Stacker crane with tray automatic recycling function

An automatic circulation and palletizer technology, which is applied in the stacking of objects, conveyors, conveyor objects, etc., can solve the problem that automatic palletizers do not have the function of automatic pallet recycling and recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

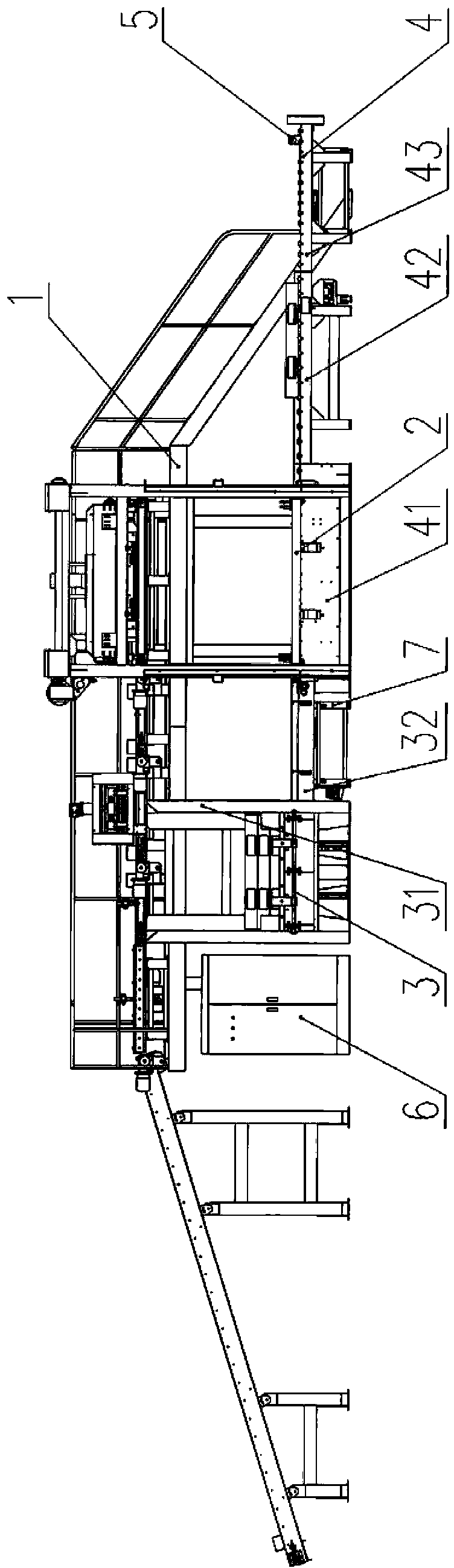

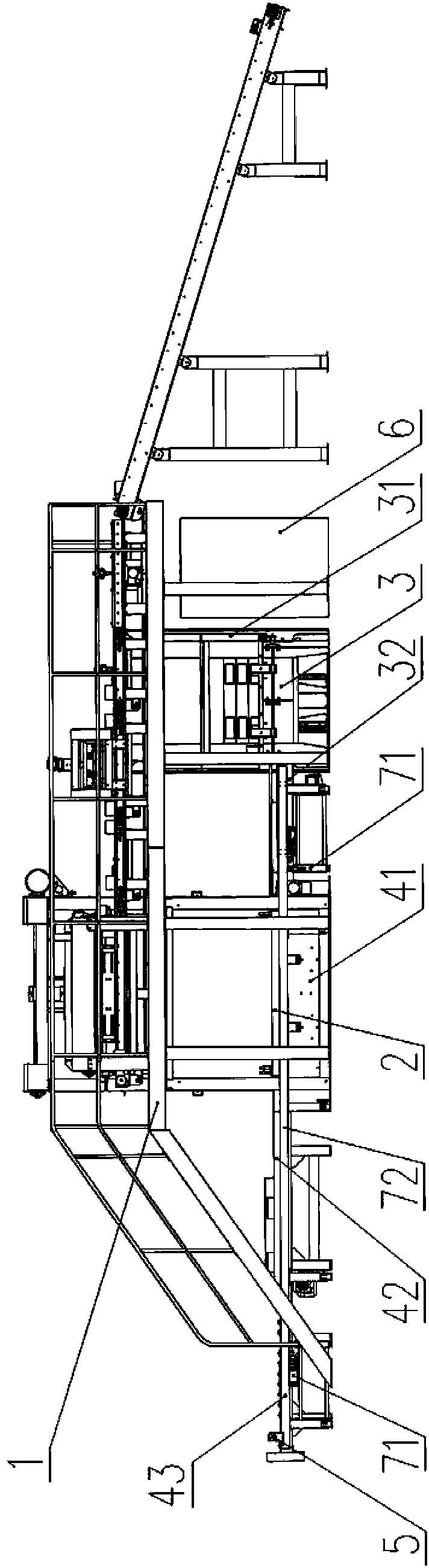

[0036] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a kind of palletizer with pallet automatic recycling function in the preferred embodiment of the present invention is mainly composed of elevated platform 1, elevator 2, unpacking machine 3, pallet conveyor 4, sensor 5, electric control cabinet 6, The pallet automatic circulation recovery device 7 is composed of; the lifter 2, the unpacking machine 3, and the pallet conveyor 4 are installed below the elevated platform 1; the pallet unpacking machine 3 is connected in a straight line with the pallet conveyor 4. It can also be connected vertically at 90 degrees; the pallet conveyor 4 is installed under the elevator 2; , the output end of the chain conveyor 32 is linearly connected to the front end of the pallet conveyor 4; the pallet conveyor 4 is the first roller conveyor installed in sequence from the rear end of the chain conveyor 32 of the dismantling machine 3 41. The second roller conveyor 42 and the ...

Embodiment 2

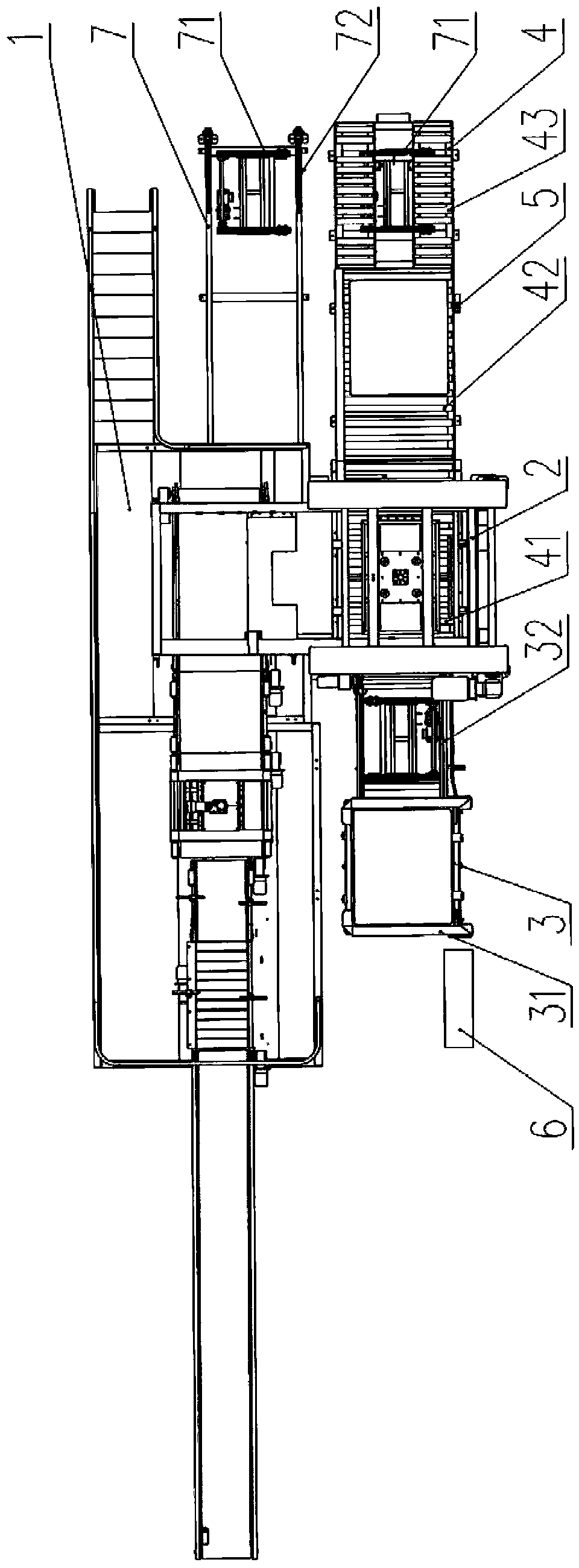

[0039] Such as Figure 5 , Figure 6 , Figure 7 As shown, a kind of palletizer with pallet automatic recycling function in the preferred embodiment of the present invention is mainly composed of elevated platform 1, elevator 2, unpacking machine 3, pallet conveyor 4, sensor 5, electric control cabinet 6, The pallet automatic recycling device 7 is composed of; the palletizer is a high-position double-line automatic palletizer; the lifter 2, the unpacking machine 3, and the pallet conveyor 4 are installed below the elevated platform 1; the palletizing machine 3 It is connected vertically at 90 degrees to the pallet conveyor 4, and in another embodiment, it can also be a straight connection; the pallet conveyor 4 is installed below the elevator 2; Machine 32 is made up of, and chain conveyor 32 is installed in the below of tray storehouse 31, and the output end of chain conveyor 32 is vertically connected on the front end side of pallet conveyor 4; The first roller conveyor 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com