Automatic Control System of Sand Mixer

A technology of automatic control system and sand mixer, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of data monitoring, large collection workload, inability to observe and monitor in time, and short transmission distance, etc. The effect of reducing the difficulty of monitoring, improving the monitoring efficiency, and ensuring the quality of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

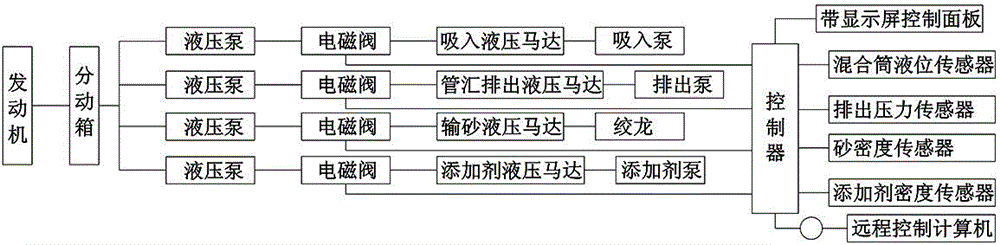

[0016] Such as figure 1 As shown, the automatic control system of the sand mixing vehicle includes a control panel with a display screen, a controller, a parameter acquisition system and a control actuator. The parameter acquisition system includes a mixing cylinder liquid level for monitoring the liquid level in the mixing cylinder sensor, a discharge pressure sensor for monitoring the outlet pressure of the discharge pump, a sand density sensor for monitoring the sand density, and an additive density sensor for monitoring the additive density, and the control actuator includes a suction hydraulic motor and a manifold discharge hydraulic motor , the sand conveying hydraulic motor and the additive hydraulic motor, the four hydraulic motors are respectively connected with corresponding hydraulic pumps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com