Olive-shaped differential pressure flow meter

A differential pressure flowmeter, olive-shaped technology, used in the field of pipeline fluid flow measurement, can solve the problem of the relative pressure loss ratio of the spindle flowmeter being too large, achieve speed increase, prevent dirt blockage, and ensure accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

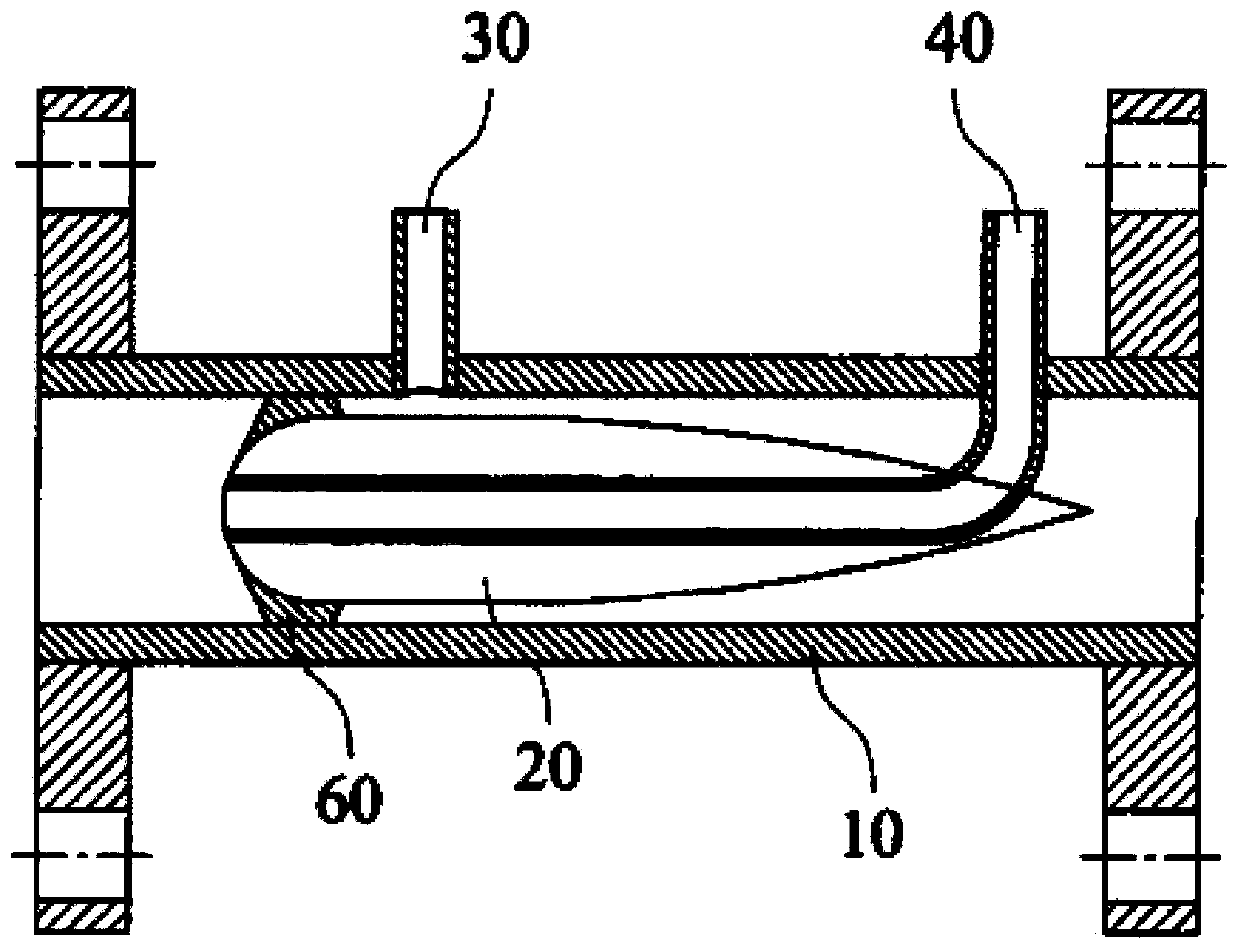

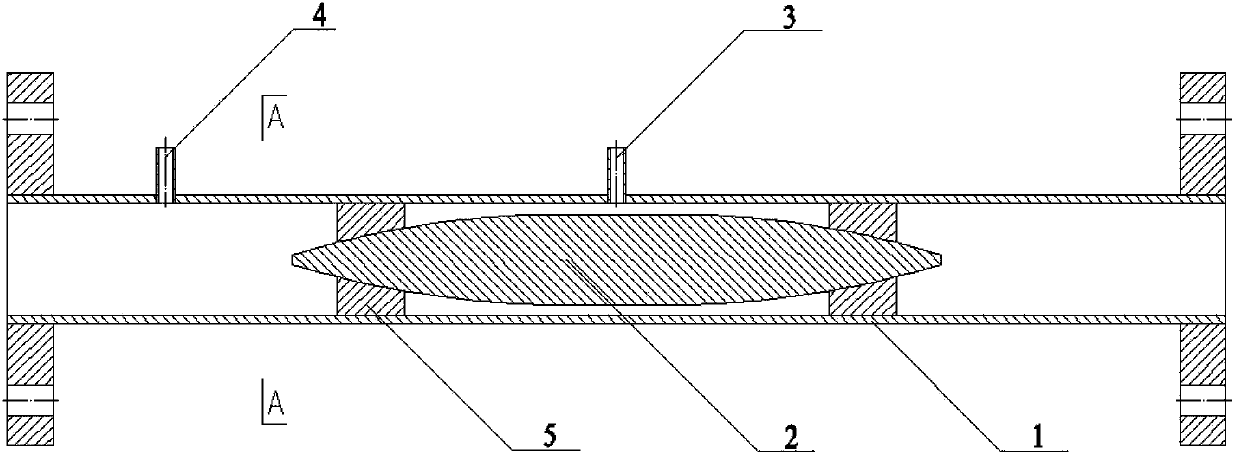

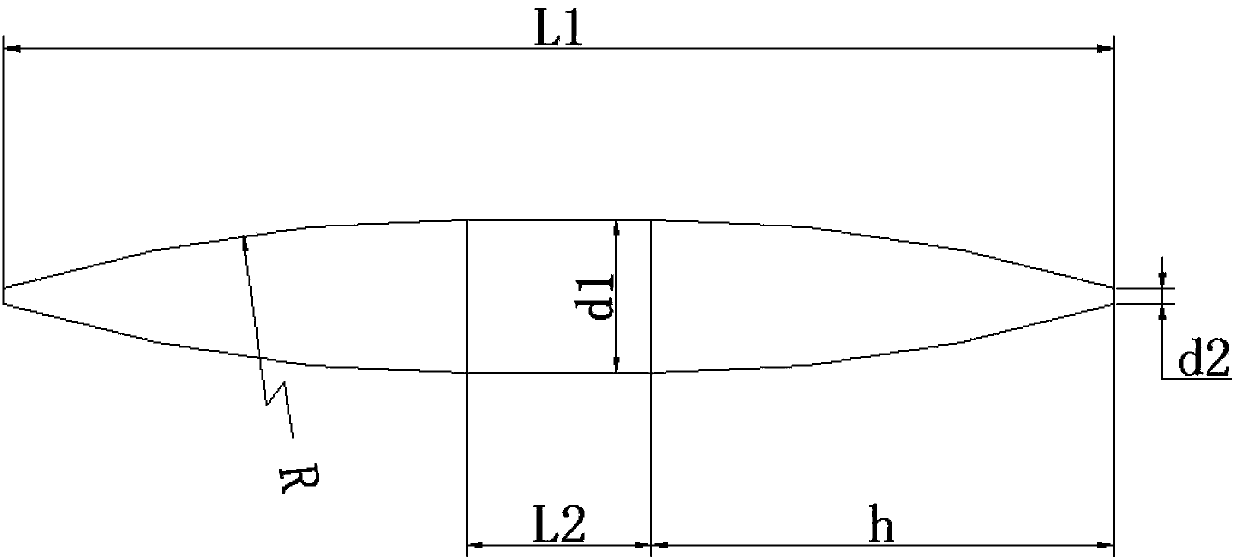

[0025] The technical solution of the olive-shaped differential pressure flowmeter of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] Such as figure 2 and Figure 4 As shown, an olive-shaped differential pressure flowmeter includes a measuring tube 1, flanges connected to both ends of the measuring tube 1, a throttling element 2 arranged in the measuring tube 1, and a front and rear isolation set on the wall of the measuring tube 1. On the high-pressure pipe 4 and the low-pressure pipe 3, four guide fins are evenly arranged on the outer circumferences of the left and right ends of the throttling element 2. The pressure-taking nozzle of the high-pressure pipe 4 is arranged on the pipe wall of the measuring pipe 1 upstream of the detection part. The pressure-taking nozzle of the low-pressure pipe 3 is arranged on the wall of the measuring pipe 1 in the middle of the corresponding cylinder.

[0027] Such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com