Thread clamping adjustment knob of sewing machine

A sewing machine and knob technology, which is applied to sewing machine components, sewing equipment, tension devices, etc., can solve the problems of increased manufacturing cost, screw damage, and small size of positioning buttons and other components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

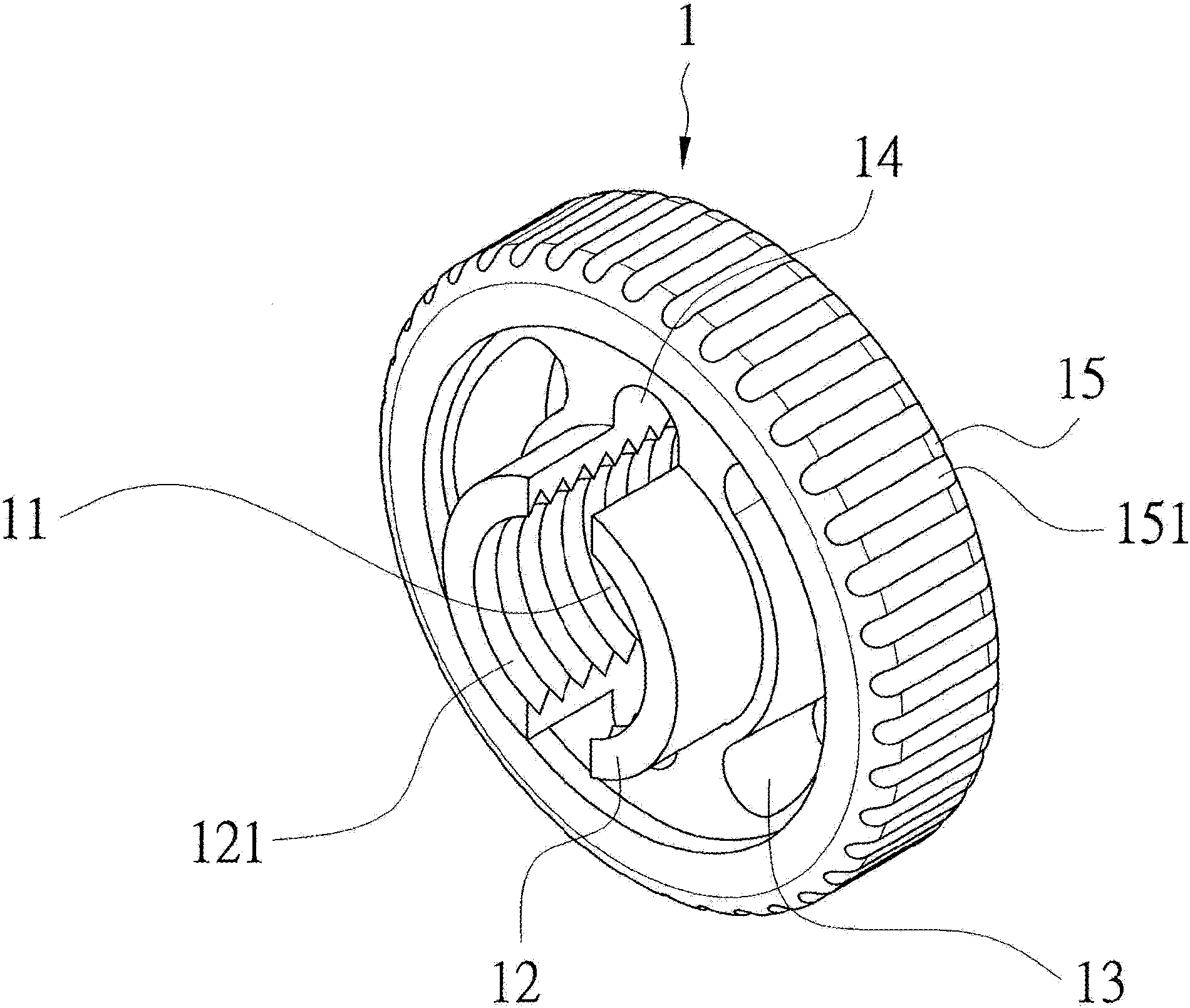

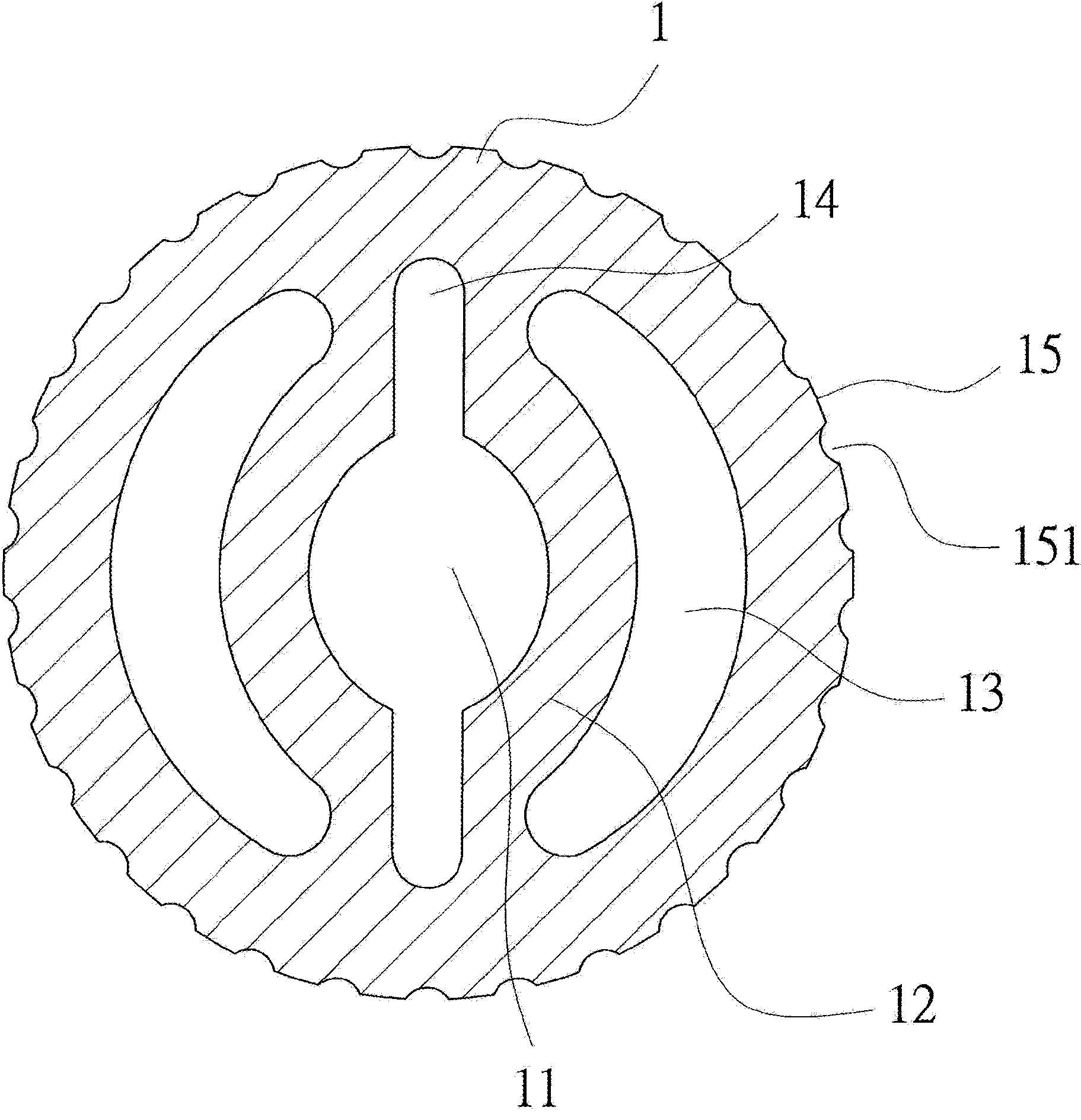

[0030] First, see figure 1 The three-dimensional structure diagram of the present invention shown and figure 2 As shown in the cross-sectional structure diagram of the present invention, the present invention is mainly provided with a knob 1 which is provided with a screw portion 12 formed around and surrounded by the corresponding central through hole 11, and the screw portion 12 corresponds to The inner surface of the through hole 11 is provided with a thread 121, and the outer periphery of the screw portion 12 is provided with an elastic slot 13; a slot 14 is formed between the two screw portions 12, and is formed on the surface of the outer ring portion 15 on the outer edge of the knob 1. There is a recess 151.

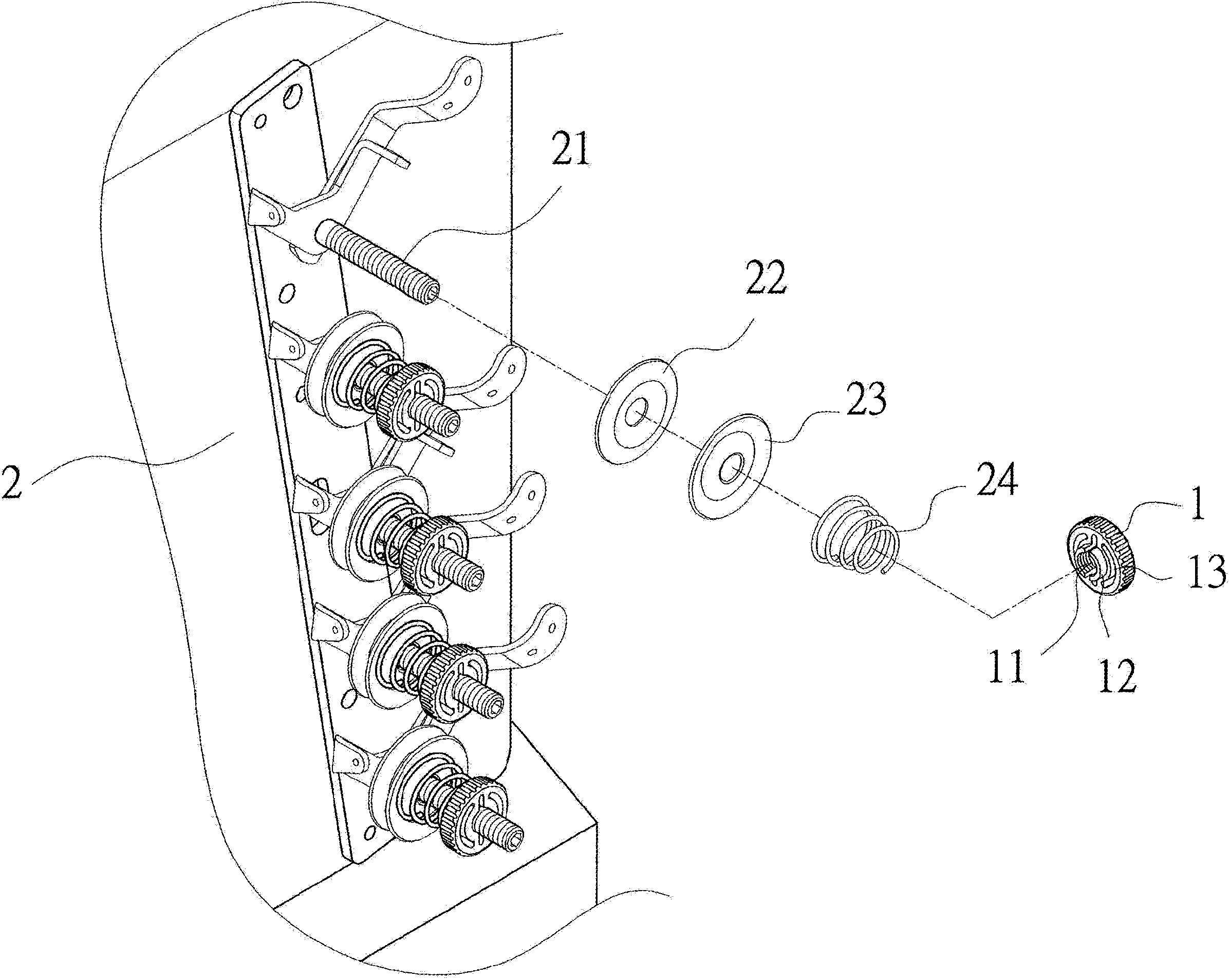

[0031] Therefore, please refer to the operation and use of the present invention image 3 As shown in the three-dimensional exploded state diagram of the present invention, the screw 21 of the sewing machine table 2 can be respectively sheathed with an inner clip 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com