Composite cable guide inner pipe outer surface grooving machine

A composite cable and slotting machine technology, which is applied in metal processing and other directions, can solve the problems that the bonding force cannot meet the shear force and tear resistance requirements, the inner tube and the outer tube split and slip, and the promotion and use of unfavorable products, etc. , to achieve the effects of easy passing, avoiding stuck cables, and fast processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

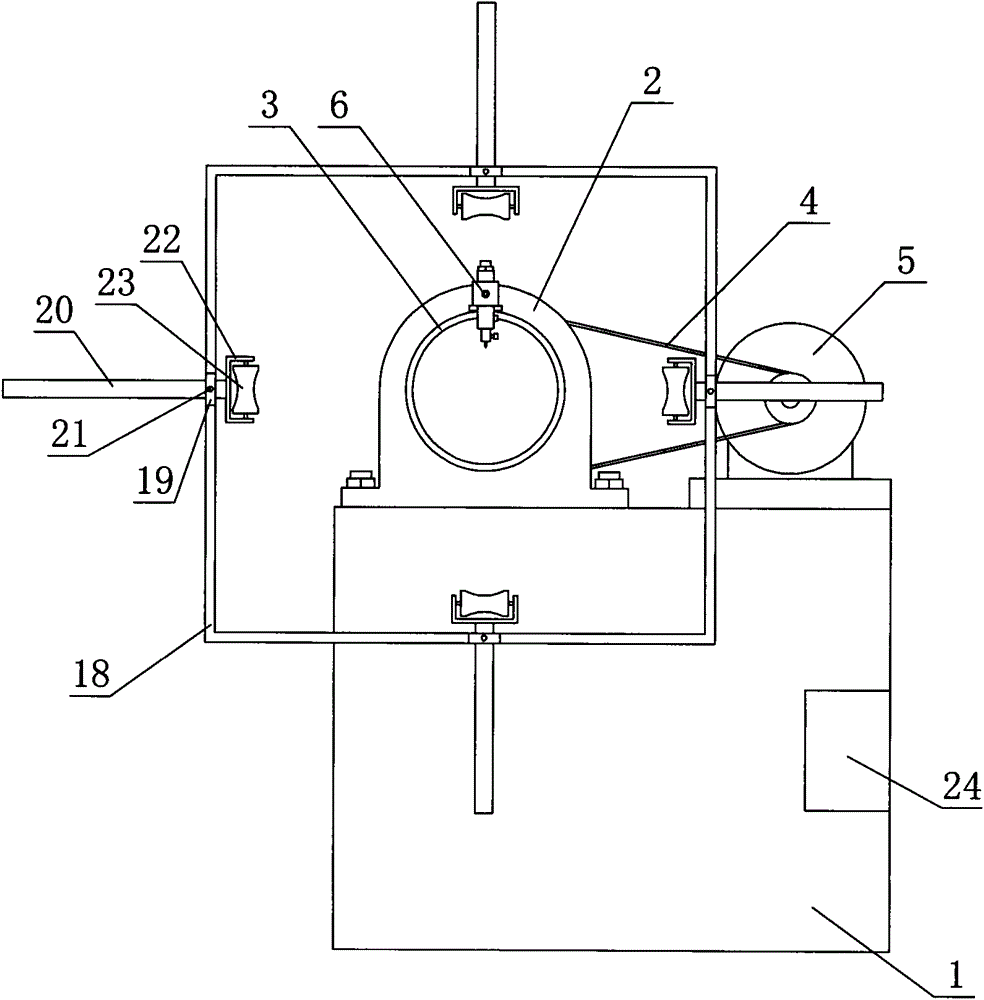

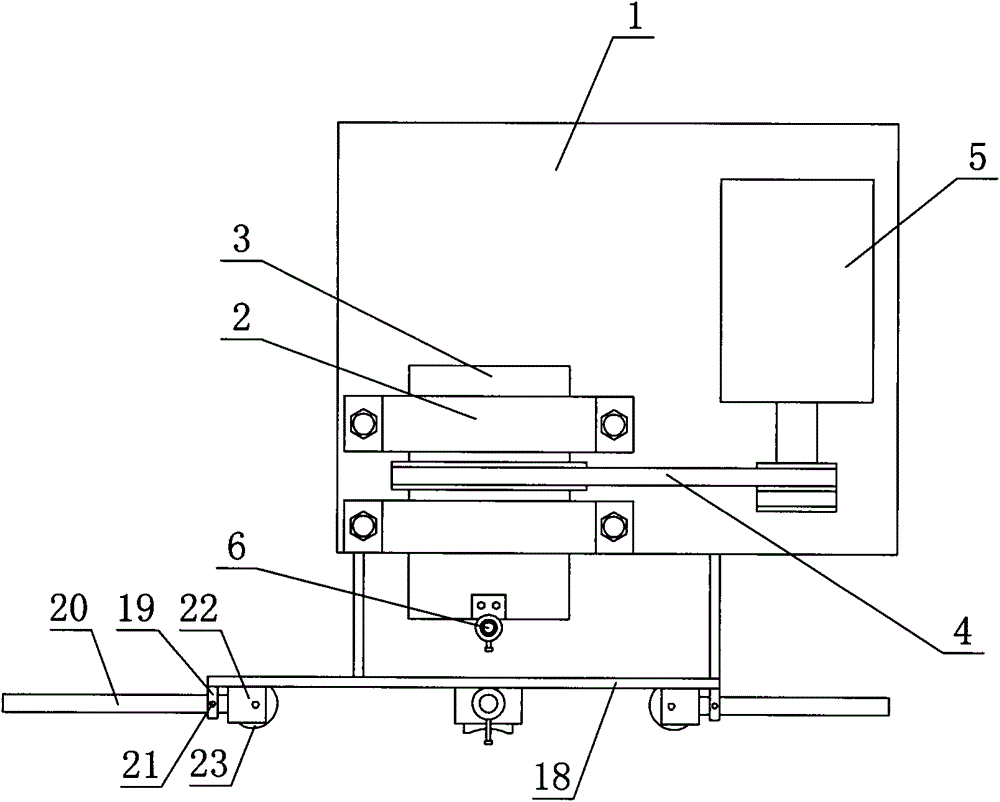

[0019] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

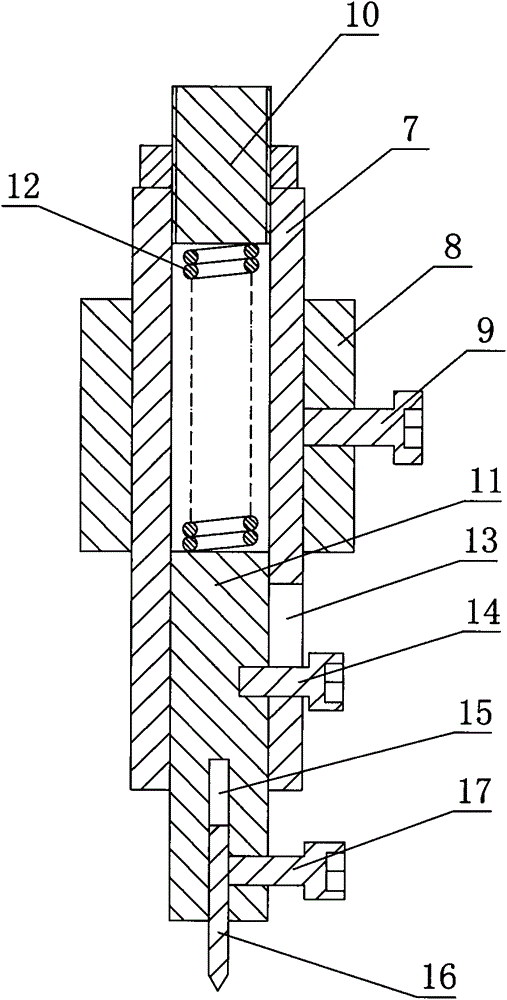

[0020] Such as Figure 1-3 As shown, a slotting machine for the outer surface of the inner tube of a composite cable conduit includes a frame 1, a processing sleeve 3 is installed on the frame 1 through a bearing seat 2, and a pulley located in the middle of the processing sleeve 3 passes through a transmission belt 4 and A pulley on the output shaft of the motor 5 on the frame 1 is connected, and one end of the processing sleeve 3 is provided with a slotting device 6 perpendicular to the axial direction of the processing sleeve 3 .

[0021] The slotting device 6 includes an inner tube body 7 arranged perpendicular to the axial direction of the processing sleeve 3 and an outer tube body 8 that is movably sleeved on the outside thereof and fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com