Full-height roof support method in ultra-thick coal seam mining

A technology of extra-thick coal seam and roof support, which is applied in special mining, surface mining, mining equipment and other directions, can solve the problems of unsatisfactory coal seam occurrence blocks, inability to recover and re-mining, and unsuitable working face for mining. The effect of eradicating hidden dangers of spontaneous combustion, increasing safe exits, and improving disaster resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

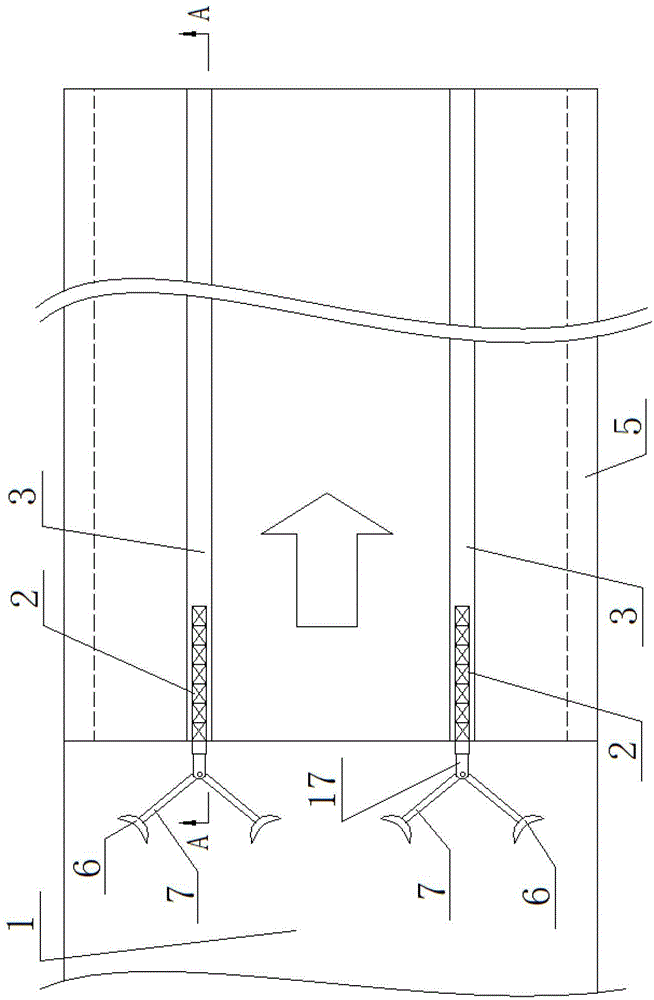

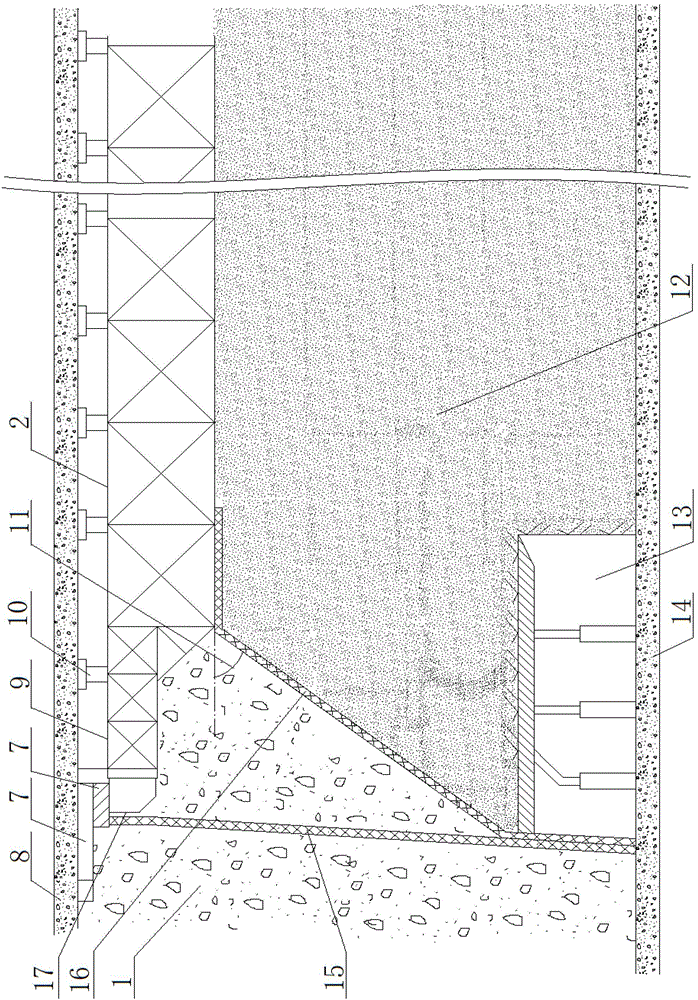

[0035] Such as figure 1 and figure 2 As shown, the extra-thick coal seam adopts a full-height roof support method, including excavating a roof roadway 3, installing a frame beam cantilever support 2, installing a protective net 15, mining the top coal seam of an extra-thick coal seam under the cantilever 9, and installing a supporting roof net 16, Excavating the light support working face 13, implementing the top coal caving on the light support working face, and transporting the top coal; it is characterized in that the specific steps of the method are as follows:

[0036] (1) Excavating roof roadway 3

[0037] At the edge of the mining area at the top of the coal seam, at a distance of 15 meters in the transverse direction, excavate two roof roadways 3 suitable for the cross-section of the cantilever support of the frame beam;

[0038] (2) Install frame beam cantilever bracket 2

[0039] The frame beam cantilever support 2 is transported into the roof roadway 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com