Method used for preventing pressure vessels from melting damages caused by molten materials in reactors, and system used for method

A technology for a reactor vessel and a pressure vessel, which is applied in the field of preventing the melt damage of the reactor core melt to the reactor pressure vessel and the nuclear safety field, can solve the problems of insignificant cooling effect, no flow control of cooling water injection, damage to the core, etc., to avoid Adverse interactions, avoid core damage, implement simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

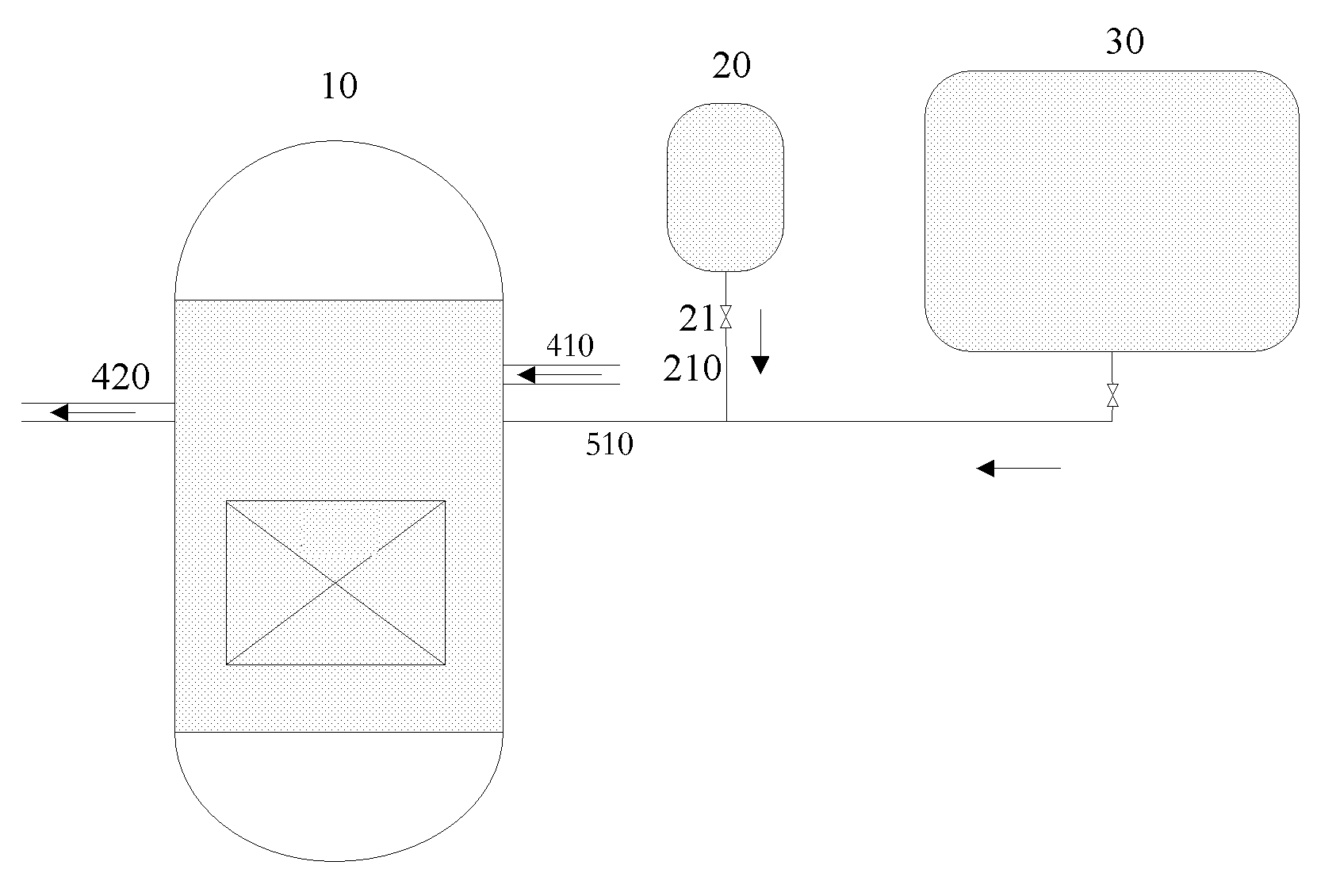

[0042] Such as figure 1 As shown, when the nuclear power plant (power 1400MWe) loses cooling, the ERVC system is immediately started to cool the reactor pressure vessel, and at the same time monitor the core outlet temperature, that is, the outlet temperature at the cooling pipe 420 . When the core outlet temperature monitoring device detects that the core outlet temperature rises to 650°C, the automatic control system (not shown) starts the injection IRVR system in the reactor vessel, opens the valve 21 on the pipeline 210, and injects the IRVR into the IRVR injection box. 28m out of 20 3 The boron-containing aqueous solution is injected into the reactor pressure vessel through the pipeline 210 and the direct injection pipeline 510, and the injection time is about 10 minutes, during which the ERVC system keeps working.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com