Automatic control system of fracturing truck

An automatic control system and fracturing truck technology, applied in the drilling automatic control system, general control system, control/adjustment system, etc., can solve the problem of data monitoring, large collection workload, inability to observe monitoring in time, short transmission distance, etc. problems, to reduce the monitoring difficulty, improve the monitoring efficiency, and centralize the monitoring data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

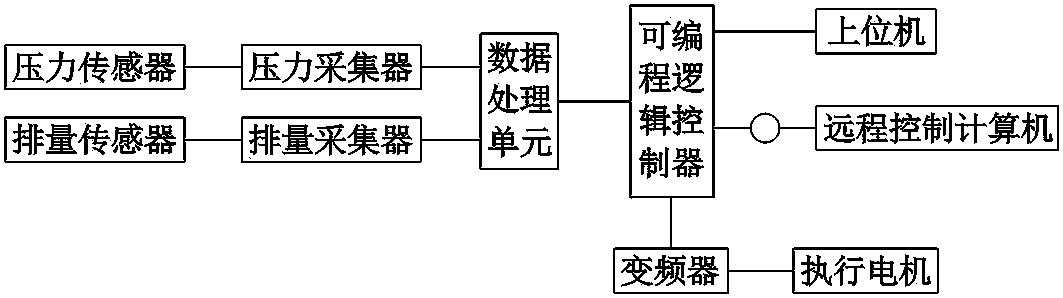

[0010] Such as figure 1 As shown, the automatic control system of the fracturing vehicle includes a host computer, a programmable logic controller, a data acquisition system and a control actuator. The data acquisition system includes a pressure sensor, a displacement sensor, a pressure collector and a displacement collector. The actuator includes a frequency converter and an executive motor. The output of the pressure sensor is connected to the input of the pressure collector, the output of the displacement sensor is connected to the input of the displacement collector, and the outputs of the pressure collector and the displacement collector are connected to the data processing unit. Connection, the data processing unit is connected to the programmable logic controller, the output of the programmabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com