Pneumatic three-way diaphragm valve for explosive flow control

A three-way diaphragm valve and flow control technology, applied in the direction of diaphragm valve, diaphragm, multi-way valve, etc., can solve the problems of poor safety and low manual efficiency of the valve, and achieve the effect of excellent safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention are provided below, and it should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the scope of protection of the present invention.

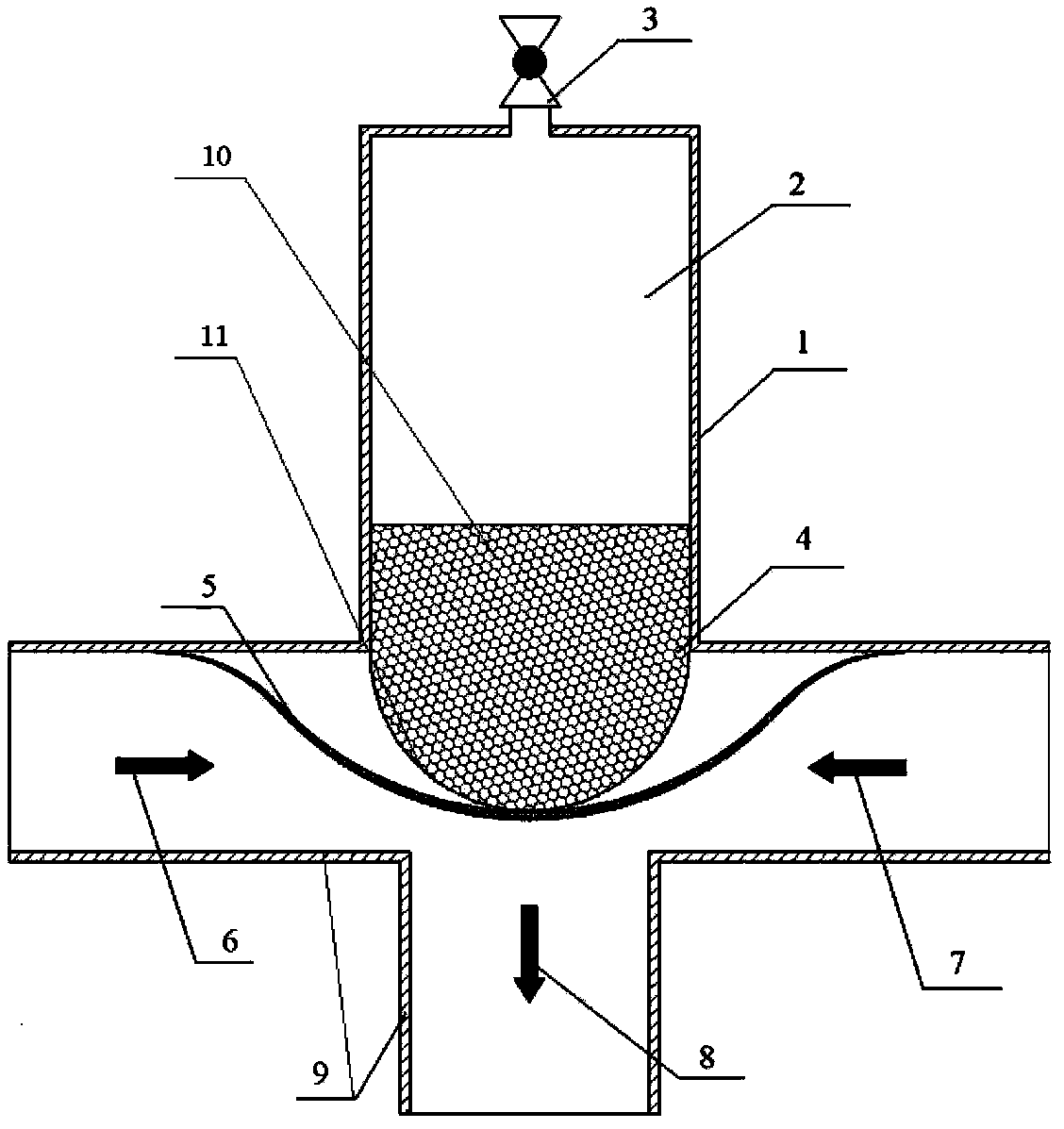

[0020] Comply with the above technical solutions, such as figure 1 As shown, a pneumatic three-way diaphragm valve used for explosive flow control includes a three-way pipe 9, and the three-way pipe 9 includes a first feed port 6, a second feed port 7 and a discharge port communicated with each other. Port 8, the first feed port 6 and the second feed port 7 are equidiametrically coaxial, and the discharge port 8 is perpendicular to the first feed port 6 and the second feed port 7 respectively;

[0021] The pneumatic three-way diaphragm valve also includes a cylinder block 1, the cylinder block 1 is connected to the three-way pipe 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com