Polycaprolactam composite material and preparation method thereof

A technology of polycaprolactam and composite materials, which is applied in the field of polycaprolactam composite materials and its preparation, to achieve the effect of high gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

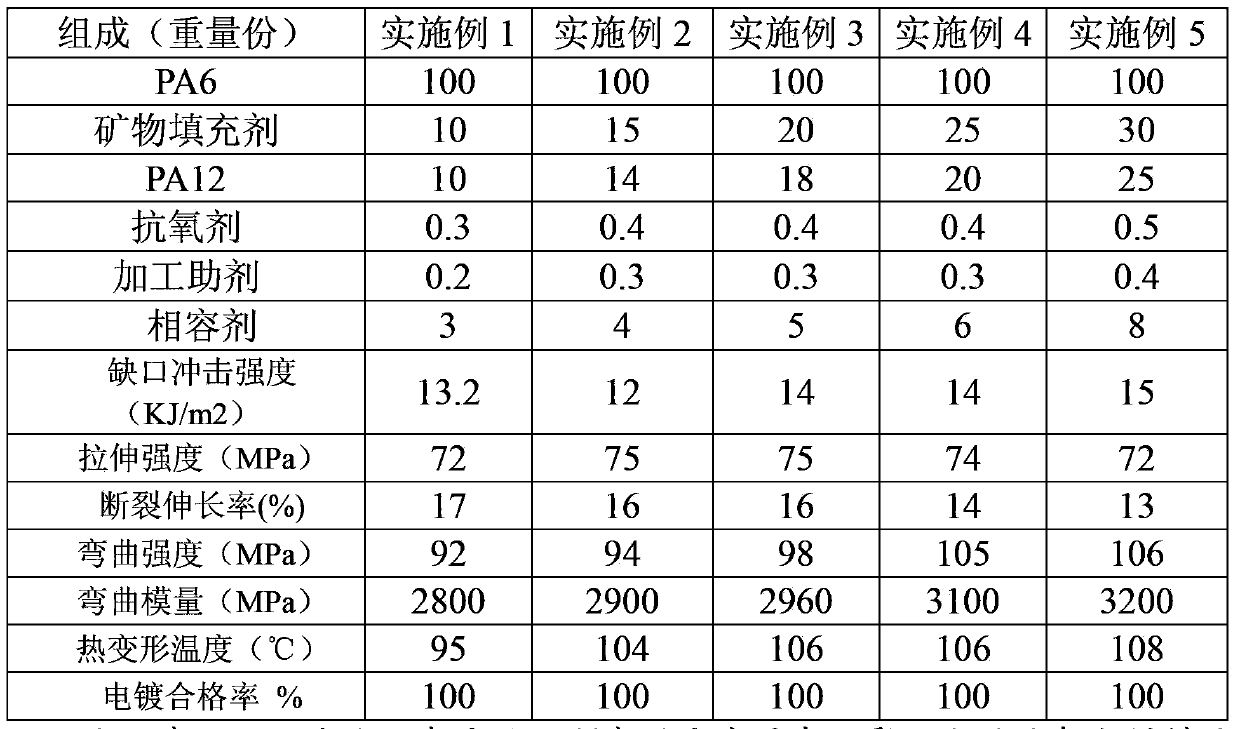

Examples

preparation example Construction

[0022] The embodiment of the present invention also provides a preparation method of the above-mentioned polycaprolactam composite material. The method includes the following steps: weighing polycaprolactam 100, mineral filler 10-30, polylaurolactam 10-25, anti- Oxygen agent 0.3-0.5 and compatibilizer 3-8, and mix uniformly; melt and extrude the uniformly mixed material, and granulate. Wherein, when the polycaprolactam, the mineral filler, the polylaurolactam, the antioxidant and the compatibilizer are mixed, a processing aid is also added, which is 0.2-0.4 in parts by weight. The polycaprolactam, mineral filler, polylaurolactam, antioxidant, processing aid and compatibilizer are mixed at high speed for 10 to 15 minutes to make them uniform; the uniformly mixed materials are extruded by twin-screw Melt extrusion and granulation; the working parameters of the twin-screw extruder are: the temperature of the first zone is 210-230°C, the temperature of the second zone is 230-260°C...

Embodiment 1

[0027] The polycaprolactam composite material provided by the embodiment of the present invention comprises the following components in parts by weight: polycaprolactam PA6100, mineral filler 10, polylaurolactam PA1210, antioxidant 0.3, processing aid 0.2, compatibilizer 3.

[0028] The preparation method of the polycaprolactam composite material provided by the embodiment of the present invention comprises the following steps: take polycaprolactam, mineral filler, polylaurolactam, antioxidant, processing aid and compatibilizer according to the above parts by weight, and then Mix in a high-speed mixer for 10 minutes, then extrude through a twin-screw extruder and granulate. The working parameters of the twin-screw extruder are: the temperature of the first zone is 210-230°C, the temperature of the second zone is 230-260°C, the temperature of the third zone is 240-265°C, the temperature of the fourth zone is 235-250°C, the temperature of the fifth zone is The temperature is 24...

Embodiment 2

[0030] The polycaprolactam composite material provided by the embodiment of the present invention comprises the following components in parts by weight: polycaprolactam PA6100, mineral filler 15, polylaurolactam PA1214, antioxidant 0.4, processing aid 0.3, compatibilizer 4.

[0031] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com