A continuous jet descaling process for cold metal sheets and strips

A metal strip and jet technology, applied in metal processing equipment, metal rolling, metal rolling and other directions, can solve the problems of not cleaning the surface, low stabilization effect, and inability to effectively remove the embedded hard particles. Improve surface cleanliness and drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

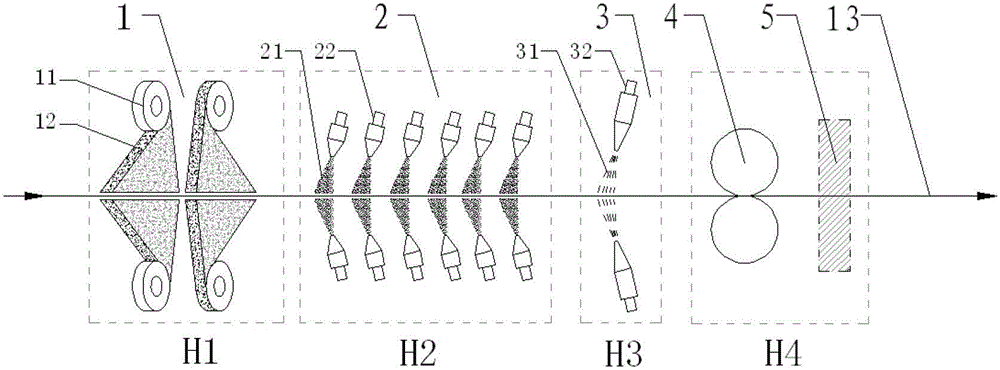

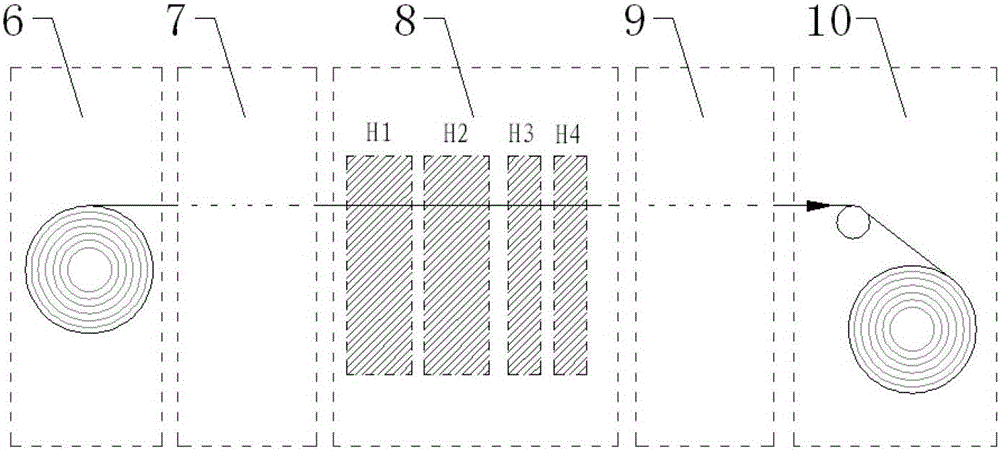

[0049] As mentioned above, the layout scheme of the new descaling process disclosed in this case is as follows: figure 2 As shown, in order to ensure that the new descaling process layout method disclosed in this case has a good effect, the following measures are mainly adopted:

[0050] 1) Centrifugal ejection pretreatment: use the centrifugal high-speed ejection of sand-like hard (abrasive) particles 12 to collide with the metal strip 13 to achieve scale pretreatment on the upper and lower surfaces of the metal strip 13;

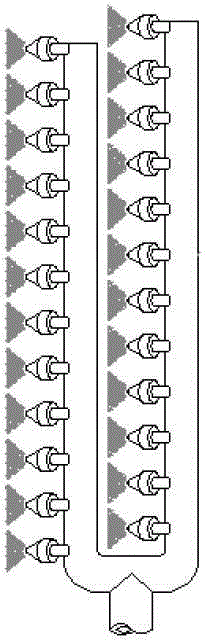

[0051] 2) Mixed jet descaling: The descaling nozzle 22 adopts a mixed jet nozzle, and its jet contains a large amount of fine sand-like hard particles (abrasives). The high-speed scouring function of the sand-like hard particles is used to clean the surface of the metal strip 13. Rapid removal of scales;

[0052] 3) High-pressure water washing: use densely arranged high-pressure pure water at a certain pressure to continuously clean and spray the board s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com