Direct injection valve structure in gas cylinder

An injection valve and gas cylinder technology, applied in the direction of internal combustion piston engine, charging system, combustion engine, etc., can solve problems such as volumetric efficiency loss, and achieve the effect of solving volumetric efficiency loss, high load, and large injection cone angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

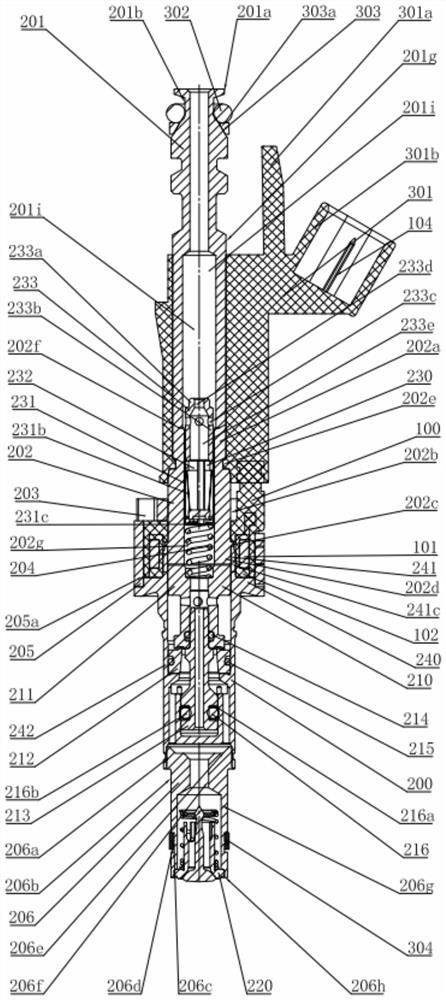

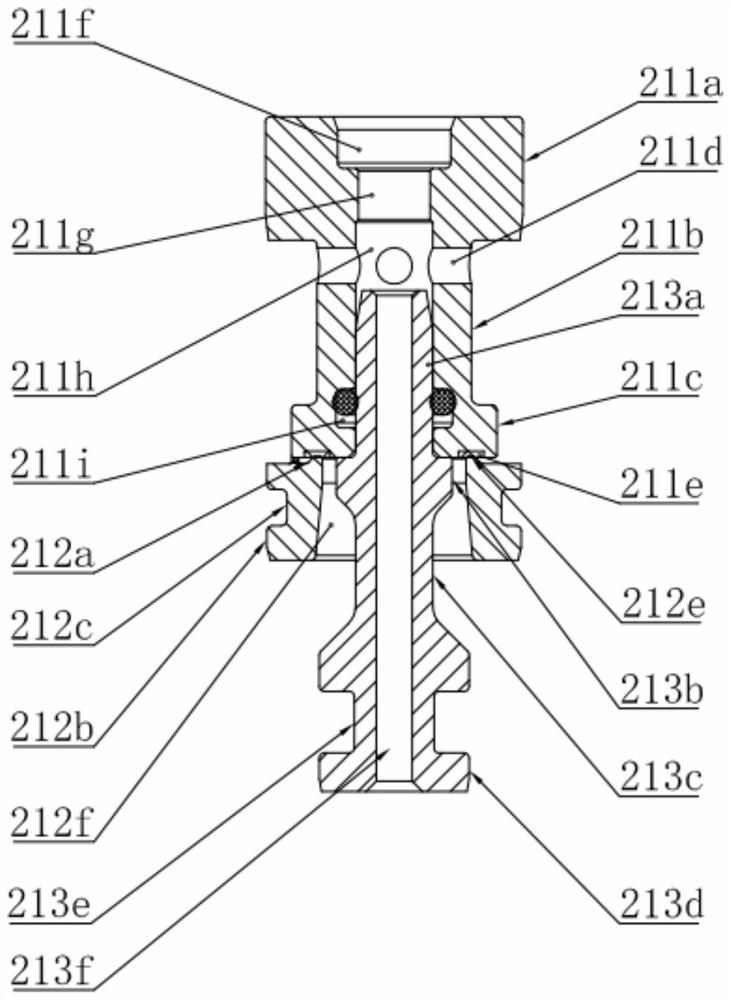

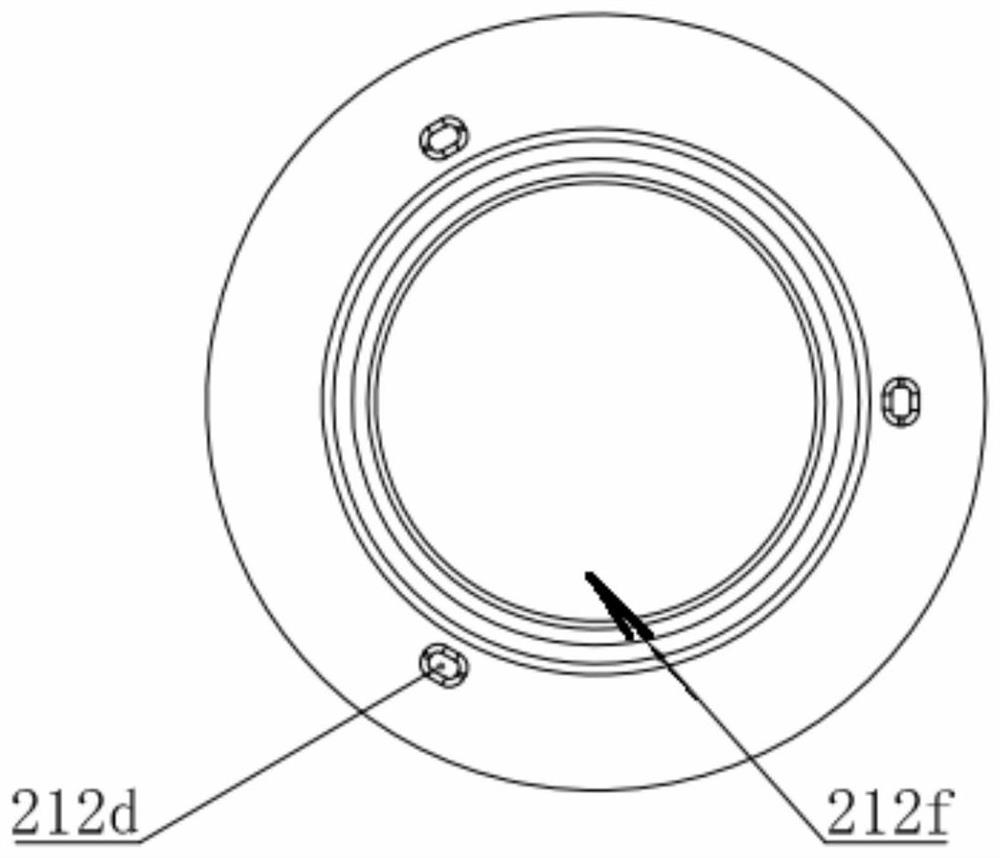

[0029] Structure of the present invention, further concrete description is as follows in conjunction with accompanying drawing:

[0030] see Figure 1 to Figure 7 , the gas in-cylinder direct injection valve structure shown in the figure includes: electromagnet component assembly 100, nozzle component assembly 200, and the specific technical scheme is as follows:

[0031] The nozzle part assembly 200 includes: an air inlet joint part, a nozzle body part 240 and an injection valve part 220 .

[0032] The intake joint part includes an intake joint 201, an iron core 202 and an intake valve assembly 230. An air intake hole axially penetrating the entire intake joint 201 is arranged in the intake joint 201, and a second A rod segment 201g, a first hole segment 201i is provided at the lower part of the air intake hole.

[0033] The iron core 202 is made of a magnetically permeable material, and its outer circumference is sequentially provided with a second rod segment 202a, a thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com