A two-stage energy-saving air compressor with adjustable pressure ratio

An air compressor and compressed air technology, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems of efficiency loss, poor adjustment flexibility, large confirmation changes, etc., and achieve the goal of improving volumetric efficiency and increasing use efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

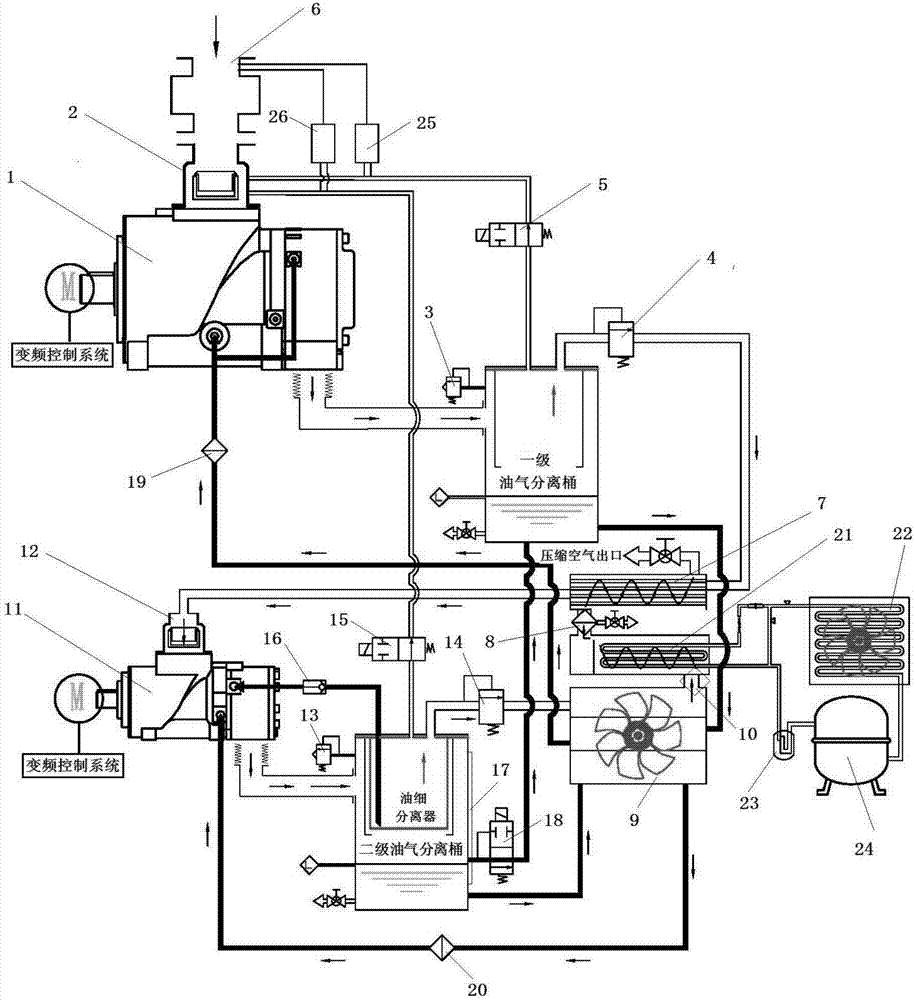

[0030] like figure 1 As shown, the present invention is a two-stage energy-saving air compressor with adjustable pressure ratio, which is a two-stage energy-saving air compressor unit with adjustable pressure ratio, oil-gas separation and air cooling between stages; it includes a primary compressor 1 and two-stage compression host 11, with an oil-gas separation barrel behind the second-stage compression main engine, that is, a second-stage oil-gas separation barrel, and an oil-gas separator is arranged in the second-stage oil-gas separation barrel; The oil-gas separation barrel is the first-stage oil-gas separation barrel; the two-stage compression hosts are directly connected by a coupling; each stage of compression host has its own frequency conversion control system; The exhaust pressure is reasonably distributed to the speeds of the compressor hosts at all levels. The speeds of the compressor hosts at all levels are fed back by pressure sensors at all levels and controlled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com