Micro-seismic monitoring three-component sensor

A microseismic monitoring and sensor technology, applied in seismic signal receivers and other directions, can solve the problems of difficulty in further improving the accuracy of microseismic source positioning, energy calculation accuracy, difficulty in clearly identifying P-wave and S-wave, and affecting rock mass rupture type identification, etc. Achieve the effect of preventing breakage, shielding the influence of electrical noise, and improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

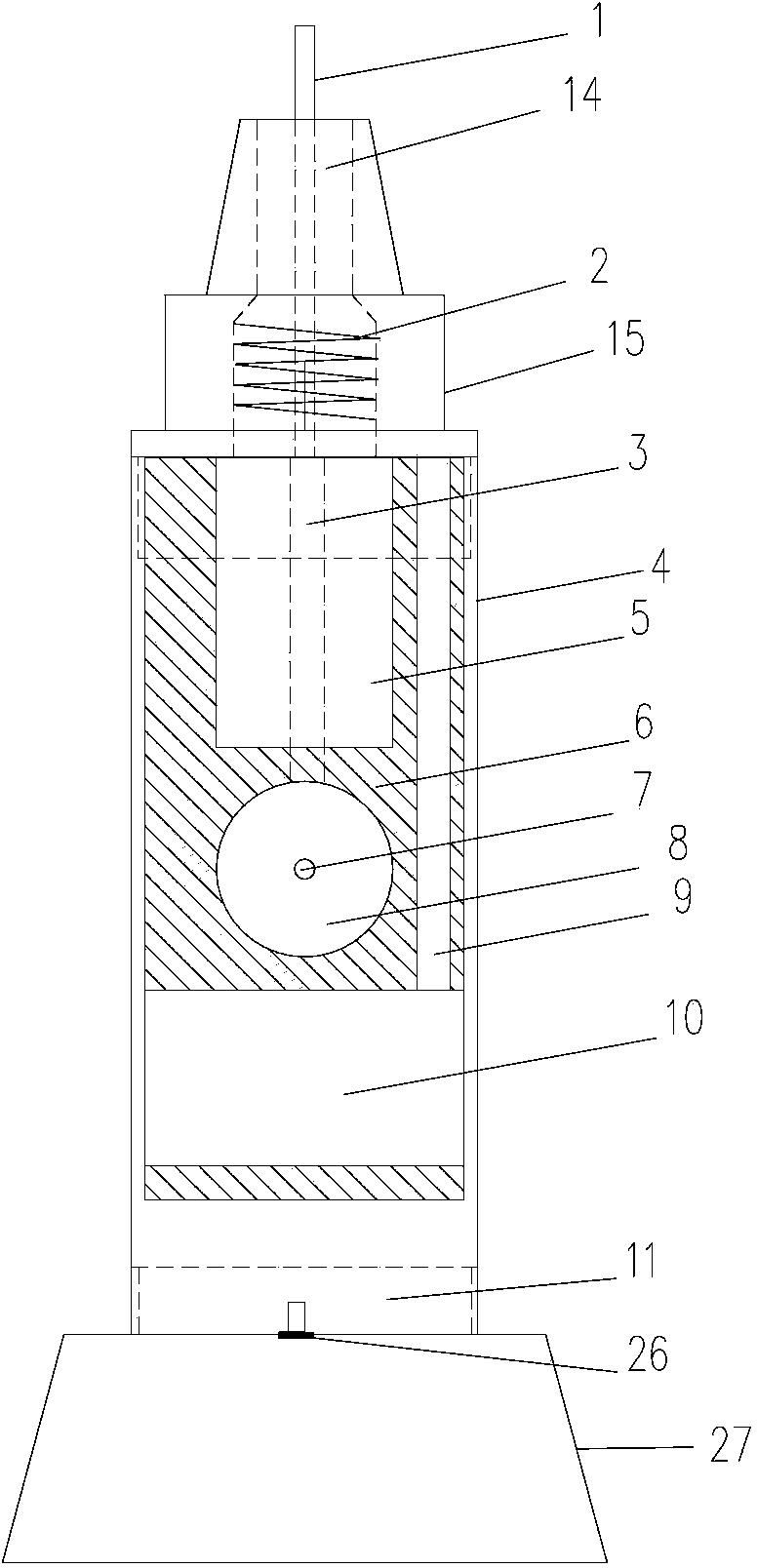

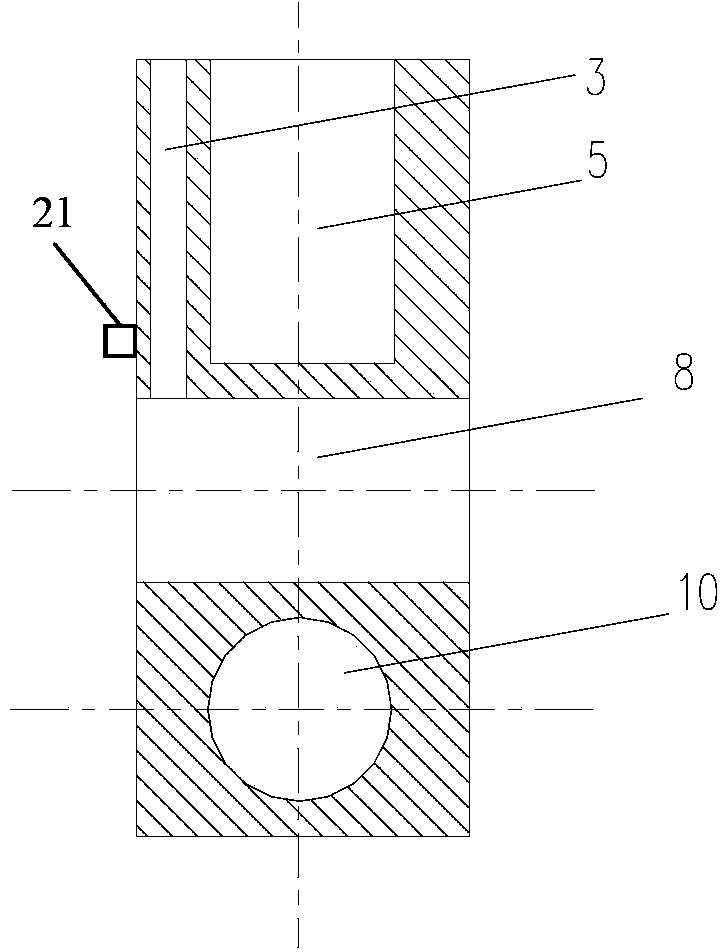

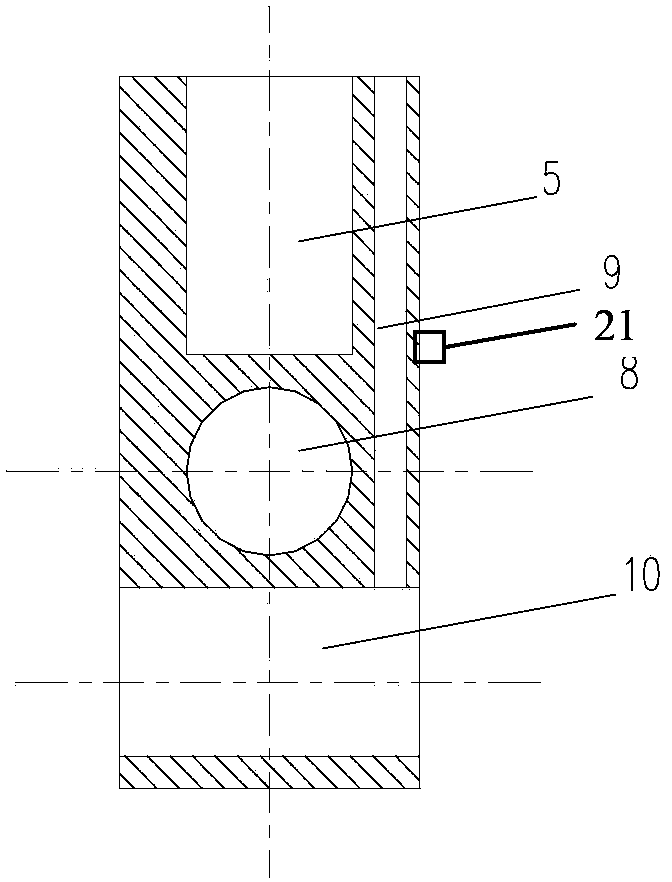

[0064] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0065] A three-component sensor for microseismic monitoring, which includes a sensor signal line 1, a spring retaining ring 2, a first outlet hole 3, a stainless steel shell 4, an axial sensor core 5, a sensor base 6, a direction identification mark 7, a first Radial sensor core 8, second wire outlet hole 9, second radial sensor core 10, bottom cover 11, top cover inner thread 12, bottom cover inner thread 13, main outlet hole 14, outer hexagonal mounting joint 15 , top cover external thread 16, shielding wire welding groove 17, bottom cover external thread 18, sensor fixing hole 19, spring retaining ring placement cavity 20, base fixing column 21, guide groove 22, single component sensor core terminal 23, Single-component sensor core best receiving direction 24, sensor top cover 25, connecting stud 26, anchoring agent container 27, inner hexagonal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com