Tobacco leaf brittleness detection method

A detection method and technology of tobacco leaves, applied in the preparation of test samples, measuring devices, and mechanical devices, etc., can solve problems that limit the research and application of mechanical properties of tobacco, and achieve the effect of improving processing quality and processing level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

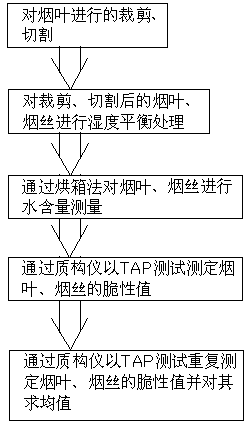

[0020] Such as figure 1 Shown, a kind of detection method that is used for tobacco leaf brittleness comprises the following steps;

[0021] A: The tobacco leaves and shredded tobacco to be tested are cut and cut into regular-sized tobacco leaves or shredded tobacco;

[0022] B: performing humidity balance treatment on the cut tobacco leaves and shredded tobacco; the moderate balance treatment is to put the cut tobacco leaves and shredded tobacco into sulfuric acid dryers with different humidity for humidity balance treatment respectively. Among the present invention, described sulfuric acid drier is, is mixed with distilled water and the concentrated sulfuric acid of 98% the sulfuric acid drier of different humidity, the humidity that prepares the sulfuric acid drier in the present embodiment is 60% and 80%, respectively when humidity is 60% and 80% sulfuric acid desiccators carry out humidity balance treatment for 48 hours (this time is the minimum time required for humidity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com