Electrostatic discharge detection circuit and processing system

An electrostatic discharge detection and circuit technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of narrow detection range, inability to detect electrostatic voltage, etc., and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

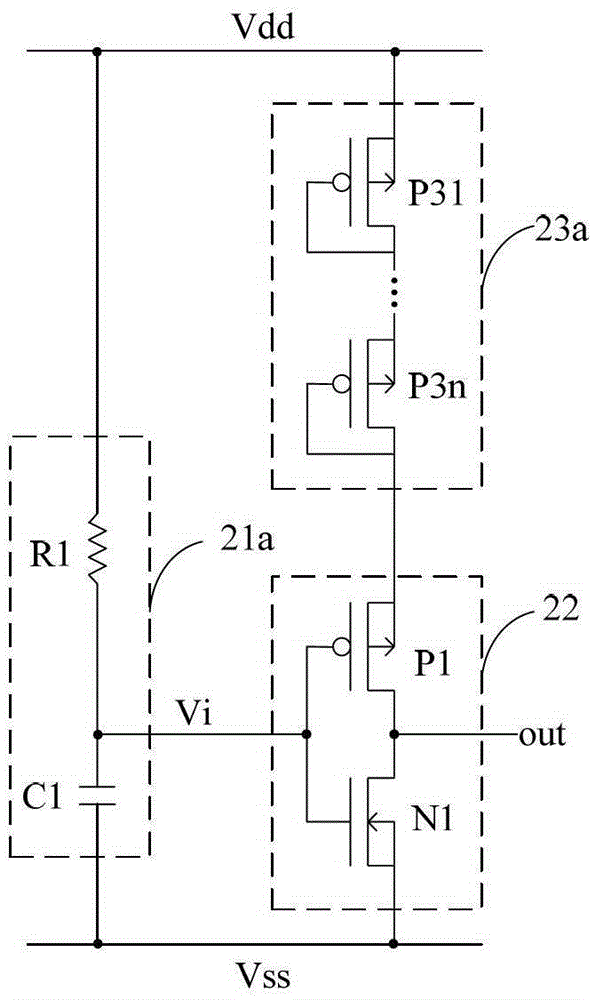

[0049] image 3 is a circuit diagram of an electrostatic discharge detection circuit according to Embodiment 1 of the present invention.

[0050] refer to image 3 , the sampling unit 21a includes a first impedance element R1 and a first capacitive reactance element C1. One end of the first impedance element R1 is connected to the first power supply line Vdd, and the other end of the first impedance element R1 is connected to one end of the first capacitive reactance element C1 and used as the sampling unit 21a to output the control The output terminal of the voltage Vi. The other end of the first capacitive reactance element C1 is connected to the second power line Vss.

[0051] The first impedance element R1 may be composed of various devices including resistors, including polysilicon resistors, active region resistors, well resistors, or MOS channel resistors. The first capacitive reactance element C1 may be composed of capacitors, including polysilicon-insulator-polysi...

Embodiment 2

[0067] Figure 4 is a circuit diagram of an electrostatic discharge detection circuit according to Embodiment 2 of the present invention. refer to Figure 4 , the difference between Embodiment 2 and Embodiment 1 is that the sampling unit 21b includes the first impedance element R1 and the first capacitive reactance element C1, and also includes a second impedance element R2, and the first capacitive reactance element C1 passes The second impedance element R2 is connected to the first impedance element R1, and the connection end of the first impedance element R1 and the second impedance element R2 is used as the output end of the sampling unit 21b to output the control voltage Vi .

[0068] The second impedance element R2 may be composed of various devices including resistors, including polysilicon resistors, active region resistors, well resistors, or MOS channel resistors.

[0069] In this embodiment, the sampling unit 21b includes the second impedance element R2, the seco...

Embodiment 3

[0071] Figure 5 is a circuit diagram of an electrostatic discharge detection circuit according to Embodiment 3 of the present invention. refer to Figure 5 , the difference between embodiment 3 and embodiment 1 is that: the first impedance element R1 and the first capacitive reactance element C1 exchange positions, that is, one end of the first impedance element R1 is connected to the second power line Vss , the other end of the first impedance element R1 is connected to one end of the first capacitive reactance element C1 and serves as the output end of the sampling unit 21c to output the control voltage Vi, and the other end of the first capacitive reactance element C1 is connected to the Describe the first power line Vdd.

[0072]In this embodiment, when the electrostatic voltage generated by electrostatic discharge does not appear on the first power line Vdd, the control voltage Vi is pulled to a low potential through the first impedance element R1, therefore, the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com