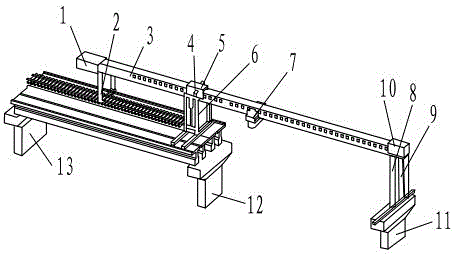

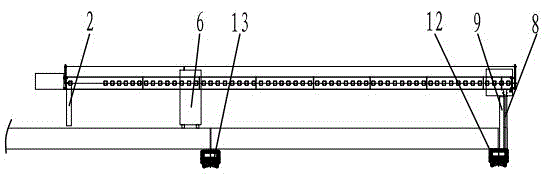

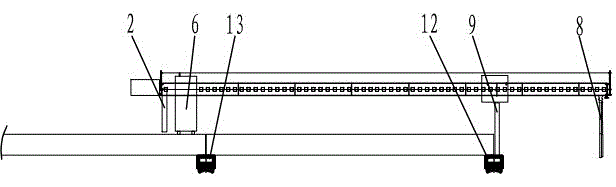

DJ180 Bridge Erecting Machine Erecting Method of Passing Hole of Box Girder of Long-span Highway

A technology of 1.DJ180, bridge erection machine, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems of small span and inability to apply, and achieve the effects of excellent performance, convenient transportation and assembly, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

[0074] There are 16 girders in a railway bridge project on the Jiexi Line in a certain city, with a span of 40 meters and a maximum weight of 168 tons. In July 2012, the erection of all girders was successfully completed using the DJ180 bridge erecting machine.

example 2

[0076] About 300 meters to the west of a certain bridge, spanning the flood discharge channel of Yongding River, it is divided into two parts, the main road bridge and the south auxiliary road bridge, with a total length of 105 meters. The main road bridge is: 30m+40m+30 (8 pieces per hole) simply supported small box girder. The auxiliary road bridge is: 30m+40m+30m (4 pieces per hole) simply supported small box girder structure. Among them, the 30m prefabricated box girder is 30m long, 2.5m wide, 1.5m high and weighs 101 tons. 40m prefabricated box girder: 40.5m long, 2.5m wide, 1.9m high, and weighs 159 tons. In May 2012, the erection of all girders was successfully completed using the DJ180 bridge erecting machine.

[0077] The benefit analysis of the present invention in actual use:

[0078] The main road of an industrial park spans the overpass of Jiexi Line. The total length of the bridge is 95.3 meters, the span of the bridge is 40 meters, and the maximum weight of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com