Automatic wood splicing machine

A kind of wood splicing machine and automatic technology, which is applied in the direction of wood processing equipment, wooden veneer joints, manufacturing tools, etc., can solve the problems of poor reliability of wooden strip transportation, wooden strips cannot be sent away, and low production efficiency, so as to improve the quality of wood Utilization rate, avoiding slippage, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

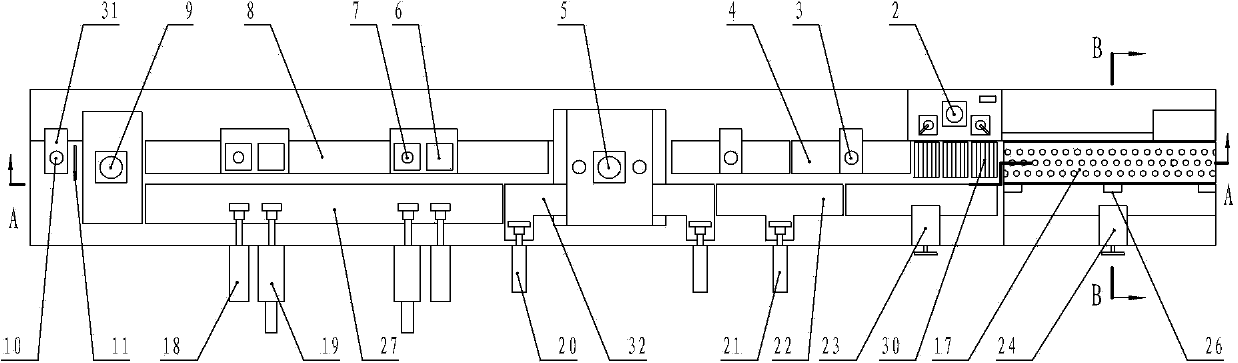

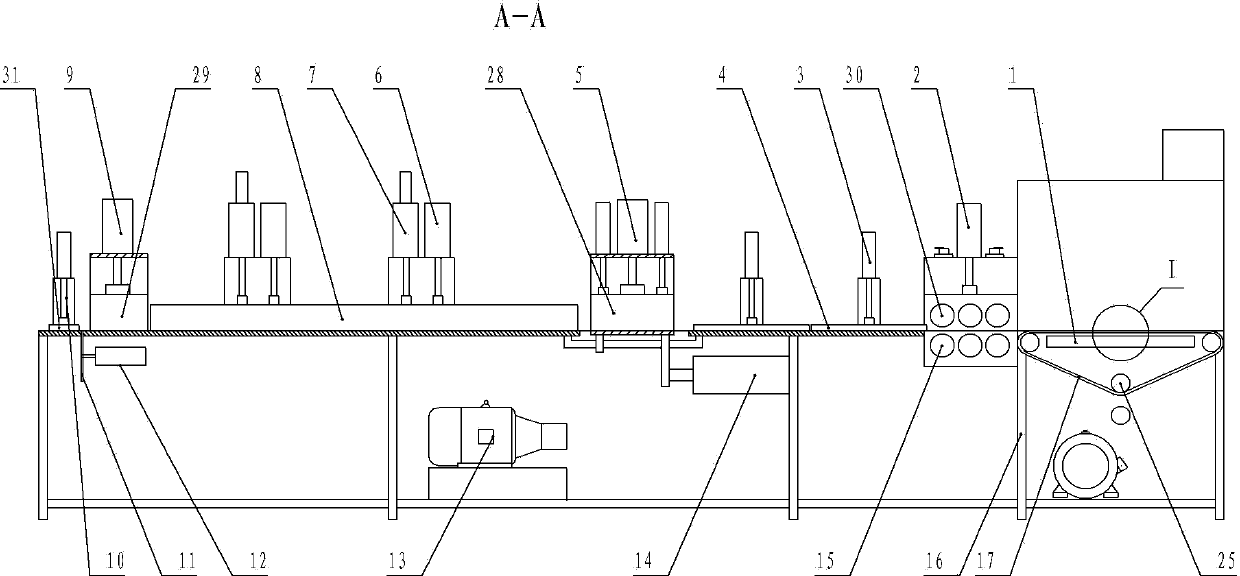

[0022] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

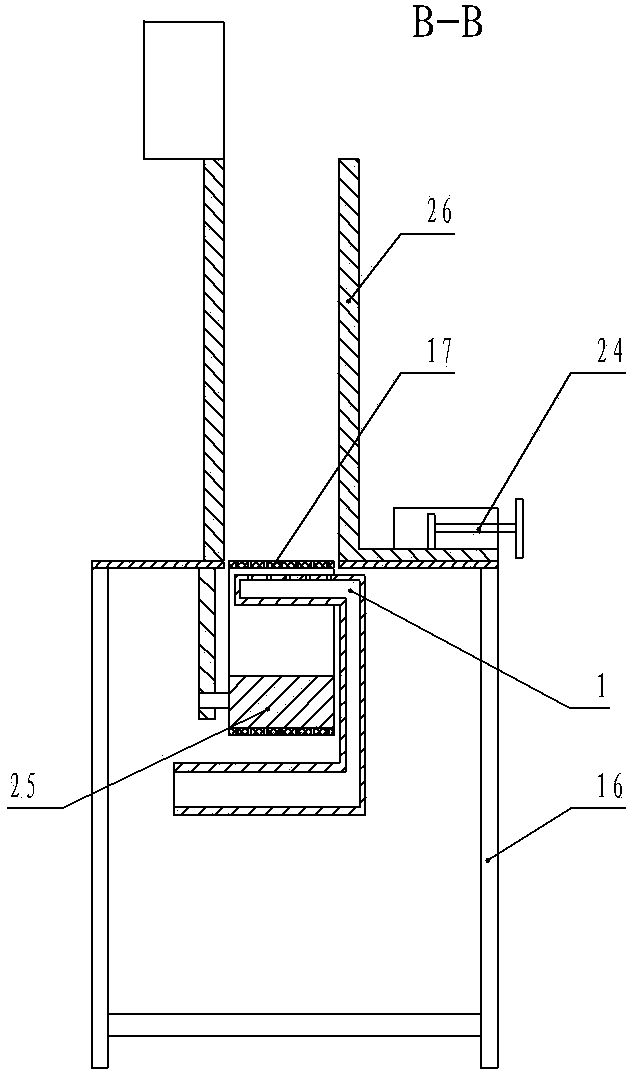

[0023] figure 1 , figure 2 and image 3 The automatic splicing machine of the present invention comprises a splicing platform arranged on the frame 16, on which there is a conveying channel for splicing short wooden strips one by one and extending forward; Material mechanism, pre-pressing device and extruding device and cutting device; Belt conveying device includes the conveying belt 17 that is sleeved on two belt pulleys and a belt tensioner 25; Belt is driven by motor; Figure 4 As shown, the conveyor belt 17 is provided with ventilation holes; a negative pressure adsorption device 1 is arranged under the feeding section of the belt 17, and the negative pressure adsorption device 1 is a square air duct with four walls sealed and a through hole on the top surface. , the through hole provided on the top surface of the air duct corresponds to the part of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com