Automotive hydraulic vane pump motor and switching control hydraulic system thereof

A technology of a hydraulic system and a vane pump, applied in the field of hydraulic pumps, can solve the problems of complex structure of the pump motor, difficult switching, difficult control, etc., and achieve the effects of avoiding the reduction of volumetric efficiency, simple structure and flexible vane control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

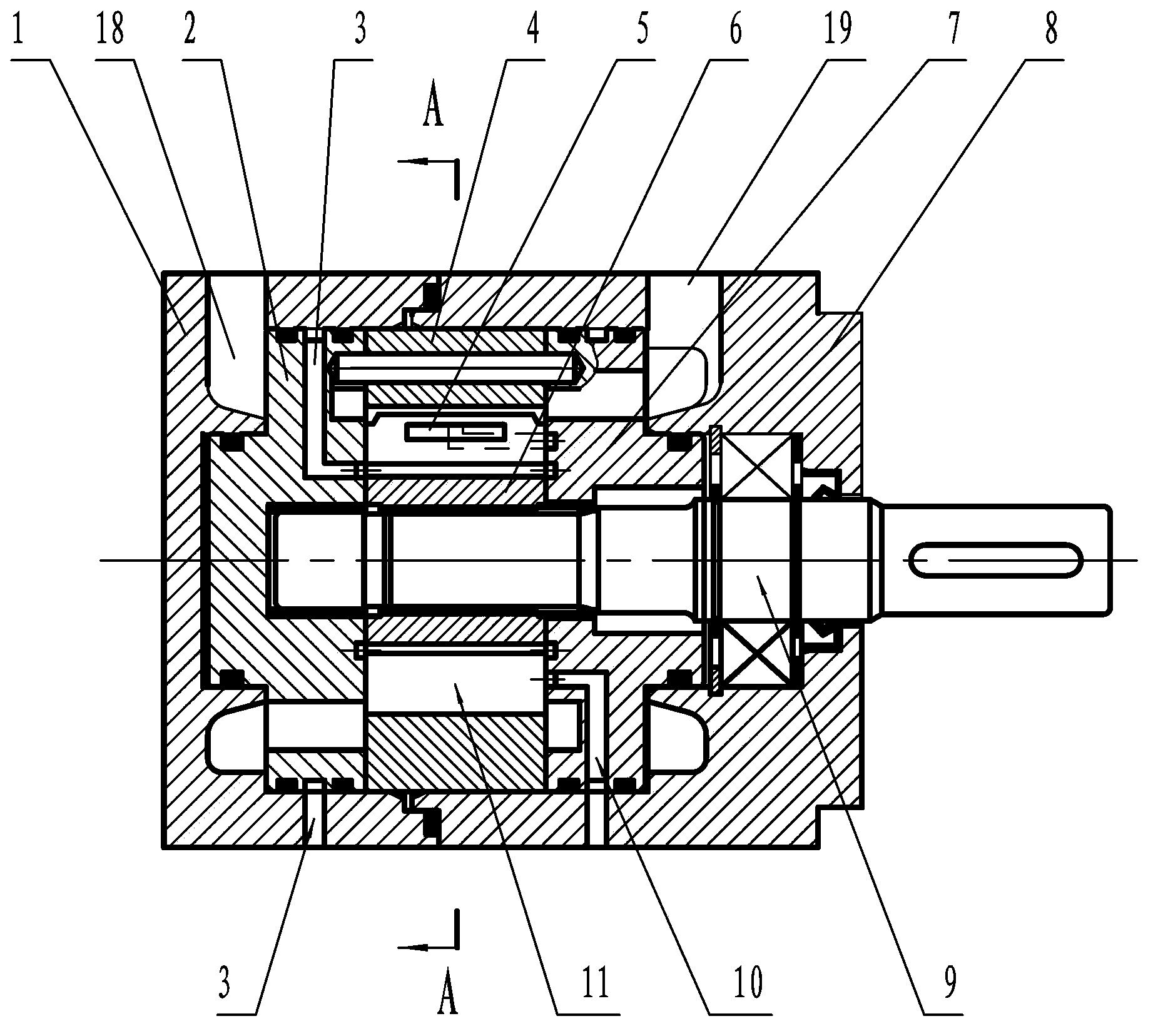

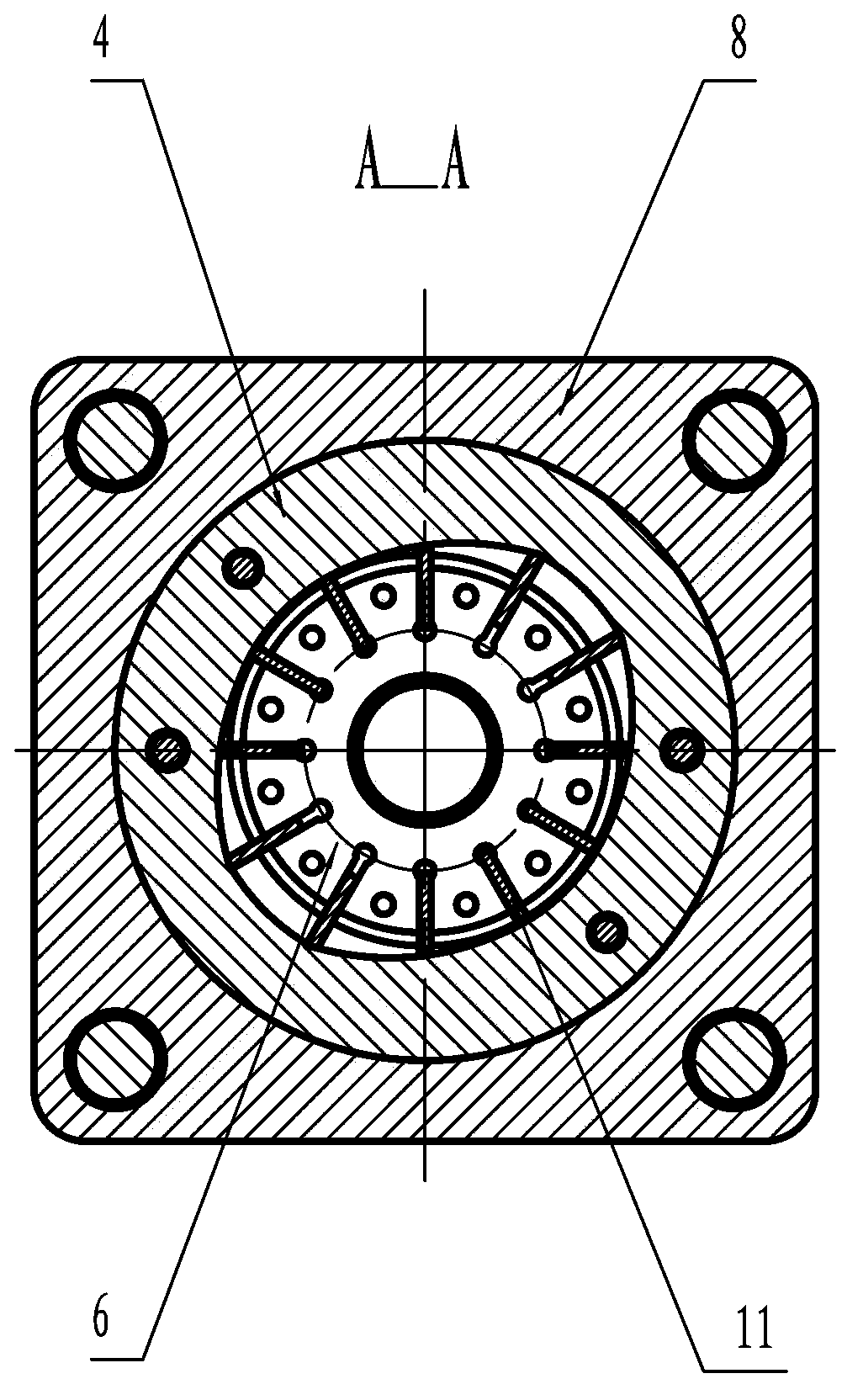

[0025] Embodiment 1: Vehicle hydraulic vane pump motor, as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 As shown, it includes rear pump cover 1, oil inlet oil distribution plate 2, stator 4, rotor 6, oil outlet oil distribution plate 7, front pump cover 8, shaft 9, blade 11, oil inlet 19 and oil outlet 18 .

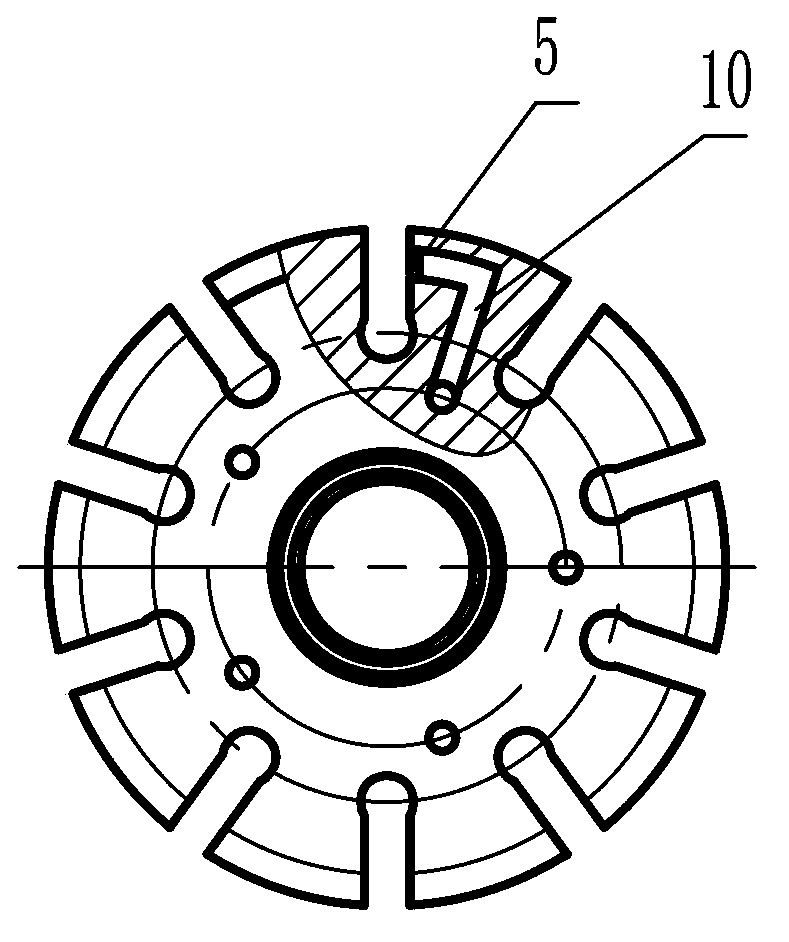

[0026] A hydrostatic oil chamber 5 is provided on the side wall of the vane groove on the rotor 6, and the hydrostatic oil chamber 5 communicates with an external hydraulic source through a signal oil channel 10; When extended to the maximum position and the minimum position, the openings of the static pressure oil chamber 5 are all facing the body of the blade 11 . The hydrostatic oil chamber 5 is an elongated groove, and the distances between the two ends of the groove and the side walls of the corresponding rotor 6 are equal.

[0027] The signal oil channel 10 is a three-stage structure, the first section is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com