Metal powder mixing device

A metal powder and internal mixing technology, which is applied in the direction of mixers with rotating stirring devices, dissolving, mixing machines, etc., can solve the problems that affect the quality of injection molding products, and the metal powder cannot be evenly mixed, so as to achieve metal powder and bonding Uniformity of agent, improvement of good rate, comprehensive effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

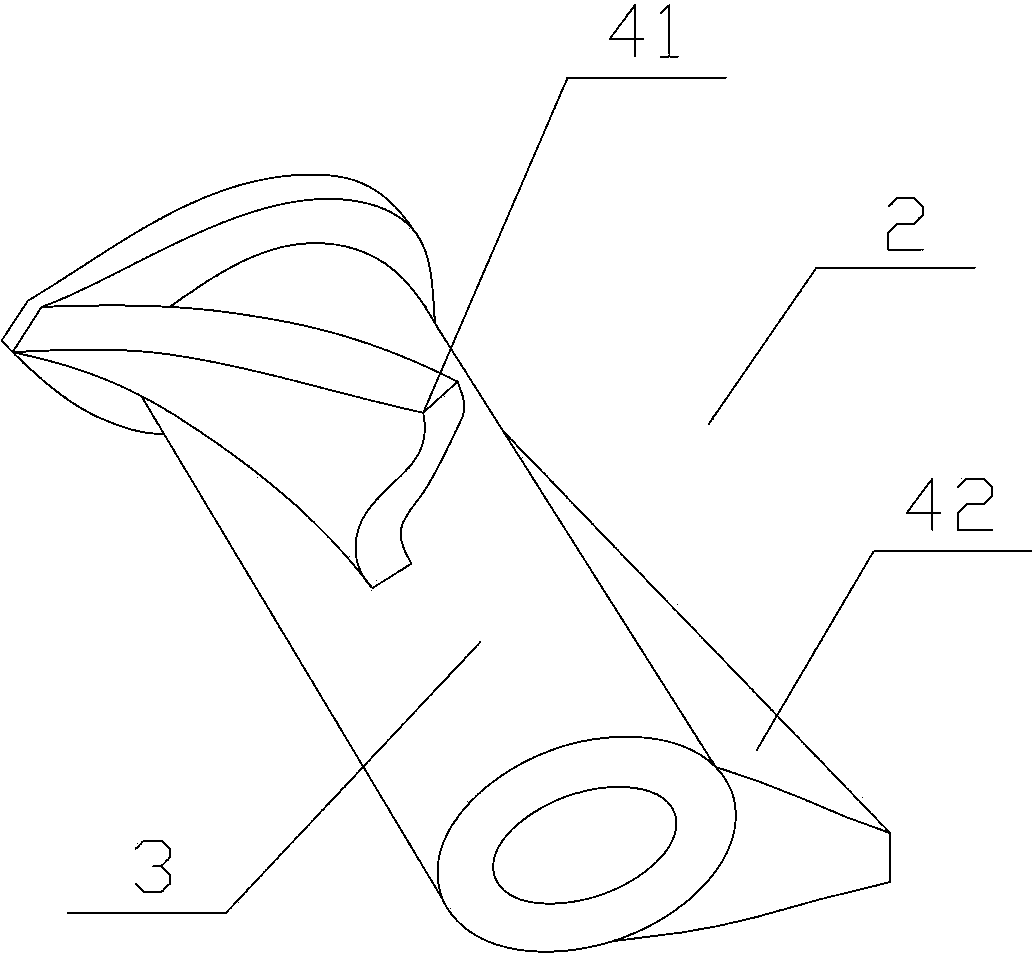

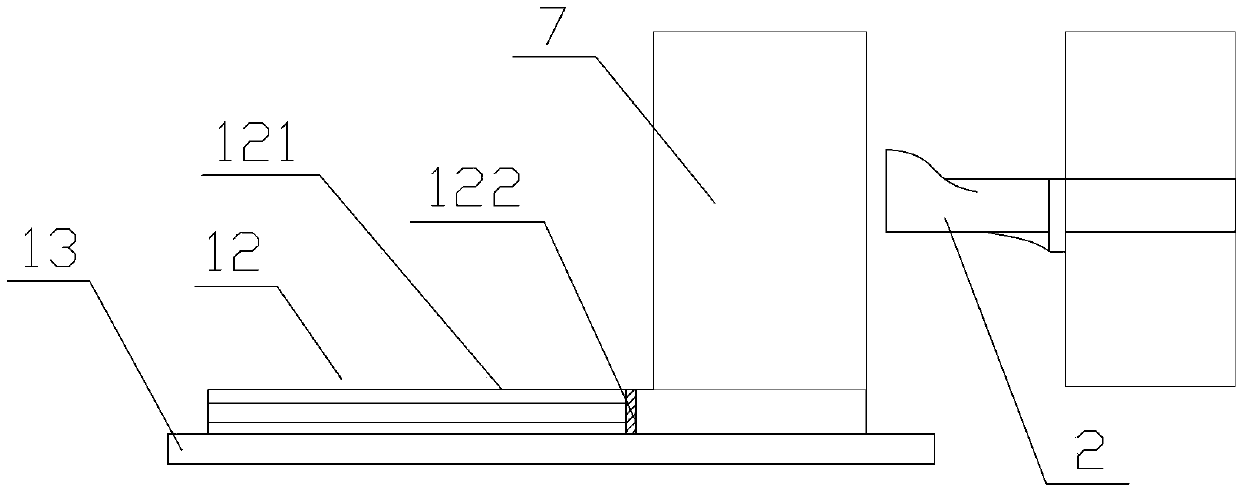

[0021] See figure 1 , figure 2 , Embodiment 1 of the present invention, a banburying device, comprising a banburying chamber 1 and two rotors 2 with the same shape and parallel to each other arranged in the banburying chamber 1; wherein, the rotor 2 includes a rotor body 3 and is arranged in the rotor There are two first helical ribs 41 and second helical ribs 42 with opposite helical directions on the surface of the body 3 . In the embodiment of the present invention, the turning direction of the two rotors 2 is opposite and the rotational speed is the same. Since the rotors 2 have helical ribs 4 arranged in the helical direction, and the rotational speeds of the two rotors 2 are the same, the relative speed of the helical ribs 4 of the two rotors 2 The position changes all the time, so that the capacity of the mixture of metal powder and binder between the two rotors 2 also changes all the time, so that the mixture is strongly stirred and kneaded.

[0022] In Embodiment 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com