Non-rotary optical rotation solution gauge and method for measuring specific rotation of optical rotation solution through gauge

A non-rotating, measuring instrument technology, applied in the direction of polarization influence characteristics, etc., to achieve the effect of real-time observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

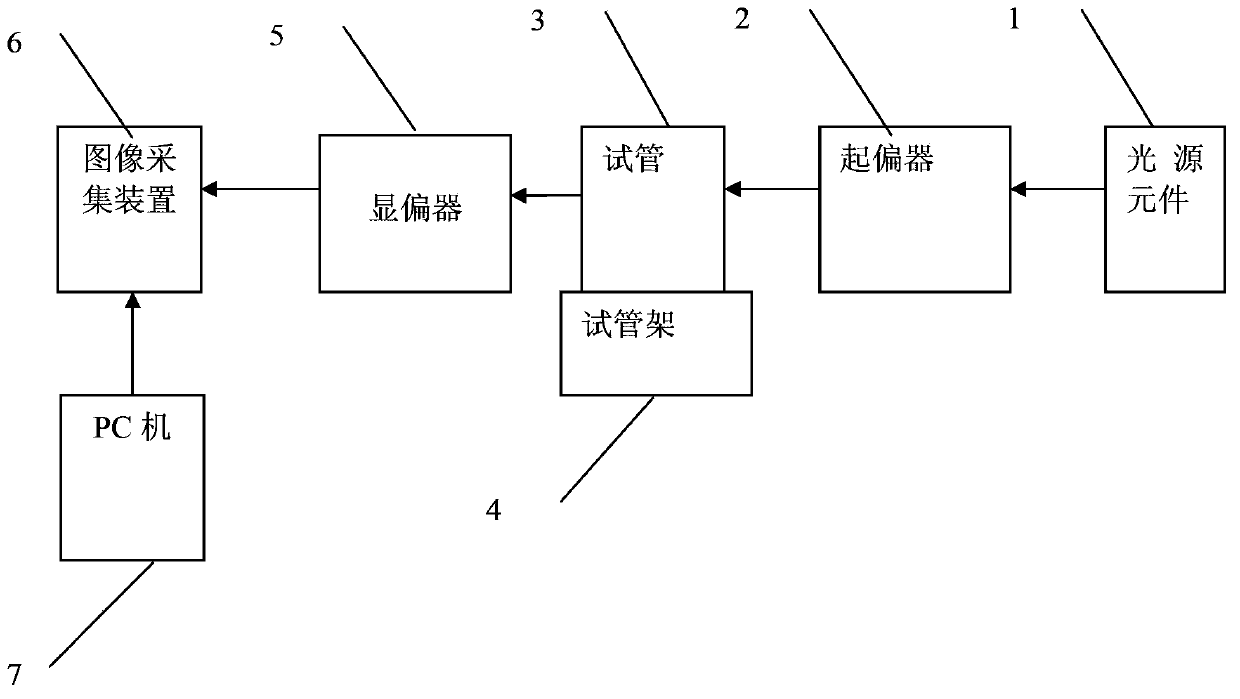

[0023] Specific implementation mode 1. Combination figure 1 Describe this embodiment, the non-rotating polarimetric solution measuring instrument of this embodiment, the polarimeter includes a light source element 1, a polarizer 2, a test tube 3, a test tube rack 4, a polarizer 5, an image acquisition device 6 and a PC 7;

[0024] The light beam emitted by the light source element 1 is incident on the polarizer 2, and the linearly polarized light after being polarized by the polarizer 2 is incident on the test tube 3 containing the optically active solution, and the linearly polarized light after passing through the test tube 3 containing the optically active solution is incident on the The polarizer 4, the polarized light developed by the polarizer 4 is incident on the photosensitive surface of the image acquisition device 6, and the image acquisition device 6 sends the collected image information to the PC 7, and the test tube 3 is installed on the test tube rack 4 Above, t...

specific Embodiment approach 2

[0026] Embodiment 2. This embodiment is a further description of the non-rotating polarimetric solution measuring instrument described in Embodiment 1. The light source element 1 is realized by a laser or an LED light source. Use a laser or LED light source as the incident light source, irradiate on the polarizer, pass through the polarizer, and obtain the polarized direction of the incident light on the PC.

specific Embodiment approach 3

[0027] Embodiment 3. This embodiment is a further description of the non-rotating polarimetric solution measuring instrument described in Embodiment 1 or Embodiment 2. The image acquisition device 6 is realized by a CCD camera.

[0028] The CCD camera is used to display the image of the linearly polarized light after 4 in real time, and the outgoing direction of the linearly polarized light can be accurately obtained through the software processing on the PC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com