Paper feeding mechanism of full-automatic battery plate package machine

A paper feeding mechanism, fully automatic technology, applied in the direction of lead-acid battery, lead-acid battery construction, transportation and packaging, can solve the problems of low processing efficiency, different structure, complexity, etc., to reduce design and manufacturing costs, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

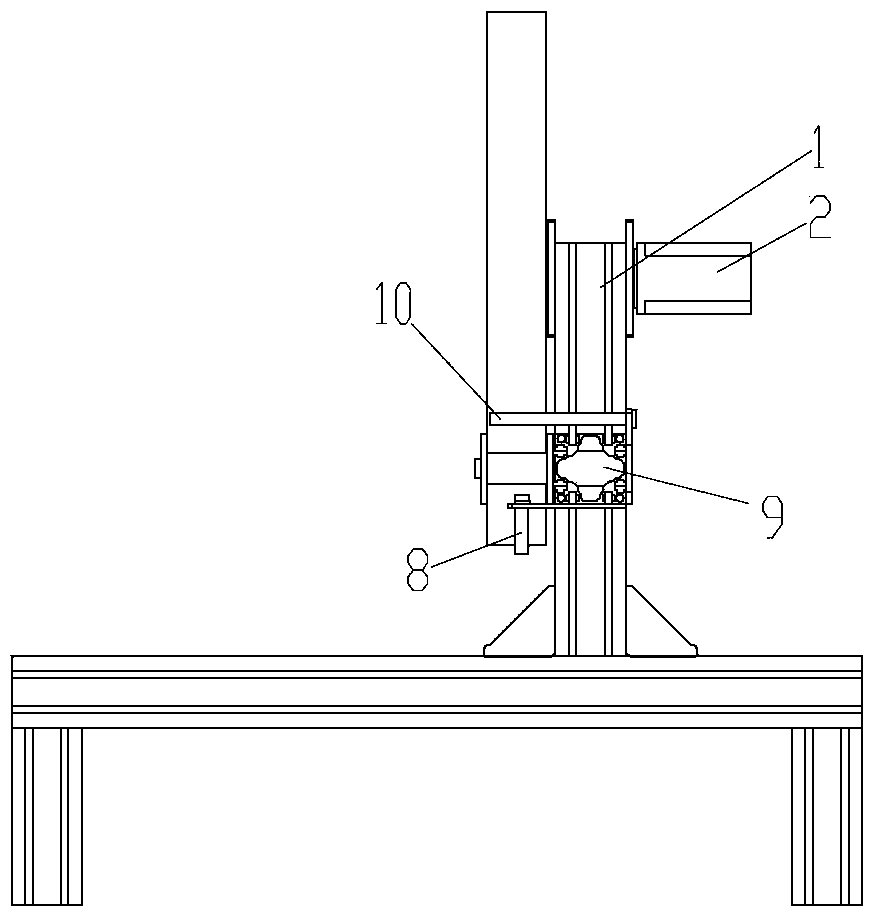

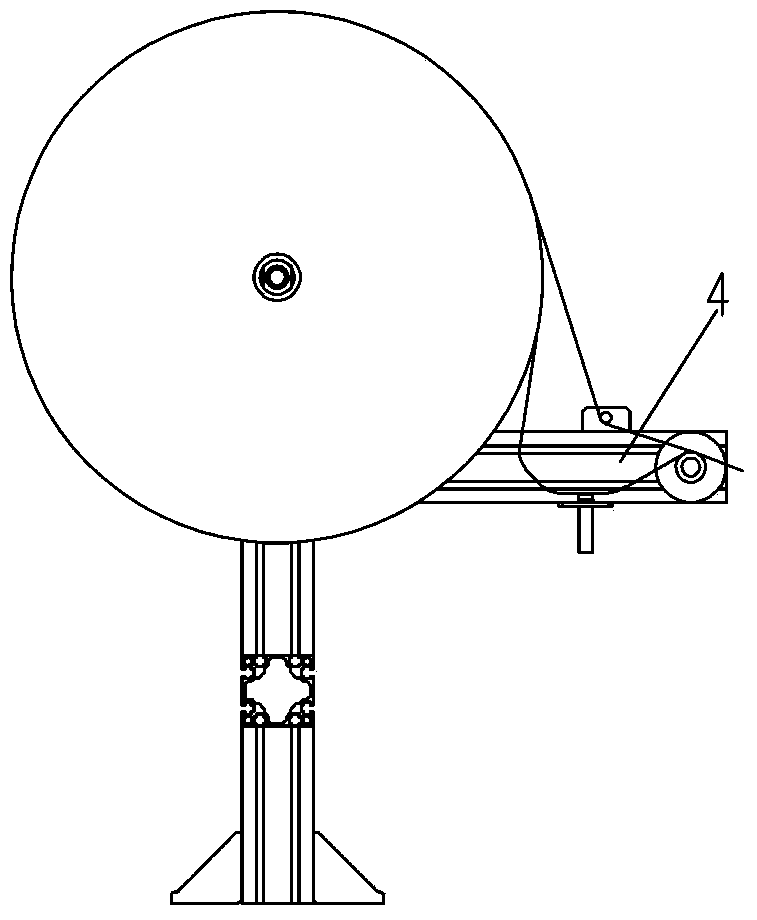

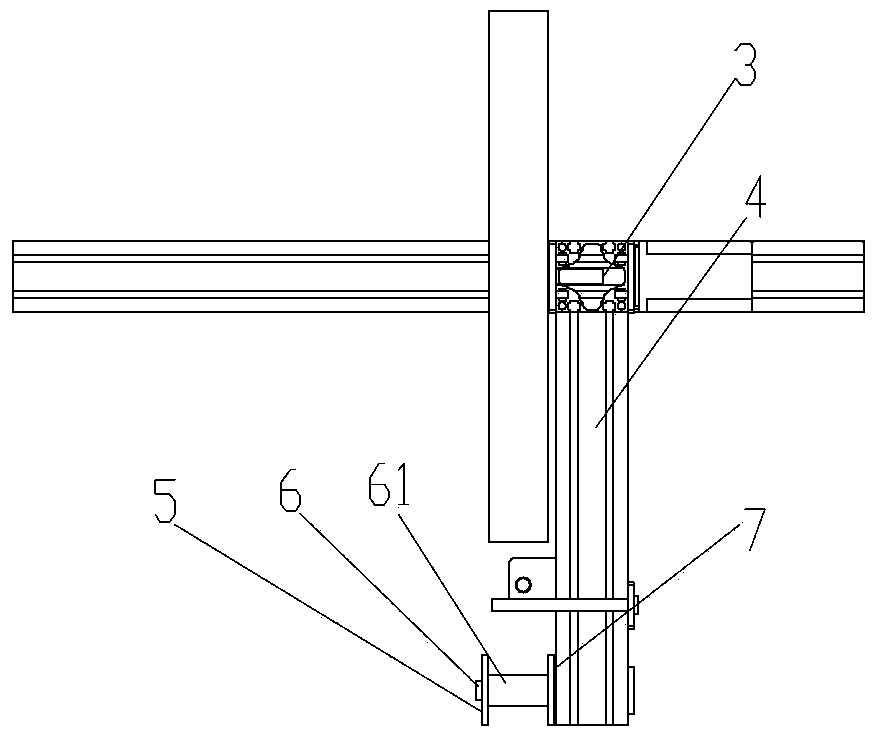

[0023] Such as figure 1 , figure 2 , image 3 As shown, the paper feeding mechanism of the battery plate automatic wrapping machine of this embodiment includes a support column 1, and the support column 1 is provided with a stepping motor 2, and the stepping motor 2 is connected to a paper tape roll. Rotating shaft 3, install the paper tape roll on the rotating shaft 3 when in use, the paper tape goes around the gear bar 10 from the bottom, and then goes around the guide bar 6 from the top, and the distance measuring photoelectric switch 8 detects whether the paper tape is stretched or not. Tight, tightness means that the paper tape needs to be fed, and the distance measuring photoelectric switch 8 gives a signal to make the stepper motor 2 rotate, thereby driving the rotating shaft 3 to rotate, and realizes its own automatic unfolding. When the length of the paper feeding reaches a certain level, it will make the The distance between the paper tape and the distance-measuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com