an intake pre-swirler

An air intake pre-swirler and pre-swirler technology, which is applied to machines/engines, components of pumping devices for elastic fluids, non-variable-capacity pumps, etc., can solve the design difficulty and adjustment of flow control control systems The blade opening cannot be zero, flow deviation and other problems, so as to avoid energy loss, improve stiffness, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

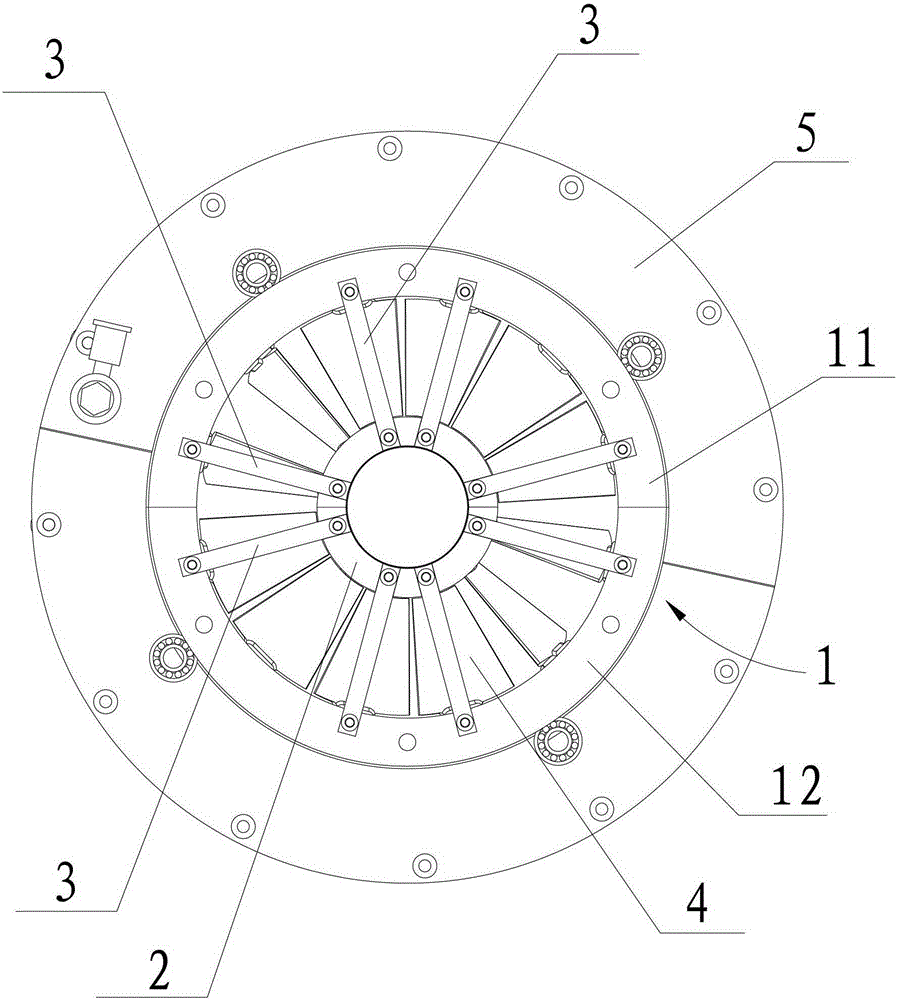

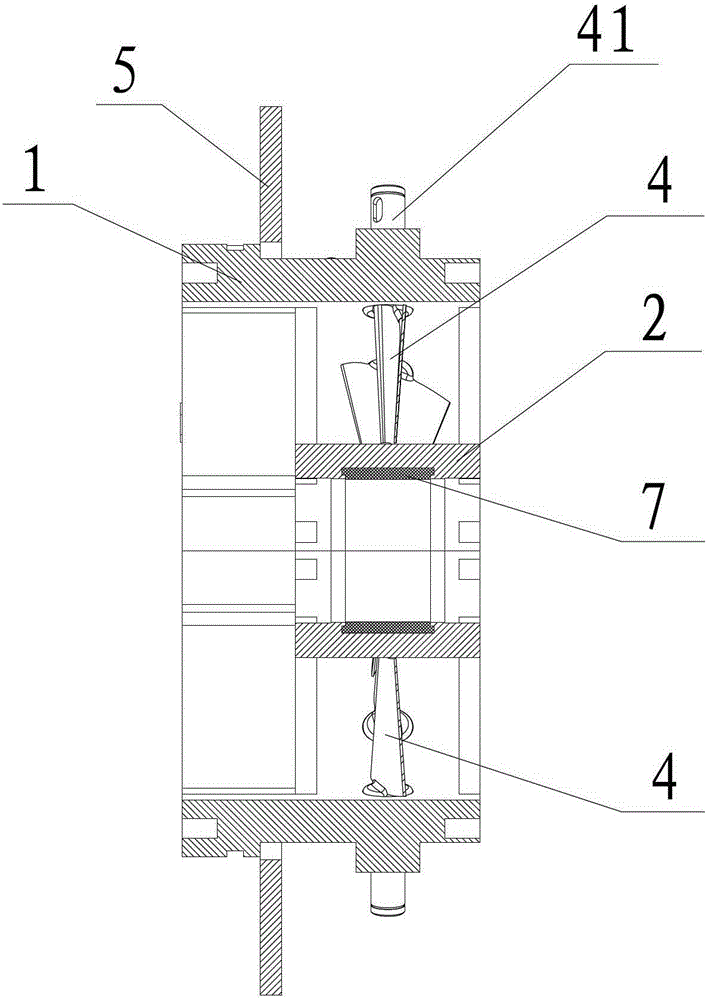

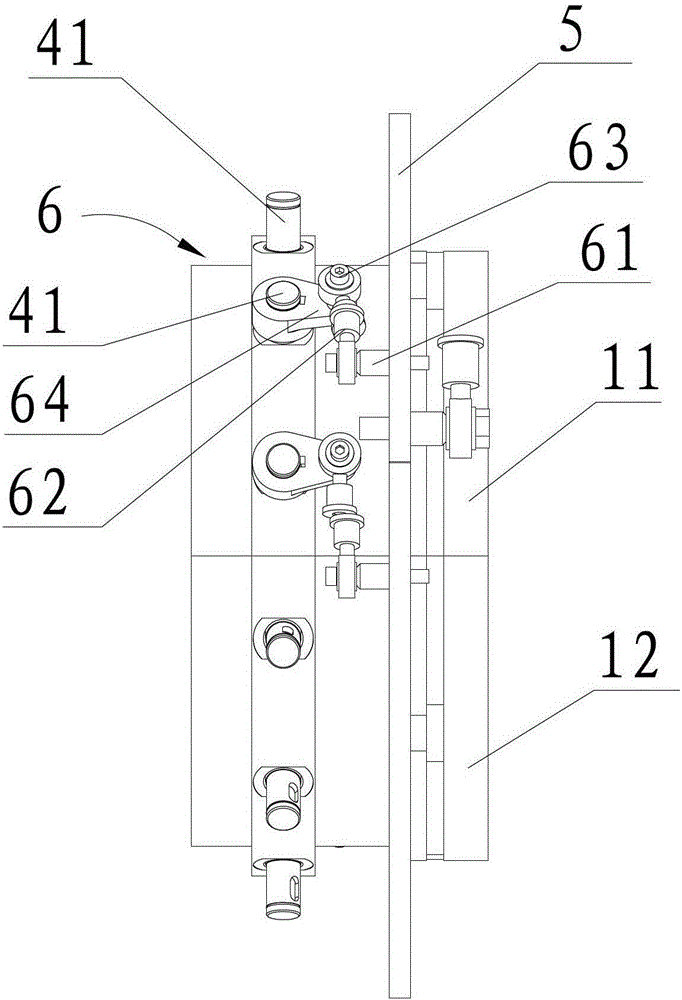

[0019] see Figure 1~4 The air intake pre-rotator shown in the figure includes a fixed outer ring 1 and a fixed inner ring 2. The fixed outer ring 1 has a hollow inner cavity and its two axial ends pass through each other. The two axial ends of the fixed outer ring 1 The ends are respectively used as the air inlet and the air outlet of the pre-rotator. The two shaft ends of the fixed inner ring 2 are sealed. The fixed inner ring 2 is coaxially arranged in the inner cavity of the fixed outer ring 1. The fixed inner ring 2 and the fixed outer ring 1 are fixedly connected by a plurality of connecting rods 3. The multiple The connecting rods 3 are distributed in the circumferential direction of the fixed outer ring 1 and the fixed inner ring 2 at intervals.

[0020] see Figure 1~4 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com