Plugging, regulating and washing process of oil well

A technology of oil wells and processes, which is applied in wellbore/well components, production fluids, earthwork drilling and production, etc. It can solve the problems of inability to improve oil production efficiency, retention, and inability to be displaced, and achieve the improvement of potential tapping effect and reservoir The effect of increased mobilization and strengthened governance measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

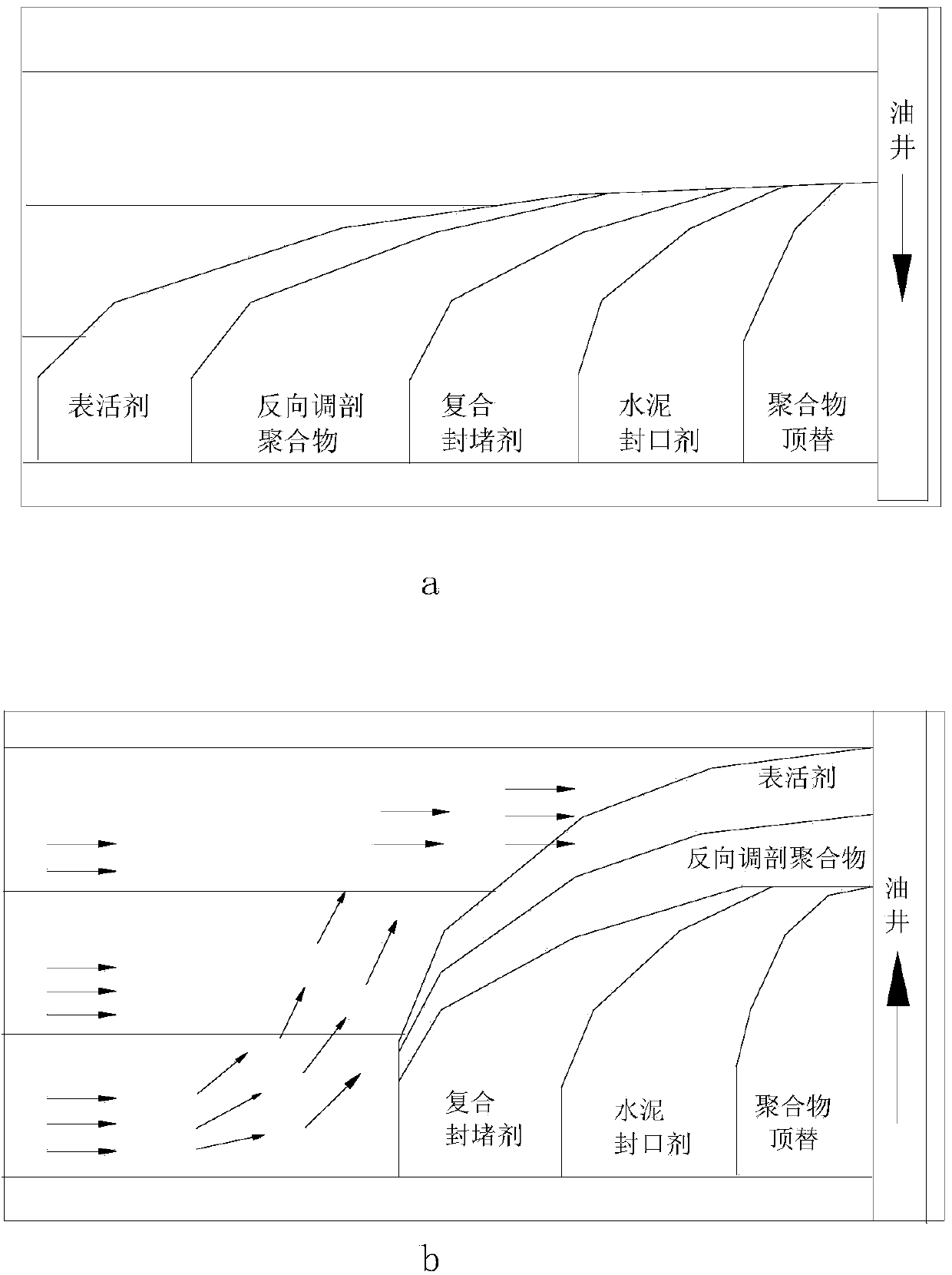

[0010] The present invention will be further described below in conjunction with accompanying drawing:

[0011] The oil well plugging, adjusting and washing process technology is to inject a surfactant solution slug and a reverse profile control polymer solution slug before the composite plugging agent slug, and through the plugging, adjusting and washing three technologies on the oil well A process method of comprehensive application, which expands the swept volume of water injected at the well end, reduces the comprehensive water cut at the oil well end, improves the oil washing efficiency, fully excavates the remaining oil in the formation, and improves the recovery factor.

[0012] It specifically includes the following processes: 1. Pre-slug injection: The agents used in this slug are surfactant solution and reverse profile control polymer. The remaining oil is then injected into the reverse profile control polymer. Since the viscosity of the reverse profile control polym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com