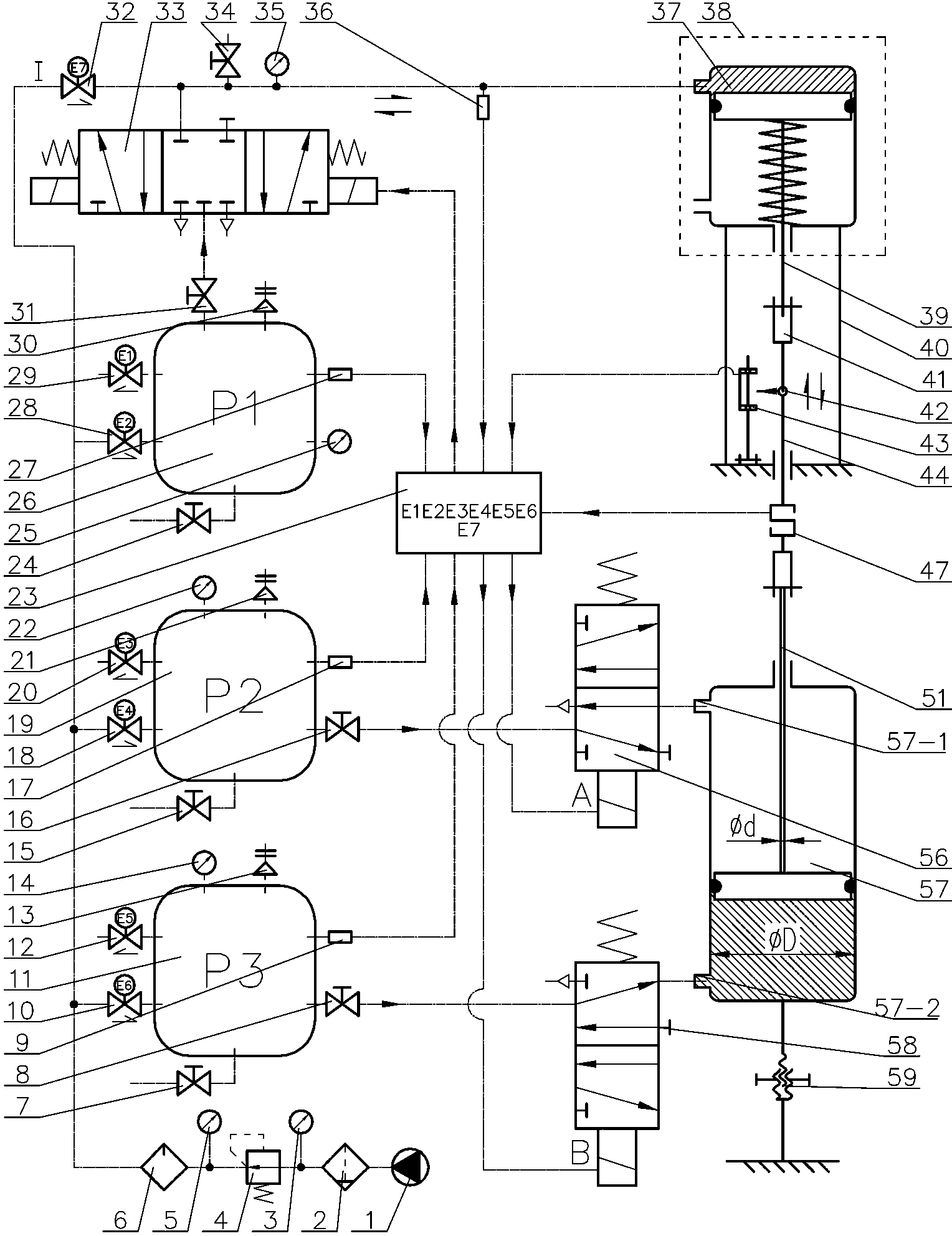

Linear valve pneumatic actuator testing device

A pneumatic actuator and pneumatic execution technology, applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve problems such as opening and closing failures, inaccurate control, and force values that cannot meet the specified requirements, and achieve maintenance The effect of low cost, high test accuracy and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] The working principle of embodiment one is as follows:

[0076] When carrying out the no-load test, sealing test and strength test, only the high-pressure air source is used as the power to drive the single-acting linear valve pneumatic actuator sample 37 to move. At this time, the second gas storage tank 19 and the third gas storage tank 11 and the back pressure Cylinder 57 all does not act.

[0077] During the load test and action life test, the sample 37 of the single-acting linear valve pneumatic actuator is divided into two stages of motion process: forward and downward and reset and rising:

[0078] (1) When the sample 37 of the single-acting linear valve pneumatic actuator moves forward and falls, the first gas storage tank 26 provides pressure to push the single-acting linear valve pneumatic actuator sample 37 to move. At this time, the second gas storage tank 19 provides The pressure is given to the first port 57-1 of the back pressure cylinder as the load out...

Embodiment 2

[0082] The rest of the structure of the second embodiment is the same as that of the first embodiment.

[0083] The working principle of the second embodiment differs from that of the first embodiment in that the first gas storage tank 26, the second gas storage tank 19 and the third gas storage tank 11 do not operate during the no-load test, sealing test and strength test , from gas source 1 through the first high-pressure supply pipeline to the first port of the double-acting linear valve pneumatic actuator sample for experiments, and from gas source 1 to the double-acting linear valve pneumatically actuated through the second high-pressure supply pipeline The second port of the device sample is supplied with air for experiments, and the compressed air in the first high-pressure supply pipeline is controlled by the first high-pressure solenoid valve and the compressed air in the second high-pressure supply pipeline is controlled by the second high-pressure solenoid valve. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com