Deep treatment system of wastewater

A sewage system and advanced treatment technology, applied in the direction of aerobic process treatment, sustainable biological treatment, special compound water treatment, etc., can solve the problem of unsustainable and perfect operation of ordinary artificial systems, the need for special personnel to operate, and high energy consumption of integrated equipment problem, to achieve the effect of automatic stability of operation, improvement of processing effect, and improvement of consumption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

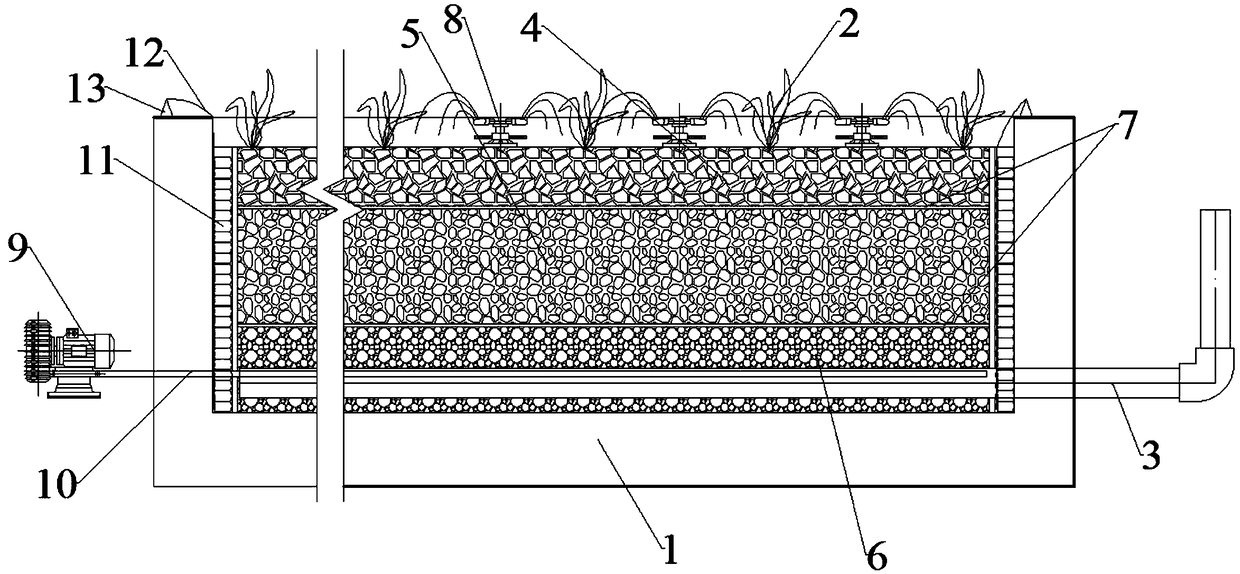

[0042] Example 1: Arrange the collection pipeline at the bottom of the pool body, and then lay a 50nm pebble layer at the bottom of the pool body, with a filling height of 300mm; spread neutral volcanic rock on the top, with a particle size of 30-50mm, and a filling height of 400mm; A porous membrane for evenly distributing waste water is set between the material ginger stone layer and the filler layer; the processing particle size is 20-30 mm, and the filling height is 200 mm; then plant quinces on the top layer, and set the water inlet component on the top layer. Harvest plants regularly and in a timely manner during operation. Check indicators regularly.

[0043] According to the COD determination experiment national standard method (HJ828-2017), the average COD concentration of the system influent is 225.6mg / l, and the average COD concentration of the treated water flowing out of the collection pipeline is 93.4mg / l. Average removal rate: 58.6%.

[0044] According to the ...

Embodiment 2

[0046]Embodiment 2: Arrange the collection pipeline at the bottom of the pool body, set micro-nano aeration components in the collection pipeline, and regularly aerate, and then lay a 50nm pebble layer at the bottom of the pool body, with a filling height of 300mm; spread neutral volcanic rock on the top, particle size The filling height is 30-50mm, and the filling height is 400mm; then lay a ginger stone layer on it, and a porous membrane for evenly distributing the waste water is arranged between the filling layers; the processing particle size is 20-30mm, and the filling height is 200mm; then on the top layer Plant the quinces, and set the water inlet components on the uppermost layer. Harvest plants regularly and in a timely manner during operation. Check indicators regularly.

[0047] According to the national standard method of COD determination experiment (HJ828-2017), the average COD concentration of the system influent is 247.9mg / l, and the average COD concentration ...

Embodiment 3

[0050] Embodiment 3: Install steel mesh on both sides of the pool body, arrange the collection pipeline at the bottom of the pool body, set micro-nano aeration components in the collection pipeline, aerate regularly, and then lay a 50nm pebble layer on the bottom of the steel mesh, fill The height is 300mm; the surface is covered with neutral volcanic rock, the particle size is 30-50mm, and the filling height is 400mm; and then the ginger stone layer is laid on the top, and a porous membrane for evenly distributing waste water is arranged between the filler layers; the processing particle size is 20-50mm. 30mm, the filling height is 200mm; then plant the quince on the uppermost layer, set the water inlet component on the uppermost layer, and place the nutrition package between the steel mesh and the pool body. The nutrition package 11 consists of: nutrition beads that provide microbial nutrients, package The water-permeable bag of nutritional beads is filled with sand in the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com